Summary Statement

A presentation on the excavation standard, overview of soil mechanics and recognition of excavation hazards. Part of a collection.

June 3, 1996

| These materials were produced by the Division of Safety, Florida Department of Labor and Employment Security, as part of a special OSHA program to reduce work-related deaths in construction in California, Florida, and Texas. Because Florida's funding for the program - CARE, or Construction Accident Reduction Emphasis - ended in June 2000, the materials will not be updated. The materials should be reviewed yearly for any needed changes. |

Objectives

To provide

students with:

- An introduction to 29 CFR 1926,

- Subpart P-Excavation Standard

- An overview of soil mechanics

- An introduction to trenching and excavation hazard recognition

29 CFR 1926, Subpart P

1926.650

- Scope, application,

and definitions applicable to this subpart

- General requirements

- Requirements for protective systems

1926.650 Scope, Application,

and Definitions

- Scope and application

- Definitions

- Competent Person

- Accepted engineering

practices

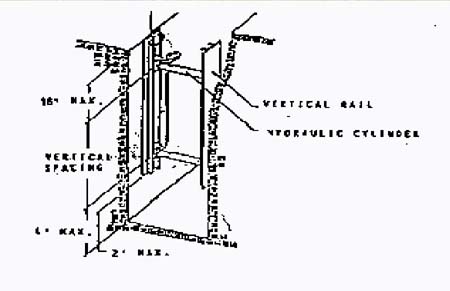

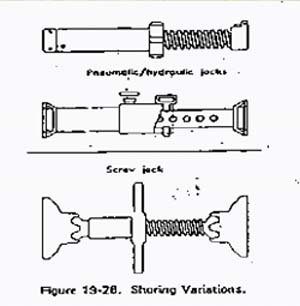

- Aluminum hydraulic

shoring

- Bell- bottom pier

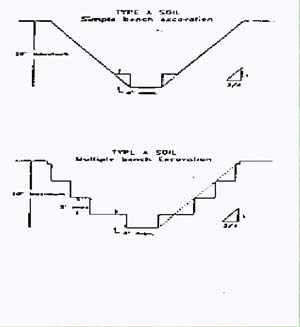

- Benching

- Cave- in

- Competent person

- Cross braces

- Kick- out

- Protective systems

- Ramp

- Registered professional

engineer

- Sheeting

- Shield

- Shoring

- Excavation

- Faces or sides

- Failure

- Hazardous atmospheres`

- Sloping

- Stable rock

- Structural ramp

- Trench.

Definitions

"Excavation" means any:

- Man- made cut

- Cavity

- Trench

- Depression in an earth surface, formed by earth removal.

.Confined space is

a space that, by design and/ or configuration has:

- Limited openings

for entry and exit

- Unfavorable natural

ventilation

- May contain or

produce hazardous substances

- Is not intended for continuous employee occupancy.

"Trench (Trench

excavation)" means a narrow excavation (in relation to its length)

made below the surface of the ground.

- In general, the

depth is greater than the width, but the width of a trench (measured

at the bottom) is not greater than 15 feet (4.6 m).

- If forms or other structures are installed or constructed in an excavation so as to reduce the dimension measured from the forms or structure to the side of the excavation to 15 feet (4.6 m) or less (measured at the bottom of the excavation), the excavation is also considered to be a trench.

Accepted

engineering practices are procedures that are compatible with the standard

practice required of a registered professional engineer.

.Adjacent structure stability refers to the stability of the foundation(

s) of adjacent structures whose location may create surcharges, changes

in soil conditions, or other disruptions that have the potential to extend

into the failure of the excavation or trench.

A competent persons is one who is capable of identifying existing and predictable hazards in the surroundings, or working conditions which are unsanitary, hazardous, or dangerous to employees, and who has authorization to eliminate them.

