Summary Statement

Using GFCI (Ground Fault Circuit Interrrupter) outlets can greatly reduce electrocution hazards when working with power tools.

2000

GFCI: A Great Safety Tool

The widespread use

of portable tools on construction sites, particularly when used with flexible

cords, creates the potential for electric shock and even death. This is

because cords, cord connectors, receptacles and cord and plug-connected

equipment are more vulnerable to damage by activities on the job or just

aging, potentially exposing the electric wires. A cord assembly with improperly

connected terminals is also a frequent hazard. Wet conditions, including

wet clothing, high humidity, standing water, or perspiration increase

the risk.

And the risk is high. Even extremely low current can cause death from

respiratory paralysis, if the victim is unable to release the "hot" object

and the current passes through the chest for an extended time. The most

common cause of death from electric shock results from ventricular fibrillation

(loss of the heart's ability to pump, which leads to death within minutes).

If you are on a scaffold or ladder, any shock can cause you to lose your

balance and fall resulting in injury or death.

|

GFCIs (ground fault circuit interrupter) were developed in 1961 to reduce

these hazards, and OSHA requires their use on construction sites for all

120-volt, single-phase, 15 and 20-amp receptacle outlets which are not

part of the permanent wiring of the building or structure. GFCI is a fast-acting

circuit breaker which senses small imbalances in the circuit caused by

current leakage to ground and, in a fraction of a second, shuts off the

electricity. It is much more effective than a standard circuit breaker

or fuse, which are really designed to protect wiring and equipment not

people.

Ground fault circuit protection can be part of a circuit breaker or built

within a receptacle. The circuit breaker protects the entire circuit while

receptacles can be wired to protect only the individual device and/or

to also protect the receptacles on the load side of the GFCI device. Providing

more GFCIs or shorter circuits can prevent tripping caused by the cumulative

leakage from several tools or by leakage's from extremely long circuits.

It is also a good practice to limit exposure of connectors and tools to

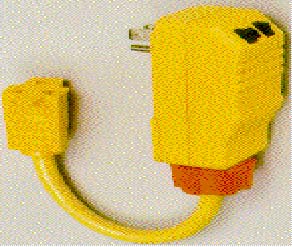

excessive moisture by using watertight or sealable connectors. Portable

GFCIs are also available - use them while waiting for your employer to

comply with OSHA standards.

A portable GFCI you can keep with you

OSHA regulations allow employers on construction sites to maintain an "extensive assured equipment grounding conductor program," including daily inspections and periodic testing by one or more competent persons, as an alternative to the use of GFCI. But because it is impractical to meet all the requirements of a grounding program, GFCI protection is easier and better.

While critical to safety, effective GFCI protection is commonly lacking on construction sites. In 1999, ground fault protection violations on construction sites were the tenth most common reason employers were cited. What is the situation where you work?

Over four hundred workers die each year from contact with electrical energy, the fifth leading cause of workplace death. Construction workers, including laborers, electricians, painters and others account for almost half the total. Direct or indirect contact with power lines is the most common cause of electrocution.