Summary Statement

An analysis of construction worker deaths and disabling injuries to determine whether addressing safety through project design could have prevented the incidents.

January 2006

Acknowledgements

The author wishes to thank Dr. Anthony Veltri and Dr. John Gambatese of Oregon State University. This research study would not have been possible without their support.Abbreviations/Terms

| Constructor | Includes construction firms, contractors, and subcontractors responsible for building a project and employing construction workers |

| Design professional | Includes architects, designers, and design engineers responsible for a project’s design |

| Designing for safety | The consideration of construction site safety in the preparation of plans and specifications for construction projects |

| Disabling injury | An injury that leaves a worker temporarily or permanently disabled |

| FACE | NIOSH Fatality Assessment and Control Evaluation program |

| NIOSH | National Institute for Occupational Safety and Health |

| OSHA | U.S. Occupational Safety and Health Administration |

Contents

Background

Research Methods

Results and Discussion

Conclusions

Recommendations

References

Figure

1. Design - construction incident investigation model

Tables

1. Selection of OSHA accident inspection reports

2. Incidents linked to designing for safety

3. Incidents classified by type of construction project

4. Incidents classified by design element under construction

Annexes

A. Examples of How the Investigation Model Was Applied

B. Existing Design Suggestions Linked to Incidents

C. New Design Suggestions Linked to Incidents

The author analyzed 450 reports of construction workers’ deaths and disabling injuries to determine whether addressing safety in the project designs could have prevented the incidents. The reports were obtained through the Occupational Safety and Health Administration (OSHA) and the National Institute for Occupational Safety and Health (NIOSH). Using an investigation model developed for this research, the author found that in 151 cases (about one-third of those studied), the hazard that contributed to the incident could have been eliminated or reduced if design-for-safety measures had been implemented. The author aims to demonstrate the value of incorporating design considerations into a systems approach to improving safety on construction sites.

Background

Designing for safety is defined as the consideration of construction site safety in the preparation of plans and specifications for construction projects. The process often involves specifying permanent features of a project to address construction worker safety. For instance, parapet walls designed to be at least 42 inches high act as a guardrail and can provide fall protection to construction workers (Gambatese 2005; Trethewy and Atkinson 2003). Designing for safety also encompasses communicating about the safety hazards at the construction work site, for instance, noting on contract drawings the location of existing overhead power lines.

The concept of designing for safety is consistent with the traditional “hierarchy of controls” approach used by safety professionals. This hierarchy calls for eliminating or minimizing a workplace hazard before relying on personal protective equipment or administrative or temporary controls to protect workers (Manuele 1997). Although construction safety professionals view the design-for-safety concept as a viable means of protecting workers, architects and design engineers (together referred to as “design professionals” in this report) are reluctant to adopt this intervention as part of their standard practice (Gambatese 2005). Design professionals lack motivating forces – legal, contractual, or regulatory – to adopt design-forsafety methods. These professionals may also avoid addressing worker safety out of fear that doing so will open them to lawsuits by an injured construction worker (Gambatese 1998; Coble 1997). Moreover, design professionals’ codes of ethics, such as the code established by the American Institute of Architects (2004), set ethical priorities for ensuring final occupant safety and safety of the finished product, but do not address the safety of the workers performing construction.

Regulatory and contractual requirements place the primary responsibility for construction site safety on the constructor. (In this report, “constructor” means the construction firms, contractors, and subcontractors responsible for building a project and employing the construction workers.) For instance, the federal OSHA regulations place the responsibility for worker safety on the constructor as the primary employer. Project owners who make safety a priority also place the responsibility for construction site safety directly on the constructor, by showing preference for pre-qualified contractors who have good safety records, lower insurance rates, and comprehensive safety programs.

Research into the root causes of construction accidents has also focused on the role of the constructor. Abdelhamid and Everett (2000) evaluated construction accidents in the United Michael Behm 2 States and developed a model for tracing the root causes of accidents. Their research addressed activities and conditions at the construction site but did not consider potential root causes in the project concept and design phases. The authors attributed unsafe conditions to four main causes: management action/inaction, unsafe acts of workers and co-workers, events not directly humanrelated (such as equipment failure and natural disasters), and unsafe conditions that are a natural part of the construction site (such as uneven terrain and concealed ditches). Abdelhamid and Everett’s approach is consistent with conventional accident root-cause analysis, focusing solely on the actions and inactions of the constructor, rather than adopting a broader view of accident causality that looks at upstream influences, including the design process.

One recent study of causal factors in construction accidents looked at the designer’s role. Haslam and others (2003) studied the causes of 100 construction accidents in the United Kingdom, and found that permanent works designers (synonymous with “design professionals” in the United States) could have reduced the risk associated with the accidents in almost half of the cases. The authors also developed a construction accident causality model that described immediate causes, shaping factors, and originating influences in construction accidents. They concluded that the permanent works design influences the workers’ activities, the site, and the materials and equipment specified for construction.