A competent

person must have specific training in, and be knowledgeable about,

- soils analysis

- the use of protective

systems

- requirements of this standard

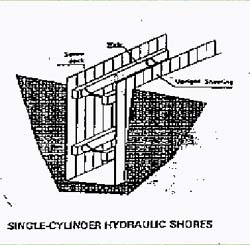

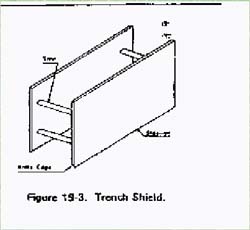

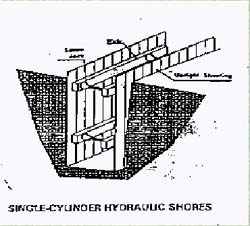

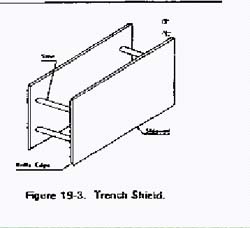

Protective systems

refers to a method of protecting employees from cave- ins, material that

could fall or roll from an excavation face into an excavation, and from

the collapse of adjacent structures.

.

Protective systems include support systems, sloping and benching systems,

shield systems, and other systems that provide the necessary protection.

1926.651 - General requirements

- Surface encumbrances

- Underground installations

- Access and egress

- Exposure to vehicular

traffic

- Exposure to falling

loads

- Warning system

for mobile equipment

- Stability of adjacent

structures

- Protection of

employees from loose rock or soil

- Inspections

- Fall protection

- Hazardous atmospheres

- Protection from hazards associated with water accumulation

1926.651( c)( 2) Means of

egress

.

Means of egress from

trench excavations: .

- A stairway, ladder, ramp or other safe means of egress shall be located in trench excavations that are 4 feet (1.22 mm) or more in depth.

- A means of egress should require no more than 25 feet (7.62 m) of lateral travel for any employee to reach.

1926.651( k)- Inspections

Daily inspections

of excavations, the adjacent areas, and protective systems shall be made

by a competent person for evidence of a situation that could result in:

- Possible cave- ins

- Indications of failure of protective systems

- Hazardous atmospheres

- Other hazardous conditions.

An inspection shall

be conducted by the competent person:

- Prior to the start of work and as needed throughout the shift.

- After every rainstorm or other hazard increasing occurrence.

- These inspections are only required when employee exposure can be reasonably anticipated.

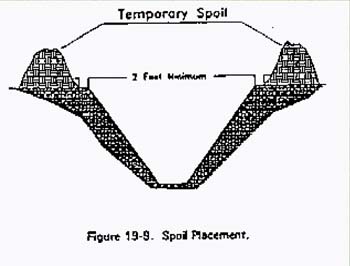

1926.652 - Requirements

for protective systems

- Protection of

employees in excavations

- Design of sloping

and benching systems

- Design of support

systems, shield systems, and other protective systems

- Materials and

equipment

- Installation and removal

1926.652 ( a)- Protection

of employees in excavations

.(1) Each employee

in an excavation shall be protected from cave- ins by an adequate protective

system designed in accordance with paragraph (b) or (c) of this section

except when:

- (i) Excavations

are made entirely in stable rock; or

- (ii) Excavations are less than 5 feet (1.52 m) in depth and examination of the ground by a competent person provides no indication of a potential cave- in.

1926.652 (d)-

Materials and equipment

.(1) Materials and

equipment used for protective systems shall be free from damage or defects

that might impair their proper function.

(3)

When material or equipment that is used for protective systems is damaged,

a competent

person shall examine the material or equipment and evaluate its suitability

for continued use.

If the

competent person cannot assure the material or equipment is able to support

the intended loads or is otherwise suitable for safe use.

- Such material or equipment shall be removed from service.

- Such material or equipment shall be evaluated and approved by a registered professional engineer before being returned to service.

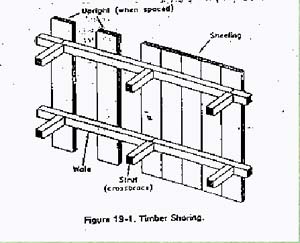

Worker Protection Systems

Appendix A

- Soil Classification

- Sloping & Benching

- Timber Shoring

- Aluminum Hydraulic Shoring

Soil

Testing

OBJECTIVES

Provide

the student with:

- A brief overview

of 29 CFR 1926 Subpart P Excavation Standard

- A Brief Introduction

into Soil mechanics

- A Brief overview of tests they can use in determining soil conditions

Overview: Soil Mechanics

Soil Mechanics

A number of stresses and deformities can occur in an open cut or trench.

For example, increases

and decreases in moisture content can adversely affect the stability of

a trench or excavation.

Following are some of the more frequently identified causes of trench

failure.

