Summary Statement

Article offers a brief guide to the types of available respirators as classified by NIOSH and which hazards each is designed to address.

New classifications help match protection to hazard

In the United States, NIOSH (the National Institute for Occupational Safety and Health) introduced new requirements for particulate filters in 1998. The new rules upgrade the respirator filters in use, providing better protection against all sizes of particles in the workplace. NIOSH has exclusive authority to certify most respirators. NIOSH standards are referenced in Canadian codes and regulations.

Oil droplets in the air have been found to ruin the filtering ability of some filter material. To ensure that a suitable filter is being used, particulate filters now have an N, R, or P designation (Not resistant to oil, Resistant to oil and oil-Proof). R or P filters should be used when oil is present.

Previously the particulate filters used on air-purifying respirators were broken down into dust/mist, dust/mist/fume, and HEPA cartridges. Now non-powered air-purifying particulate filters are divided into three levels of efficiency (95%, 99% and 99.97%). All three of the new filters will outperform the dust/mist and the dust/mist/fume filters used in the past.

The N series of filters (Not resistant to oil) is appropriate for all airborne solids (particulate) when there are no oil-based products also in the air.

The R series (Resistant to oil) should only be used for an 8-hour shift when solvent or oil mist is present in the air. This filter resists oil but may break down in contact with oil or solvent over a long time.

When using P series filters (oil-Proof), check the manufacturer's recommended service life to determine how long the filter can be used when oil aerosols are present.

Respirator

Filters for Non-powered Air-purifying Respirators

New

Classification System

Old

Classification System

Filter

Class/Efficiency

Resistance

to Oil

Filter

Class/Efficiency

Resistance

to Oil

95

(95% efficient

at 0.3 um)

Superior to old dust/mist and old dust/mist/fume in efficiency

Three

Types

N

= Not Resistant to oil

R = Resistant to oil

P = Oil Proof

Dust/Mist

Dust/Mist/Fume

No standard

or classification

99

(99%

efficient at 0.3 um)

Three

Types

N

= Not Resistant to oil

R = Resistant to oil

P = Oil Proof

There

was no filter in this range

There

was no filter in this range

100*

(99.97%

efficient

at 0.3 um)

Same as HEPA

*Only

P100 can be colored magenta/purple

Three

Types

N

= Not Resistant to oil

R = Resistant to oil

P = Oil Proof

HEPA**

(99.97% Efficient

at 0.3 µm)

**Colored

magenta/purple

No standard

or classification

|

|

||||

|

|

|||

|

|

|

|

|

|

|

(95% efficient at 0.3 um) Superior to old dust/mist and old dust/mist/fume in efficiency |

R = Resistant to oil P = Oil Proof |

|

|

|

|

|

R = Resistant to oil P = Oil Proof |

|

|

|

|

at 0.3 um) Same as HEPA

|

R = Resistant to oil P = Oil Proof |

(99.97% Efficient at 0.3 µm)

|

|

|

Filtering

Face Piece

Filtering

Face Piece

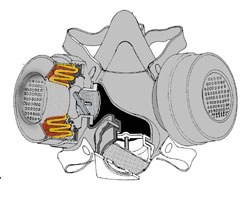

Powered

Air-Purifying Respirator(PAPR)

Powered

Air-Purifying Respirator(PAPR)

Guidelines for typical activities

The following table

lists some common construction activities and suggests respiratory protection

that should provide adequate protection in most circumstances. In several

cases more than one recommendation is given. Every situation is different.

Factors such as the amount of ventilation, degree of enclosure, duration

of exposure, specific work activity, other contaminants in the area, and

user characteristics can all affect respirator selection. Please contact

your respirator manufacturer or CSAO if you are unsure about the selection

of a respirator for a specific task.

View Chart 1(Respirator Selection Guide for Common Construction Activities)

View Chart 2 (Respirator Selection Guide for Common Construction Activities)