Research Methods

The author obtained and analyzed construction accident investigation reports from OSHA State program offices in California, Washington, and Oregon, and from the NIOSH Fatality Assessment Control and Evaluation (FACE) program. These OSHA offices were selected in part because of their proximity to the author at Oregon State University. Also, the reports from these OSHA offices and the FACE data were publicly available at low or no cost. Statistical methods were used to randomly select reports and to analyze the findings. But this study does not claim to be an accurate statistical sampling of all the available data on construction injuries and deaths.

The author initially conducted a pilot review of 25 Oregon OSHA construction accident inspection reports and determined that enough information was available in these reports to link the accident to the design-for-safety concept. For instance, the reports contained detailed notes about the work site hazards and conditions that contributed the incident. A similar review of the FACE data showed that these reports also contained enough information to determine whether there was an association between designing for safety and the construction accidents.

Selection of OSHA Inspection Reports

Oregon and Washington maintain their OSHA inspection reports in a central office, and reports from all districts in these states were included in the analysis. In California, inspection records are maintained individually by each of the 22 California OSHA (Cal/OSHA) field offices in the district where the inspections occurred. Given time and funding limitations, the author chose to obtain records from four Cal/OSHA field offices located near one another (in Torrance, Los Angeles, Anaheim, and Van Nuys). The following criteria were used to conduct a database search of the OSHA inspection reports from the field offices:

- Investigations triggered by an accident reported to OSHA, resulting in a disabling injury or death of a worker (A disabling injury is one that results in the temporary or permanent disablement of a worker.)

- Cases involving firms in Standard Industrial Classifications (SIC) 15 (Building Construction General Contractors), 16 (Heavy Construction Other than Building Construction Contractors), and 17 (Construction Special Trade Contractors)

- Cases designated as "closed" (Open cases are still pending review of the violations or are under a legal review and cannot be accessed.)

- Reports covering the period 2000 to 2002. (Many 2003 cases were still "open" and some field offices archived reports prior to 2000, making them inaccessible to the author.)

Following from this formula, at least 48 cases would be needed from each of the six OSHA offices (286/6 = 48). Fifty cases from each office (except for Torrance, California) were randomly selected from among the cases meeting the search criteria listed above, using the random case selection function of the Statistical Package for the Social Sciences (SPSS). The Torrance office had only 35 case reports meeting the search criteria and all 35 were reviewed. In all, 226 OSHA reports were chosen for the study (see table 1). Cases were rejected because either they lacked information, the accident was deemed not work-related by the OSHA inspector (for instance, death resulting from heart attack), or the actual file was not available. Of the 226 incidents analyzed, 37 had resulted in deaths and 189 had resulted in disabling injuries to workers.

Table 1. Selection of OSHA accident inspection reports

| Office | Cases meeting search criteria | Cases randomly selected | Valid cases used in study |

| Oregon | 108 | 50 | 44 |

| Washington | 62 | 50 | 34 |

| California – Van Nuys | 53 | 50 | 42 |

| California – Anaheim | 147 | 50 | 43 |

| California – Torrance | 35 | 35 | 26 |

| California – Los Angeles | 65 | 50 | 37 |

| Total | 470 | 285 | 226 |

Selection of FACE Data

The FACE program studies deaths resulting from occupational injuries. The program’s goal is to prevent work-related deaths by investigating work situations posing a high injury risk to workers and then formulating and disseminating guidance on prevention strategies (NIOSH 2003). The FACE program selects construction deaths for study based on direct requests from OSHA as well as on FACE’s special-emphasis programs. For instance, recent FACE investigations in the construction industry have targeted Hispanic workers, young workers, steel erectors, and roofers (Virgil Casini, NIOSH, personal communication, Oct. 23, 2003). The complete investigation reports for all industries, including construction, are publicly available on the NIOSH website (http://www.cdc.gov/niosh/face/).

In all, 224 randomly selected FACE reports, obtained from a database of 450 construction accident investigations, were selected for the analysis. FACE reports from 1990 on were used for this study because they contained more details than earlier reports. Each report evaluated in this study was unique and the author verified that there was no overlap between the incidents described in the OSHA inspection reports and those evaluated by the FACE program.

Investigation Model

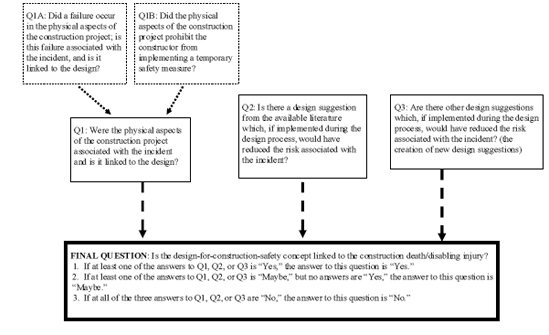

To evaluate the reports selected for review, the author developed a model that aims to provide an objective analysis of possible links between construction incidents and designing for safety (figure 1). In creating the model the author used design-for-safety suggestions developed by Gambatese (1996), and by Gambatese, Hinze, and Haas (1997). The model addressed three questions:

- Did the permanent features of the construction project contribute to the incident? An association with designing for safety was affirmed if the structure failed during construction because it was not designed to withstand construction activities, or if the features of the permanent structure prevented the constructor from implementing a temporary safety device, such as temporary fall protection.