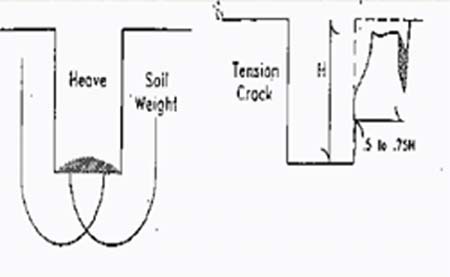

Tension Cracks: Usually form at a horizontal distance of .5 to .75 times the depth of the trench, measured from the top of the vertical face of the trench.

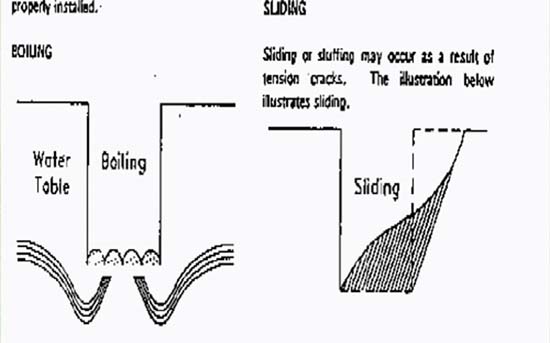

Sliding or Sluffing: May occur as a result of tension cracks.

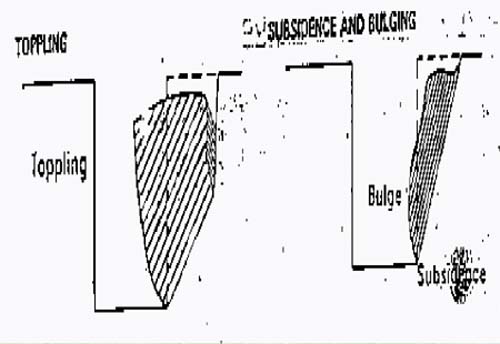

Toppling: In addition

to sliding, tension cracks can cause toppling.

- Toppling occurs when the trench’s vertical face shears along the tension crack line and topples into the excavation.

Subsidence and Bulging:

- An unsupported excavation can create unbalanced stress in the soil, which in turn, causes subsidence at the surface and bulging of the vertical face of the trench.

- If uncorrected, this condition can cause face failure and entrapment of workers in the trench.

Bottom heaving or squeezing is caused by the downward pressure created by the weight of adjoining soil. This pressure causes a bulge in the bottom of the cut.

Heaving and squeezing

can occur even when shoring or shielding has been properly installed.

Boiling is evidenced by an upward water flow into the bottom of the cut.

- A high water table is one cause of boiling.

Boiling produces a “quick” condition in the bottom of the cut, and occur even when shoring or trench boxes are used.

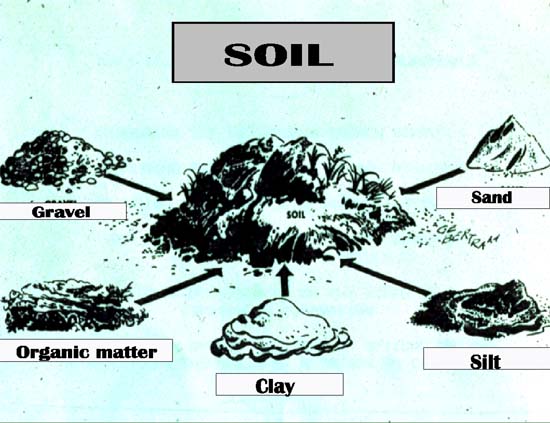

Soil

- Composition

What is Soil ?

Soils - Types

Gravel

- larger than 2 millimeters

- Smaller than 2 millimeters but larger than 0.075 millimeters

- Smaller than 0.075 millimeters but larger than 0.002 millimeters

- Smaller than 0.002 millimeters

Determination of Soil Type

OSHA categorizes soil

and rock deposits into four types. Each type is briefly described below.

Stable rock is natural solid mineral matter that can be excavated with vertical sides and remain intact while exposed.

Black Pine Mine

Slide - Idaho

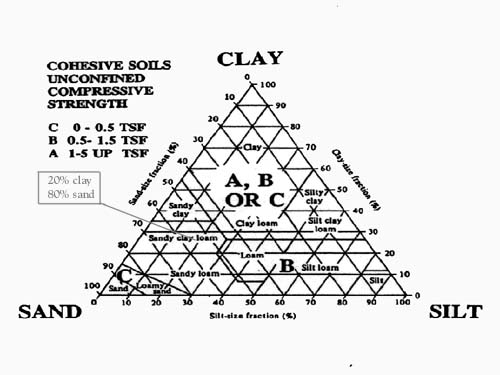

Type A soils are cohesive

soils with an unconfined compressive strength of 1.5 tons per square foot

or greater.

