Summary Statement

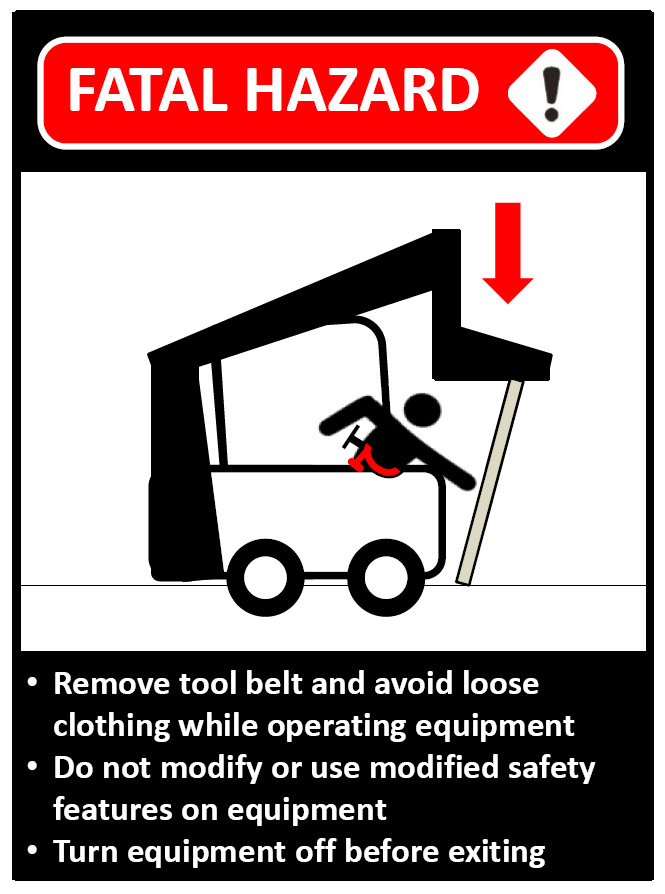

This Oregon-FACE toolbox talk is about a 32-year-old skidsteer operator who died after being crushed by a lift assembly while leaning out of his forklift. The investigators recommended:

1. Staying seated inside the protective cage when operating skid-steer loaders.

2. Turning off equipment before exiting.

3. Avoiding operating equipment if safety systems or features have been modified, or are not working properly.

4. Conducting a check on safety features before use and reporting any

problems.

5. Avoiding loose clothing and remove items, like tool belts, that can interfere with safe operation of equipment.

6. Allowing only trained operators to operate equipment

March 2015

Toolbox Talk Guide

Instructions

1. Display the graphic above to your crew, and read the following:

Our safety talk today is about a 32-year-old skid steer operator who died after being crushed by a lift assembly while leaning out of his forklift. The victim had lifted a load and placed a 2x4 beneath it for stability. He leaned out of his forklift to knock the 2x4 out with his hammer. The hammer did not reach the 2x4 so he leaned out of his forklift to try to knock it out again. His tool belt hit the lift control and the lift assembly lowered on him. His head was crushed between the forklift assembly and the frame of the machine. The seat and safety bar hand an interlock function but may not have been functioning or had been deactivated.

Our safety talk today is about a 32-year-old skid steer operator who died after being crushed by a lift assembly while leaning out of his forklift. The victim had lifted a load and placed a 2x4 beneath it for stability. He leaned out of his forklift to knock the 2x4 out with his hammer. The hammer did not reach the 2x4 so he leaned out of his forklift to try to knock it out again. His tool belt hit the lift control and the lift assembly lowered on him. His head was crushed between the forklift assembly and the frame of the machine. The seat and safety bar hand an interlock function but may not have been functioning or had been deactivated.

So here are some ways we can prevent something like this from happening where we work:

- Stay seated inside the protective cage when operating skid-steer loaders. Turn equipment off before exiting.

- Never operate equipment if safety systems or features have been modified, or are not working properly. Conduct a check on safety features before use and report any problems.

- Avoid loose clothing and remove items, like tool belts, that can interfere with safe operation of equipment

- Management or I must make sure that only trained operators are allowed to operate equipment

2. Ask: “Does anyone have more ideas or comments to share?” Pause for discussion. Then see if there are ways to take action.

- “Do we have any equipment where the safety feature has been deactivated?” What would prevent you from doing a safety check before each use?

- “What do you all do when you see someone with a tool belt or loose clothing while operating equipment?”

- Discuss a similar situation at your current site.

- Express your commitment to training people for each machine they operate.

- Commit to follow-up at the next safety talk.