- Could any of the design modifications suggested by Gambatese (1996) and Gambatese, Hinze, and Haas (1997) have been implemented? An association between the incident and designing for safety was affirmed if the author determined that implementing one or more of these design suggestions would have reduced the risk posed to the construction worker or would have facilitated use of temporary safety measures.

- Could the design or the design process have been modified to prevent the incident, in any way not already suggested by Gambatese (1996) or by Gambatese, Hinze, and Haas (1997)?

Figure 1. Design - construction incident investigation model

Here are two examples of how the author applied the investigation model shown in figure 1:

- In a case investigated by OSHA, a residential construction worker died after falling over the side of an unprotected platform at the top of a second story stairway. The author reviewed the report and answered “yes” to all three questions (in figure 1), finding that this incident was linked to the design-for-safety concept. The author determined that implementing the following design suggestion by Gambatese (1996) would have reduced the fall hazard and may have prevented the incident: “design and schedule permanent stairways to be built as soon as possible in the construction phase and used by the construction workers.”

- In an incident described in a FACE report, a construction worker died after tripping and falling through a skylight opening. Applying the model, the author answered “yes” to all three questions and thus determined that this incident was linked to the design-for-safety concept. The author found also that the fall hazard and resulting injury may have been prevented by implementing the following design suggestions by Gambatese (1996): “design domed, rather than flat, skylights with shatterproof glass or add strengthening wires and/or design guardrail protection around skylights.”

Hypothesis Testing

After applying the model and identifying incidents linked to the design-for-safety concept, the author conducted hypothesis testing to determine how the design process or other factors might have affected the incident. For instance, the research sought to determine whether design-linked incidents were related to a specific type of project (residential, commercial, engineering, industrial) or design element under construction at the time of the incident (such as electrical, masonry, and thermal/moisture protection). The aim of this analysis was to identify the designrelated efforts that would be most effective in improving worker safety.

Results and Discussion

Table 2 summarizes the results of applying the investigation model (figure 1) to the OSHA and FACE reports. The research findings linking the incidents to specific design suggestions are presented in annexes B and C. Detailed results of the statistical analysis can be obtained by contacting the author at: behmm@mail.ecu.edu. Also, Behm (2005) contains a more detailed description of the results summarized here.

Table 2: Incidents linked to designing for safety

| Source of reports | Q1: Physical aspects? | Q2: Existing design suggestion? | Q3: New design suggestion? | Is incident linked to design-for-safety concept? | ||||||||

| Yes | Maybe | No | Yes | Maybe | No | Yes | Maybe | No | Yes | Maybe | No | |

| OSHA (n=226) | 4 1.8% |

8 3.5% |

214 94.7% |

40 17.7% |

4 1.8% |

182 80.5% |

27 11.9% |

4 1.8% |

195 86.3% |

48 21.2% |

9 4.0% |

169 74.8% |

| FACE (n=224) | 10 4.5% |

0 0% |

214 95.5% |

78 34.8% |

6 2.7% |

140 62.5% |

42 18.7% |

0 0% |

182 81.3% |

88 39.3% |

6 2.7% |

130 58.0% |

| Total (n=450) | 14 3.1% |

8 1.8% |

428 95.1% |

118 26.2% |

10 2.2% |

322 71.6% |

69 15.3% |

4 0.9% |

377 83.8% |

136 30.2% | 15 3.3% |

299 66.5% |

As table 2 shows, the author linked 48 (21.2%) of the 226 OSHA-investigated incidents to the design-for-safety concept and categorized 9 (4.0%) as “maybe” linked. A greater percentage of FACE cases were found linked to the design: 88 (39.3%) of the 224 incidents were linked and an additional 6 (2.7%) were designated as “maybe” linked to the design.

The author attributes these differences between the OSHA and FACE results mainly to the amount of relevant information found in the reports, which in turn reflects differences in these organizations’ functions. OSHA’s focus in conducting inspections is to determine compliance with regulations and the inspection reports tend to focus on conditions associated with compliance. One of the main goals of the FACE program is to develop injury prevention strategies. The FACE reports typically contained more detailed information on causal factors, and sometimes included mention of the design process, information that was particularly relevant to this study. Among the OSHA reports, more deaths (15 of 37) than disabling injuries (42 of 189) were linked to the design-for-safety concept, a result that could be attributed at least partly to the greater level of detail about work site conditions and overall information in the inspection reports of workers’ deaths.

In nearly half (70) of the total 151 incidents found to be linked (includes “maybe” linked cases) with designing for safety, the deaths and disabling injuries were due to falls. In these cases, the author determined that the incident may have been prevented by implementing permanent fall protection such as the following measure: design special attachments or holes in members at elevated work areas to provide permanent, stable connections for supports, lifelines, guardrails, and scaffolding (Gambatese 1996; Gambatese, Hinze, and Haas 1997).