Examples of type

A soils are: clay, silty clay, sandy clay, clay loam, and in some cases

silty clay loam and sandy clay loam.

No soil is type A if it is fissured, is subject to vibration of any type,

has previously been disturbed, is part of a sloped, layered system where

the layers dip into the excavation on a slope of 4H to 1V or greater,

or has seeping water.

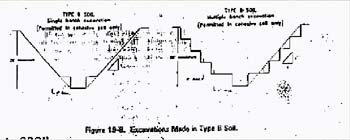

Type B soils are cohesive soils with an unconfined compressive strength

greater than 0.5 tons per square foot, but less than 1.5 tons per square

foot.

Examples are: angular

gravel, silt, silt loam, previously disturbed soils unless otherwise classified

as type C soil.

Soils that meet the unconfined compressive strength or cementation requirements

of type A soils but are fissured or subject to vibration; dry unstable

rock; layered systems sloping into the trench at a slope less than 4H

to 1V ( only if the material would be classified as a type B soil).

Type C soils are cohesive soils with an unconfined compressive strength

of 0.5 tons per square foot or less and include granular soils such as

gravel, sand and loamy sand, submerged soil, soil from which water is

freely seeping, and submerged rock that is not stable.

Type C soils also include in this classification material in a sloped,

layered system where the layers dip into the excavation or have a slope

of 4H to 1V or greater.

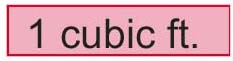

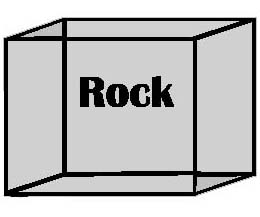

|

|

|

|

|

|

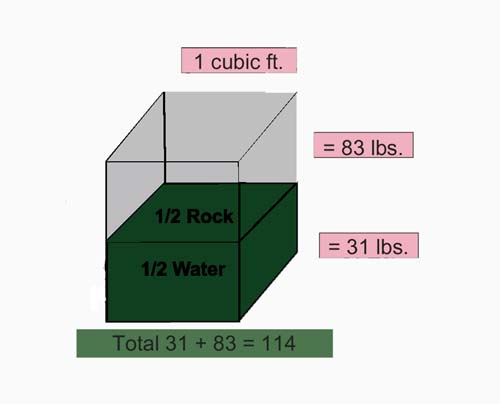

= 167 lbs. |

|

= 62.4 lbs |

|

Specific

Gravity

The ratio of the weight of an object, to the weight of an equal volume of water. |

