Summary Statement

Short description of factors to consider when selecting a full-body fall protection harness, such as comfort, safety, and ability to don and doff easily.

Sep/Oct 2001

What makes one worker wear the proper fall-protection equipment, and use

it in the correct manner while another may not? On one hand, workers must

receive the proper

training on adjusting, inspecting and maintaining the equipment. On the

other hand, no matter how thorough the training, a worker might leave

the equipment behind if it isn't comfortable.

proper

training on adjusting, inspecting and maintaining the equipment. On the

other hand, no matter how thorough the training, a worker might leave

the equipment behind if it isn't comfortable.

Harnessing Size

Many manufacturers rely on universal sizing — which means a harness should fit the average person. However, universal sizing is designed to fit most — not all — workers.Some harnesses have a minimum adjustment on the chest strap that is unusable by shorter workers. The ability to adjust a harness correctly is important, but some manufacturers' adjustable straps are complicated. Employees may have trouble adjusting the leg straps or they may have the D-ring adjusted improperly.

Because some harnesses may cut and pinch when tightened, workers sometimes wear their harnesses too loose in trying to achieve a comfortable fit. One solution is a full-body harness with stretchable webbing that allows workers to flex and bend. There are even stretchable harnesses designed especially for women. All of these design features have been developed to ensure PPE comfort.

How safe is the safety harness?

Most buyers would expect a harness to meet specific safety standards, but surprisingly, some brands don't. Before purchasing fall-protection products, ask these questions:

-

Where

are the products manufactured? Does the facility have ISO 9001 certification?

ISO 9001 certification proves facilities meet strict international standards

in quality assurance for design, development, production, installation

and service.

Where

are the products manufactured? Does the facility have ISO 9001 certification?

ISO 9001 certification proves facilities meet strict international standards

in quality assurance for design, development, production, installation

and service.

- Do the products meet ANSI and CSA standards? Not all harnesses meet ANSI standards, even though they may be labeled as meeting these standards.

- Does the fall protection manufacturer have a Statistical Process Control (SPC) program? Fall-protection products are only as good as the quality of the raw materials/ components.

- Does the manufacturer participate in Safety Equipment Institute (SEI) or any other recognized third-party testing of their products?

- Does the manufacturer have qualified engineers who design and test products? Ask for documented results for dynamic drop tests and static load tests.

Harness construction is anything but standard. Some harnesses are manufactured without a back strap. In the event of a fall, the person may actually fall out of the back of the harness. Chest straps should be easy to adjust, and must withstand a fall without tearing or breaking. In test cases with inferior quality harnesses, some chest straps have broken from fall forces.

Hardy hardware that's comfortable

A harness should have hardware that's sturdy, but not oversized and awkward. At the same time, connecting devices (shock-absorbing lanyards) should attach easily to the hardware. For example, the D-rings on some harnesses are so small that attaching a lanyard can be a tricky process. Harness hardware also poses a hazard if it has sharp edges. The edges can cut into harness webbing, or can be positioned in such a way that they dig into the skin in the event of a fall. To protect workers from hardware injuries, the components must be appropriately manufactured and assembled.

Hardware with exposed springs should be avoided. Exposed springs, especially on friction buckles, can be easily disabled or removed. Reliable hardware construction is important, and should be certified to meet the requirements set forth in ANSI Z359.1 and CSA standards.

|

|

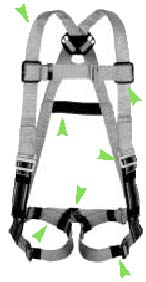

| 1. Hold harness

by back D-ring. Shake harness to allow all straps to fall in place. 2. If chest, leg and/or waist straps are buckled, release straps and unbuckle at this time. 3. Slip straps over shoulders so D-ring is located in middle of back between shoulder blades. 4. Pull leg strap between legs and connect to opposite end. Repeat with second leg strap. If using a belted harness, connect waist strap after leg straps. Waist strap should be tight, but not binding. 5. Connect chest strap and position in mid-chest area. Tighten to keep shoulder straps taut. 6. After all straps have been buckled, tighten all buckles so that harness fits snugly but allows full range of movement. Pass excess strap through loop keepers. Remember, harness styles vary; always refer to instructions enclosed with the harness. (By Douglas Mercier, Dalloz Safety). |

Avoiding tangled webs

Webbing may seem like an innocuous item that would be similar in all cases, but it varies drastically from brand to brand. Some harnesses use webbing that folds over and tangles, and that can be as frustrating as handling a tangled telephone cord. Harness webbing should be sturdy, and the yarns should be tightly woven so the webbing slides easily through the hardware. If webbing snags when it glides under hardware, it can result in cuts to the webbing. Once cut, the harness must be taken out of service.

Examining harness webbing is extremely important. Excessive abrasion will cause webbing to fray and pucker, eventually ending the service life of the harness. Stitching is just as important as the structural integrity of the harness. The stitching must not rip away during a fall.

Harness webbing should resist the effects of sun, heat and moisture for an extended period of time. If a harness is used in an electrical environment, it must also resist conductivity. If it's used in a harsh chemical environment, the webbing must be able to resist toxic chemical fumes and splashes.

Pliable padding

Padding is meant to make the harness more comfortable, but if it's difficult to adjust or is made of material that becomes brittle in cold weather, it can become another problem that discourages proper use of the harness.

How does the harness work?

It sounds too simple to address, but clear, easy-to-read instructions should accompany every harness. In the best-case scenario, the instructions will be in more than one language — English, French and Spanish, for example. All instructions should include explicit guidelines for usage, maintenance and inspection.

It all adds up to safety

When purchasing a harness, make sure you buy the correct harness for the appropriate application. Remember, employees will more readily and properly wear a comfortable harness that easily adapts to lanyards and other connecting devices. The more comfortable the harness, the better your company's chances of employees wearing them, and that increases safety and regulatory compliance, and most importantly saves lives.

ABOUT THE AUTHOR

Douglas Mercier is senior product manager for Dalloz Fall Protection, a leader in manufacturing fall-protection equipment, and in training and engineered systems. The ISEA member company has been manufacturing fall-protection products for more than 50 years in Franklin, PA. Mercier may be contacted at (814)432-2118, ext. 1028, or dmercier@dallozsafety.com.