Electrical hazards were a factor in 18 incidents linked to the design (an incident may be linked to more than one design suggestion). In these cases, the author determined that implementing the following design suggestion may have reduced or eliminated the hazard: disconnect, reduce voltage, or re-route power lines around the project before it begins. In 15 cases, the author found that the following measure could have prevented the incident: locate on contract drawings the existence of overhead power lines and their location in relation to the new structure. Additional study findings are summarized below.

New design modifications and suggestions: Thirty new design-for-safety suggestions have been developed as a result of the analysis (summarized in annex C). For instance, one new suggestion calls for designing fall protection anchor points on storage tank interiors to be used during tank entry for construction and maintenance purposes.

Type of construction project: 210 OSHA reports and 215 FACE reports contained sufficient information to be classified according to type of construction project (see table 3 below). Of these, the author linked 52 OSHA-investigated incidents and 92 FACE cases to the design. Analysis of the OSHA data showed that design-linked construction deaths and disabling injuries were not significantly related to a single type of construction project (p = 0.059, Cramer’s V = 0.188). Analysis of the FACE data also found no significant association between design-linked construction deaths and a single type of construction project (p = 0.214, Cramer’s V = 0.144). These results suggest that the design-for-safety concept can be applied in all types of construction projects.

Table 3. Incidents classified by type of construction project

| Type of project | OSHA | FACE |

| Residential | 69 (32.9%) | 51 (23.7%) |

| Commercial | 78 (37.1%) | 73 (34.0%) |

| Engineering | 41 (19.5%) | 55 (25.6%) |

| Industrial | 22 (10.5 %) | 36 (16.7%) |

| Total | 210 | 215 |

| Incidents linked to design | 52 (24.8%) | 92 (42.7%) |

Design element: As table 4 shows, 208 OSHA reports and all 224 FACE reports contained sufficient information to be categorized according to design element being constructed at the time of the incident. Of these, 151 cases were found to be linked to the design-for-safety concept. Among the OSHA cases, the analysis found that 57 (27.4%) design-linked construction deaths and disabling injuries were related to the design element being constructed at the time of the accident (p = 0.001, Cramer’s V = 0.33). The category of thermal/moisture protection and doors and windows contained significantly more design-linked cases than expected. The author attributed this finding to the relatively large number of deaths and disabling injuries (17) caused by falls from and through roofs and through skylights, where anchorage points, guardrails, and other forms of fall protection, if designed into the permanent structure and used by the constructor, would have prevented the incident.

Table 4. Incidents classified by design element under construction

| Design element under construction | OSHA | FACE |

| Specialties | 2 | 0 |

| Equipment | 4 | 9 |

| Furnishings | 1 | 0 |

| Special Construction | 2 | 0 |

| Conveying Systems | 3 | 4 |

| Mechanical | 13 | 10 |

| Electrical | 17 | 17 |

| Site Work | 64 | 57 |

| Concrete | 11 | 14 |

| Masonry | 3 | 6 |

| Metals | 21 | 30 |

| Wood and Plastics | 23 | 12 |

| Thermal/Moisture Protection/Doors and Windows | 27 | 48 |

| Finishes | 17 | 17 |

| Total | 208 | 224 |

| Incidents linked to design | 57 (27.4%) | 94 (41.9%) |

The analysis of the FACE data also found that the design-linked construction deaths (94 of 224) were related to the design element being constructed at the time of the accident (p = 0.001, Cramer’s V = 0.33). The metals category contributed highly to the significant result. The author attributed this finding to the relatively large number of deaths (20) caused by falls from structural steel framing and buildings, where permanent anchor points, lifeline systems, and other forms of permanent fall protection could have been designed into the permanent features of the constructed building.

Size of firm: Analysis of the FACE reports showed that design-linked construction deaths were not significantly related to the affected company’s size (based on number of employees) or Standard Industrial Classification (SIC). The OSHA-investigated incidents do not report this information consistently and were not included in this analysis.

Conclusions

- Applying the design-for-safety concept can help prevent construction worker deaths and disabling injuries, based on the finding that about one-third (151) of the 450 incidents reviewed for this study were determined to be linked (or maybe linked) to the design.

- In particular, addressing fall protection in project designs can help reduce deaths and disabling injuries, given the large number of design-linked deaths and disabling injuries attributed to falls in this study (70 of 151).

- Design suggestions to prevent hazardous contact with electric and other utilities, such as disconnecting, reducing voltage, or re-routing power lines around the project before it begins, can enhance safety and prevent injuries on construction sites.

- Implementing the design-for-safety concept can benefit new construction, demolition, and renovations alike. Also, applying the concept can improve construction worker safety regardless of the size of the employer or the type of project (residential, commercial, industrial, and engineering).

- The construction industry should implement the concept of designing for construction safety as a standard practice to reduce safety risks to workers. The previously developed design-forsafety suggestions (Gambatese 1996; Gambatese, Hinze, and Haas 1997) and the new suggestions based on this research (see annexes B and C) can provide a foundation for implementing the concept. However, implementing the design-for-safety concept is not a panacea. Rather, it is one element in a systems approach for preventing injuries and deaths among construction workers. Also, the constructor continues to play a critical role in ensuring worker safety and must adhere to the design-for-safety specifications.

