Summary Statement

Provides information on the causes of deaths on various types of aerial lifts, the trades most often involved and suggestions to avoid death and injury.

May 2002

|

Presented

at the 12th Annual Construction Safety & Health Conference &

Exposition, Rosemont, Illinois, May 2002.

|

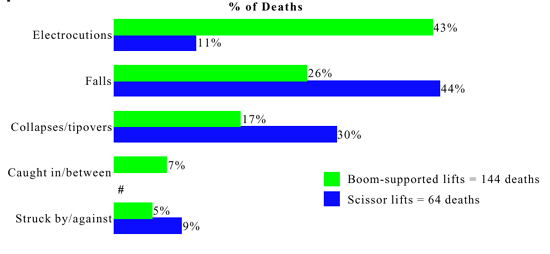

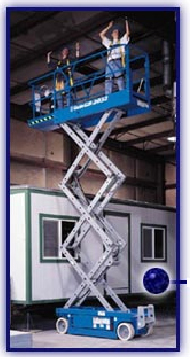

From 1992-99, there were 26 deaths per year from lifts in construction.

- 18 per year from

boom-supported lifts

- 8 per year from scissor and other vertical lifts

This

is 3% of all deaths in construction

Causes of Death from Aerial

Lifts in Construction, 1992-99

#Data for scissor lifts do not meet Bureau of Labor Statistics publication

criteria

Source: U.S. Bureau of Labor Statistics data

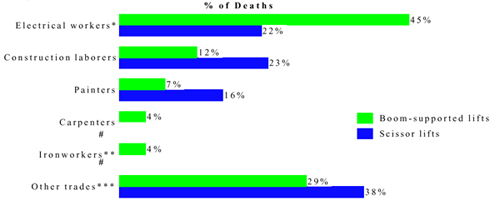

Deaths from Aerial Lifts

in Construction, by Trade, 1992-99

#Data from scissor lifts does not meet Bureau of Lab or Statistics publication

criteria

* Electricians, electrician apprentices, power installers, and their

supervisors

** Structural metal workers and welders and cutters

*** Includes plumbers, pipe fitters and steam fitters, brick masons

and stone masons , drywall installers

Source : US Bureau of Labor Statistics data

Boom-Supported Lifts

Electrocutions

- almost all due to overhead power lines

-

1/2 of electrocutions involved body contact with overhead power lines

-

One-third involved overhead power lines contacting lift booms or buckets

Falls

- 1/2 of fatal

falls involved ejection from the bucket after worker or lifts was

struck by vehicles, cranes or objects.

-

1/6 occurred while transferring to or from the bucket at a height

- 2/5 of deaths

involved collapse of boom

- Almost one-third

were due to tipovers.

- 1/4 involved

collapses of bucket

- Most involved

the worker getting caught between the bucket edge and a roof joist or

beam.

Struck

by/against

- Mostly involved

workers being struck by collapsing materials, girders, etc.

Scissor Lifts

Falls

Falls

- 1/5 of deaths

involved ejections, after being struck by object

- Cause of fall

unknown in 3/5 of deaths

- Other causes included

removal of chains, standing on or leaning over railings

- Caused almost

1/3 of scissor lift deaths

- Mostly while elevated

over 15 feet

- 1/4 of tipovers occurred where lift hit a hole or curb while moving

- 1/2 involved overhead power lines

Renting an Aerial Lift

- Get maintenance

history of aerial lift

- Get operator's manual

and maintenance manual (if separate)

- Ensure a detailed

maintenance check is done before rental

- Make sure operator

controls are easily accessible and properly marked

Operator Training

- Training must

be done by a qualified person experienced with the particular lift model

- Training must

include:

- Nature of

electrical, fall, and other hazards involved in operating lift

- Precautions

for dealing with hazards

- Rated load

capacity for the lift (including workers, tools, materials, bucket

liner, etc.)

- Manufacturer

requirements, as outlined in operator manual

- Demonstration

of skill and knowledge in actual operation of the aerial lift

Qualified Person Definition

- Nature of

electrical, fall, and other hazards involved in operating lift

-

OSHA 1926.450(b)

A qualified person ....by extensive knowledge, training, and experience can....solve....problems related to the subject matter....

Maintenance Requirements

- Training of mechanics

should be done by qualified person experienced with lift model

- Maintenance should

include:

- Knowledge

of manufacturer's maintenance requirements

- Frequent inspections

of aerial lift by qualified mechanic

- At least annual

detailed inspections by qualified mechanic

- Knowledge

of manufacturer's maintenance requirements

- Insulated aerial

lifts have special electrical test requirements

- De-energize and lockout/tagout aerial lift before conducting maintenance and repairs

Before Operating Aerial Lifts

- Do not modify

aerial lift without written permission

- Check safety devices,

operating controls before each use

- Check area in

which aerial lift will be used for:

- Level surface

(Do not exceed manufacturer slope recommendations)

- Holes, drop-offs,

bumps, debris, etc.

- Overhead obstructions

and overhead power lines

- Stable surface

- Other hazards

- Level surface

(Do not exceed manufacturer slope recommendations)

Set outriggers, brakes, wheel chocks

Preventing

Electrocutions

- Non-electrical workers

must stay at least 10 feet away from overhead power lines.

- Electrical workers

must de-energize/insulate power lines or use proper PPE/equipment.

- Use insulated buckets

near overhead power lines

Regularly check insulation on buckets

Preventing Tip-Overs

- Do not exceed

manufacturer rated load capacity limits

- Do not travel

to job location with lift in elevated position.

- Set up proper

work zone protection when working near traffic

- Positioning of

lifts

- Do not drive

near drop-offs or holes.

- Do not raise

platform on uneven or soft surfaces.

- Do not drive

onto uneven or soft surfaces when elevated.

- Do not raise

platform on slope or drive onto slope when elevated.

- Do not raise

platform in windy or gusty conditions.

- Do not drive

near drop-offs or holes.

- Avoid excessive

horizontal forces when working on elevated scissor lifts

Fall Protection

- OSHA regulates

aerial lifts as scaffolds

- 1926.453 Aerial

Lifts only applies to bucket trucks

- Fall protection

is required (full body harness with lanyard or body belt with 2-foot

lanyard as restraint device)

- OSHA does

not require harnesses and lanyards on other boom lifts and scissor

lifts if there are guardrails

- 1926.453 Aerial

Lifts only applies to bucket trucks

- Fall arrest systems

(harness plus lanyard to stop a fall)

- Can tip over

some boom lifts and scissor lifts due to fall stopping force

- Can tip over

some boom lifts and scissor lifts due to fall stopping force

- Fall restraint

systems intended to prevent falls are preferred

- e.g. Full

body harness plus lanyard designed for size of lift platform

- e.g. Full

body harness plus lanyard designed for size of lift platform

- Always close entrance

chains or doors

- Stand on floor

of bucket or lift platform

- Do not climb on or lean over guardrails