Soils - Volume

Soils - Cubic

Yard Weight

|

Average soil |

|

Physical characteristics of sand and silt |

|

Soil sample |

|

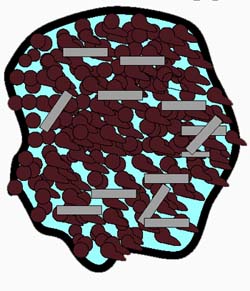

Physical characteristics of clay |

Field Tests

- Documenting field

tests

- Sedimentation

- Ribbon

- Torvane

- Pocket Penetrometer

- Thumb imprint

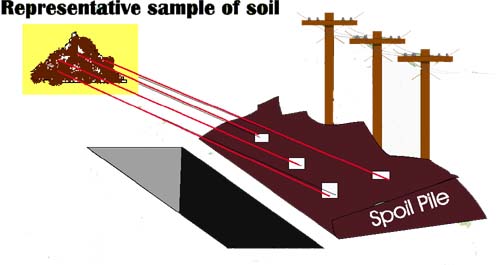

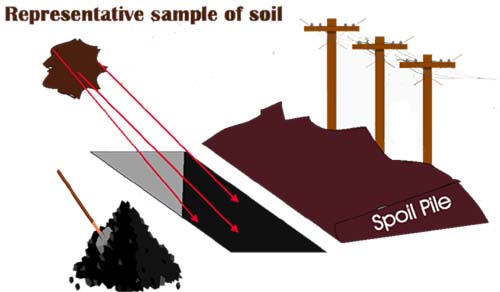

Documenting Field Test

- All Tests

- Representative

sample

- Spoil pile

- Inside the

trench

- Diagram

- Site map

- Record reading

- Soil rating

- Representative

sample

| Soil Sample |

|

Mix it - Quarter it |

Mix it - Quarter it |

Mix it - Quarter it |

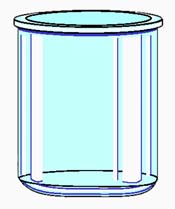

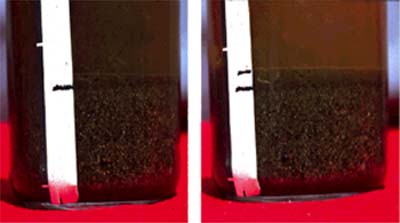

Test # 1 - Field Sedimentation

Test

Test # 1 - Field Sedimentation

Test

- Determines sand content

- Used only on sandy soils

- Sample taken from the spoil pile

- Representative of soil in the excavation

- Fill glass jar

- 5 inches of water on top of soil

- 1 1/2 inches of soil

- Flat bottom container - at least 7 inches high

|

|

|

The Ribbon Test

- Run only on that part of the soil which passes # 40 sieve

- Test shows clay material

- Run on disturbed soil

- Representative sample from spoil pile

- Mix soil + water to make into plastic mass

- Roll mass into cylindrical shape 1/2 to 3/4 inch diameter

- Lay across palm of hand

- Press between thumb and second joint of index finger

- Pass through thumb

- Squeeze until it takes the shape of a 1/8 to 1/4 inch thick strip

- Allow to hang freely from hand

- Clay loam will barely ribbon and break easily

- Clay = relatively long ribbon 6 to 8 inches or more

- More clay = longer and stronger ribbon Silt has tendency to produce short ribbon with broken appearance

|

|

|

Penciling

Test # 3 Torvane Shear Test

Torvane Shear

- Designed to be used on saturated cohesive clay soil

- Vanes are inserted into soil

- Twist and shear soil at base and around circumference of vanes

- Select fresh clod or block of undisturbed soil from spoil pile

- Cut a smooth surface on the clod

- Insert vanes of device into the soil

- Retract vanes to show foot imprint

- Set indicator at zero

- Hold device firmly against soil and twist in clockwise manner until soil fails in shear

|

|

| Consistency Term | Shear Strength, psf | Unconfined Compressive Strength, psf | Soil Type |

| very soft |

<250

|

<500

|

Type C |

| soft |

250-500

|

500-1000

|

|

| medium |

500-1000

|

1000-2000

|

Type B |

| stiff stiff |

1000-1500

1500-2000 |

2000-3000

3000-4000 |

|

| very stiff |

2000-4000

|

4000-8000

|

Type A |

| hard |

>4000

|

>8000

|

Pocket Penetrometer

- Read the unconfined compressive strength at bottom of the red slip ring

- The reading may be 2.0 tons per square foot shear strength

- Which indicate the boundary between stiff and very stiff

- Device is designed to work on saturated clay soil

- Measures unconfined compressive strength of soil

- Twice the value of shear strength of same soil

- Note machine ring about a quarter of an inch

- Push red ring on the barrel all the way toward the handle

- Push shaft into the soil up to the red ring

- Hold barrel so as to not to interfere with the spring inside the barrel

- NOTE slip ring moved on the barrel as barrel was pushed back into the handle

|

|

|

| Consistency Term | Shear Strength, psf | Unconfined Compressive Strength, psf | Soil Type |

| very soft |

<250

|

<500

|

Type C |

| soft |

250-500

|

500-1000

|

|

| medium |

500-1000

|

1000-2000

|

Type B |

| stiff stiff |

1000-1500

1500-2000 |

2000-3000

3000-4000 |

|

| very stiff |

2000-4000

|

4000-8000

|

Type A |

| hard |

>4000

|

>8000

|

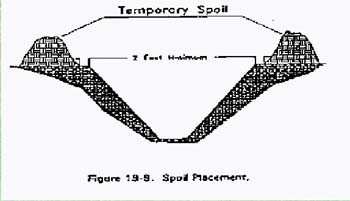

Hazard Recognition Slides