- Designers should include fall protection in specifications for roofs, skylights, and structural steel construction.

- Designers should include barriers and other measures that prevent contact with electrical and other utilities.

- Designers should consider incorporating design-for-safety measures in all types of projects (residential, commercial, and industrial) as well as new projects, renovation, and demolition.

- Root-cause accident analysis and other accident investigations should routinely consider whether design-for-safety modifications could have prevented the incident. As safety professionals demonstrate the link between the design-for-safety concept and construction incidents, they will drive its implementation as a method to reduce overall project risk.

- The U.S. Department of Health and Human Services should consider broad-based methods and initiatives to integrate the concept of designing for construction safety into construction projects to achieve their goal of reducing deaths and injuries by 30% by the year 2010 (HHS 2000). These initiatives should include guidance documents on the implementation of the design-for-construction-safety concept, recommendations to OSHA for consensus standards that include design for safety, and funding for further study.

Follow-up research related to the current project should include a second reviewer to evaluate reports, in order to increase the reliability and validity of the results. The author also suggests eliminating “maybe” as a potential response and using only a “yes”/“no” option when applying the model. A Delphi panel (panel of experts) consisting of construction industry professionals could be established to examine the validity of the responses and to determine the feasibility of implementing each linked design suggestion.

Suggestions for future research on designing for safety are as follows:

- The economic benefit of implementing the design-for-safety concept to all construction entities (designer, owner, and constructor) must be further evaluated, in order to provide additional incentives for implementing the concept.

- Project owners increasingly are purchasing owner-controlled insurance programs (OCIPs), which lump together project risks for all parties in an effort to realize economies of scale (Hinze 2001). Research is needed to demonstrate the effectiveness of designing for safety in reducing costs associated with workers’ compensation insurance premiums. Also, incorporating design for safety within an OCIP should be further investigated as a method to reduce overall project risk.

- The model developed for this study should be applied in actual on-site investigations of deaths and disabling injuries. This type of research would enable the gathering of specific design-related information and could test the feasibility of implementing each suggestion. The FACE program, which is well-suited to conduct such investigations, should consider a special emphasis focus on the role of the design in construction deaths.

Abdelhamid, T., and J. Everett. 2000. Identifying Root Causes of Construction Accidents. Journal of Construction Engineering and Management, 126(1): 52-60.

American Institute of Architects. 2004. 2004 Code of Ethics and Professional Conduct. Available: http://www.aia.org/SiteObjects/files/codeofethics.pdf

Behm, M. 2005. Linking Construction Fatalities to the Design for Construction Safety Concept. Safety Science, 43(2005):589-611.

Coble, R. 1997. Knowing Your Role in Construction Safety to Avoid Litigation. Journal of the American Institute of Constructors, 21(3): 25-28.

Cohen, J. 1988. Statistical Power for the Behavioral Sciences (Second ed.). Hillsdale, NJ: Lawrence Erlbaum Associates.

Gambatese, J.A. 1996. Addressing Construction Worker Safety in the Project Design. Unpublished Doctor of Philosophy Dissertation, University of Washington.

- 1998. Liability in Designing for Construction Worker Safety. Journal of Architectural Engineering, American Society of Civil Engineers (ASCE), 4(3): 107-12.

- 2005. Investigation of the Viability of Designing for Safety. CPWR – Center for Construction Research and Training. Silver Spring, MD. May.

Haslam, R., S. Hide, A. Gibb, D. Gyi, S. Atkinson, T. Pavitt, R. Duff, and A. Suraji. 2003. Causal Factors in Construction Accidents (Research Report RR 156). Health and Safety Executive (United Kingdom). http://www.hse.gov.uk/research/rrpdf/rr156.pdf

HHS (U.S. Department of Health and Human Services). 2000. Healthy People 2010: Understanding and Improving Health. Washington, D.C.: U.S. Government Printing Office.

Hinze, J.W. 2001. Construction Contracts. New York: McGraw Hill Companies.

Manuele, F.A. 1997. On the Practice of Safety. New York: John Wiley and Sons, Inc.

NIOSH (National Institute for Occupational Safety and Health). 2003. NIOSH Fatality Assessment and Control Evaluation Program, NIOSH Publication No. 2003-146 (PB 2003-106-834).

- 2004. Fatality Assessment and Control Evaluation website. Division of Safety Research. http://www.cdc.gov/niosh/face/ [2004, January - April].

Annex A. Examples of How the Investigation Model Was Applied

This section presents examples of how the author applied the investigation model (shown in figure 1 of the report) in deciding whether the incidents described in the OSHA and FACE reports were linked to the design-for-construction-safety concept.

Structural Failure (Question 1)

In the example that follows, question 1 was answered “yes” because the structure itself failed during construction activities and its collapse could be linked to the design process. An employee was working in a crane next to a brick wall, removing roof sections attached to the brick wall. The brick wall was not designed to be free-standing. When the roof section was removed, the brick wall collapsed onto the crane and crushed the worker. This incident review led the author to propose the following new design-for-construction-safety modification: before demolishing and renovating any structure, ensure that an engineering survey is performed by a competent person to determine the condition of the structure, evaluate the possibility of unplanned collapse, and plan for potential hazards.

Question 1 was answered “yes” in the following incident review because the physical aspects of the project prohibited the constructor from implementing effective temporary safety measures. Two employees were walking on the roof of an industrial building to access electrical equipment needing repair when they fell through the roof. The roof had contained many corrugated fiberglass panels (non-load bearing) that were indistinguishable from panels designed as a walking surface and the employees fell through these panels. This design prohibited the constructor from recognizing a hazard and from implementing a temporary safety measure or utilizing a different technique to perform the work. The author concluded that a designer using a design-for-safety approach would have taken into account the construction and maintenance work on the roof and would have provided for an appropriate walking surface for such activities.

Question 1 was answered “no” in this example: The FACE program investigation team determined that one of the main causes of a structural collapse leading to the workers’ deaths was the constructor’s failure to adhere to design specifications. The incident occurred while iron workers were fabricating a steel skeleton for an automotive repair shop. The building plans and procedures specified that ¾-inch steel sway bracing rods be installed and kept in place immediately after hoisting the beams into place for the purposes of maintaining structural stability. The author determined that this incident was not directly design-related; rather the constructor failed to comply with the design specification. This case highlights the critical importance of the constructor’s role in implementing designing-for-safety specifications.

Existing Design Suggestions (Question 2)

The following example demonstrates how a previously developed design suggestion (see complete list in annex B) was linked to a construction incident. An employee laying insulation on a flat roof stepped backwards and fell off the roof edge 30 feet to the ground. The author linked the following two design suggestions to this incident:

- Design the parapet to be 42 inches tall. A parapet of this height will provide immediate guardrail protection and eliminate the need to construct a guardrail during construction or future roof maintenance

- Design special attachments or holes in members at elevated work areas to provide permanent, stable connections for supports, lifelines, guardrails, and scaffolding.

The author developed 30 new design suggestions based on the research; these are summarized in annex C. The section below discusses the development of this new suggestion: design anchor points on the interior of the tank for construction and maintenance purposes.

The author developed this suggestion after extracting the following information from a FACE report (90-16): A small construction company, which had been contracted to sandblast and paint the interior of a tank, planned to use suspension scaffolding to reach all sections of the 48-foothigh and 30-foot-diameter tank. Before the suspension scaffold was raised into position, the victim used a ladder to weld steel brackets to the walls at the top of the tank. The brackets were intended to anchor a horizontal steel cable serving as a fall protection anchor cable. The nylon suspension ropes, which were used in the suspension scaffold system, were lying on the floor of the tank while the brackets were being welded. After the welding, the owner inspected the suspension ropes but did not notice any damage; however, the suspension rope broke when the employee pulled it to move the scaffold higher. The scaffold failed and the employee fell 40 feet to the bottom of the tank.

The FACE study found numerous causes for this accident. One cause was the employee’s failure to follow the OSHA regulation prohibiting welding, burning, riveting, or open flame work on staging suspended by means of fiber or synthetic rope [29 CFR 1926.451(a)(18)]. An OSHA investigation after the incident determined that the rope had broken at a point where it had been burned, probably because the rope was on the ground below where the worker had been welding the anchor points. However, the author also determined that another factor could be linked to the design-for-safety concept: If there had already been anchor points designed-in to the tank’s interior, the employee would not have been required to field-fabricate the anchor points, thus eliminating one of the main hazards associated with the incident.

The FACE review states:

- “Permanent structures of this type are known to require extensive maintenance when they are designed. It is essential that designers/owners of these facilities incorporate appropriate anchor points on tanks to which workers can adequately secure scaffolds and lifelines. Omission of designed anchor points causes workers to improvise anchors or not use them at all. This increases the possibility that a scaffold will be erected using improper procedures and components.” (NIOSH FACE Report 90-16)

Annex B. Existing Design Suggestions Linked to Incidents

The design suggestions presented in this section were originally developed by Gambatese (1996). The concept of designing for construction safety includes modifications to the permanent features of the project and preparation of plans and specifications for construction in such a way that construction site safety is considered. It also includes hazard control and communication of risks regarding the design in relation to the site and the work to be performed. The research findings linking the incidents described in the FACE reports and OSHA reports to these design suggestions are presented below.

| Design suggestion | NIOSH FACE reports | OSHA reports | Total |

| Design special attachments or holes in members at elevated work areas to provide permanent, stable connections for supports, lifelines, guardrails, and scaffolding. | 47 | 23 | 70 |

| Disconnect, reduce voltage, or re-route power lines around the project before it begins. | 13 | 5 | 18 |

| Include the name, address, and telephone number of local utility companies on the drawings. | 12 | 4 | 16 |

| Locate on contract drawing the existence of overhead power lines and their location in relation to the new structure. | 10 | 5 | 15 |

| Design columns with holes at 21 and 42 inches above the floor level to provide support locations for lifelines and guardrails. | 7 | 4 | 11 |

| Provide permanent guardrails around floor openings. | 4 | 6 | 10 |

| Design domed, rather than flat, skylights with shatterproof glass or add strengthening wires. Design guardrail protection around skylights. | 6 | 1 | 7 |

| Design the parapet to be 42 inches tall. A parapet of this height will provide immediate guardrail protection and eliminate the need to construct a guardrail during construction or future roof maintenance. | 6 | 0 | 6 |

| Review the condition and integrity of the existing structure and indicate any known hazards or deficiencies on the contract drawings. | 4 | 2 | 6 |

| Design and schedule permanent stairways to be built as soon as possible in the construction phase and used by the construction workers. | 2 | 1 | 3 |

| Minimize the amount of night work. | 0 | 3 | 3 |

| Design perimeter beams and beams above floor openings to support lifelines (minimum dead load of 5400 lbs.). Design connection points along the beams for the lifelines. Note on the contract drawings which beams are designed to support lifelines, how many lifelines, and at what locations along the beams. | 2 | 0 | 2 |

| Design the slope, width, height, turning radius, and surface treatment of traffic surfaces with consideration of the anticipated size, weight, and maneuverability of the construction equipment. | 2 | 0 | 2 |

| During road work, slow down the ongoing traffic as much as possible by closing down adjacent lanes, posting flag-people to control traffic, or running lead cars to guide the adjacent traffic. | 1 | 1 | 2 |

| Indicate on the contract drawings the locations of existing underground utilities and mark a clear zone around the utilities. | 0 | 2 | 2 |

| Note on the drawings the source of information and level of certainty on the location of underground utilities. | 0 | 2 | 2 |

| Orient the project layout or grade the site accordingly to minimize the amount of work on steep slopes. | 1 | 0 | 1 |

| Design the finished floor around mechanical equipment to be at one level (no steps, blockouts, slab depressions, etc.). | 1 | 0 | 1 |

| Allow for pedestrian traffic to be isolated from construction vehicular traffic. | 1 | 0 | 1 |

| Design and schedule materials and equipment to be painted and/or insulated prior to erection or placement. | 1 | 0 | 1 |

| Allow adequate clearance between the power lines and the structure. | 1 | 0 | 1 |

| Employ police officers to patrol around the project site to help with traffic control. | 1 | 0 | 1 |

| For pre-cast concrete members, provide inserts or other devices to attach fall protection lines. | 1 | 0 | 1 |

| Re-route the power lines around the project site before construction begins. | 1 | 0 | 1 |

| Avoid road work and maintenance during peak traffic volume periods of the day. | 1 | 0 | 1 |

| For access doors through floors, use doors that immediately provide guarded entry around the hole perimeter when the door is opened. | 1 | 0 | 1 |

| Design members which are of consistent size, light weight, and easy to handle. | 1 | 0 | 1 |

| Avoid stair landings constructed separate from the stairs. | 1 | 0 | 1 |

| Consider using prefabricated stairways which can be erected as one assembly. | 1 | 0 | 1 |

| Design and schedule safe tie-ins to existing utilities. | 1 | 0 | 1 |

| Ensure that the electrical system design meets all National Electric Code requirements and the requirements of National Fire Protection Association. | 1 | 0 | 1 |

| Consider using pre-fabricated metal timber fasteners for wood connections instead of end nailing or toe nailing. | 0 | 1 | 1 |

| Design handrails and top rails of a stairrail system to withstand at least 200 pounds applied within 2 inches of the top edge in any downward or outward direction, at any point along the top edge. | 0 | 1 | 1 |

| Design and schedule handrails, guardrails, and stairrails to be erected as part of the structural steel erection. | 0 | 1 | 1 |

| Provide a guardrail along the perimeter of the tank roof. | 0 | 1 | 1 |

| Provide connection points for lifelines at the center of the tank roof. | 0 | 1 | 1 |

| Consider the erection process when designing and locating member connections. | 0 | 1 | 1 |

| Consider alternative steel framing systems which reduce the number of elements and where beams are landed on supports rather than suspended between them. | 0 | 1 | 1 |

| Avoid performing road work on Friday and Saturday nights. | 0 | 1 | 1 |

| Detour public traffic around the project site. | 0 | 1 | 1 |

| To prevent accidents resulting from tired construction workers, do not allow schedules which contain sustained overtime. | 0 | 1 | 1 |

| In embankments directly adjacent to the road edge, provide an initial bench at the road grade to provide room for crews to work. | 0 | 1 | 1 |

| Provide structural support at the edge of roadways to keep heavy construction equipment from crushing the edge and overturning. | 0 | 1 | 1 |

| Totals | 131 | 71 | 202 |

Annex C. New Design Suggestions Linked to Incidents

The findings linking the incidents described in the FACE reports and OSHA reports to new design suggestions are presented below. The author developed the new suggestions while applying the investigation model (in figure 1) to the reviewed incidents.

| New design suggestion | NIOSH FACE reports | OSHA reports | Total |

| Design appropriate and permanent fall protection systems for residential roofs to be used for construction and maintenance purposes. Consider permanent anchorage points, lifeline attachments, and /or holes in perimeter for guardrail attachment. | 9 | 9 | 18 |

| Design appropriate and permanent fall protection systems for commercial roofs to be used for construction and maintenance purposes. Consider permanent anchorage points, lifeline attachments, and/or perimeter holes for guardrail attachment. | 7 | 4 | 11 |

| When design features, such as ventilation systems, trash chutes, chimneys, and elevators, cause floor openings to occur during construction, provide a warning in the plans and specifications for construction, and design in permanent guardrail systems and sequence them in early in the construction process for use by all contractors. | 4 | 3 | 7 |

| Before demolishing and renovating any roof structure that is damaged, ensure that an engineering survey is performed by a competent person to determine the condition of the roof, trusses, purlins, and the structure itself to evaluate the possibility of the structure and its components failing during the work, and to evaluate how fall protection devices will be incorporated into a damaged structure. | 3 | 2 | 5 |

| For tower type structures, design a cable-type lifeline system into the structure that allows workers to be hooked onto the structure and allows for their movement up and down the structure. | 4 | 0 | 4 |

| Design scaffolding tie-off points into exterior walls of buildings for construction and renovation purposes. | 2 | 2 | 4 |

| Design and schedule handrails, guardrails, and stairrails to be built as part of the erection process. | 1 | 2 | 3 |

| Before demolishing and renovating any structure, ensure that an engineering survey is performed by a competent person to determine the condition of the structure, evaluate the possibility of unplanned collapse, and plan for potential hazards. | 2 | 0 | 2 |

| Design appropriate tank anchor points on the interior of the tank for construction and maintenance purposes. | 1 | 1 | 2 |

| Consider the existing site and its potential hazards in relation to the heavy equipment required to perform the scope of work. Provide a warning and information to constructors. | 0 | 2 | 2 |

| Design appropriate and permanent fall protection systems for inside elevator shafts to be utilized during construction and maintenance. Consider anchorage points and lifeline attachments. | 0 | 2 | 2 |

| Consider alternative methods for pouring concrete when specifying concrete pours below or next to overhead power lines, such as the use of a pumping truck. | 1 | 0 | 1 |

| Consider pre-fabricating work stations and fall protection systems into the constructed structure. | 1 | 0 | 1 |

| Provide warning through the plans and specifications when electrical systems create floor openings. | 1 | 0 | 1 |

| Specify the need for a permit-required confined space program when utilizing flammable materials inside tanks. | 1 | 0 | 1 |

| When specifying roofing materials which are not suitable for walking, such as corrugated fiberglass panels, ensure they are distinguishable from safe secure walking surfaces on the roof, or install guardrails around the surfaces not suitable for walking. | 1 | 0 | 1 |

| When designing an atrium in a building, design permanent guardrails, anchor points, or other such fall protection mechanisms so they are sequenced early in to the schedule to allow their use by construction workers. | 1 | 0 | 1 |

| Where job site access is limited, consideration should be given to alternating work schedules or short term interruption of work tasks to allow additional clearance for crane set-up and use. | 1 | 0 | 1 |

| Do not design elevated exterior structures, equipment, etc. next to roof edges. | 1 | 0 | 1 |

| Design periodic turnouts into long straight roadways. This allows trucks to turn around, minimizes reverse motion, and allows for passing of other vehicles. | 1 | 0 | 1 |

| the flaggers, establish an alternate layout of the work zone, such as closing additional lanes of the highway. | 1 | 0 | 1 |

| For projects that occur on or near steep slopes, provide a warning and information about the site conditions in the construction documents. | 1 | 0 | 1 |

| In the design of commercial and industrial buildings, consider if sheet metal could be utilized as a walking surface (either intentionally or unintentionally), and specify appropriate sheet metal gauge for walking and the appropriate screws for strengthening. | 1 | 0 | 1 |

| During highway construction activities, posted speed limits should be reduced and strictly enforced to increase the safety of highway workers. | 1 | 0 | 1 |

| Consider that structural members can be utilized as work areas during construction, and design for their stability. | 0 | 1 | 1 |

| Consider the environmental conditions and the other construction work occurring near trenching and how it will affect the condition of the trench. | 0 | 1 | 1 |

| Do not specify trenching activities adjacent to existing structures. Review how the specified trenching activities will affect the adjacent structure. | 0 | 1 | 1 |

| Evaluate soil conditions, provide that information, and specify proper trenching and shoring based on the conditions in relation to the specified work. | 0 | 1 | 1 |

| Consider electrical conduit/wiring and sequence it in before permanent ceilings or walls are constructed which would limit access during installation. | 0 | 1 | 1 |

| Design wood framed walls to be no more than 8 feet high; when higher walls are specified, provide a warning to the constructors to not lift these higher walls manually. | 0 | 1 | 1 |

| Totals | 46 | 33 | 79 |

1 Cohen (1988) recommends a sample size of 214 cases for a chi-square test of independence (alpha = 0.05, power = 0.80, effect size = 0.30, and df = 16).