Summary Statement

One-page summaries of over 100 NIOSH-supported construction safety and health research projects in 2002.

2003

SUMMARY OF BLOOD LEAD MONITORING EVALUATION PROJECT

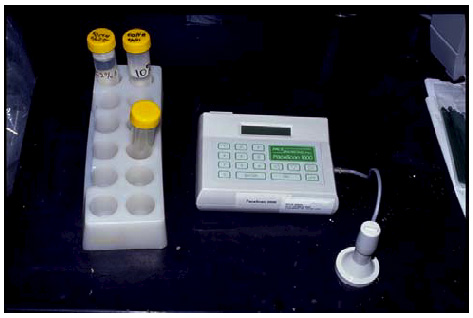

ESA's LeadCare ASV instrument

RESEARCHER: Lauralynn Taylor

AFFILIATION:

Division of Surveillance, Hazard Evaluations, and Field Studies

National Institute for Occupational Safety and Health (513) 841-4571

PURPOSE: Validate an anodic stripping voltammetry instrument that analyzes capillary and venous blood lead levels rapidly in the field.

RESEARCH SUMMARY: It is estimated that more than 30,000 individuals in the United States have work-related blood lead levels above 25 µg/dL. OSHA, EPA, and HUD require exposure monitoring for both blood lead and environmental lead levels. Currently, the blood monitoring methods require a venipuncture blood draw and shipment to an off-site laboratory for analysis.

An anodic stripping voltammetry instrument has been developed by ESA, Inc., Chelmsford, MA, in conjunction with CDC. This instrument provides a prompt, cost-effective technique to monitor lead exposures for pediatric screening. Although this instrument has only been used with children whose blood lead levels are significantly lower than in exposed adults, its capability to analyze blood quickly on-site makes it potentially valuable to occupational health professionals during on-site investigations, particularly with highly transient workers such those in construction. We will compare instrument results with split samples analyzed according to CDC's Whole Blood Method 1080C from adult populations exposed to high lead levels. The practicality and cost-effectiveness of using this instrument in the workplace will be assessed and its precision estimated.

A second objective of this project is to collect samples from earlobe capillaries and determine whether these samples can be used to monitor blood lead levels. This sampling and analytical technique is less invasive and could provide quicker results than current methods, guiding efforts to reduce lead exposures rapidly.

KEYWORDS: Lead, biomarkers, exposure assessment

RECENT CITATIONS:

Taylor, L., R.L. Jones, L. Kwan, J.A. Deddens, K.A. Ashley, and W.T. Sanderson. 2001. Evaluation of a portable blood lead analyzer with occupationally exposed populations. American Journal of Industrial Medicine, v. 40, no. 3, pp. 54-362.

Taylor, L., R.L. Jones, L. Kwan, J.A. Deddens, K.A. Ashley, and W.T. Sanderson. 2000. Blood lead monitoring technologies. Presentation at Council and State Territory Epidemiologists Conference, New Orleans, LA, June 2000.

Taylor, L., R.L. Jones, L. Kwan, J.A. Deddens, K.A. Ashley, and W.T. Sanderson. 2000. Blood lead monitoring: An evaluation of a rapid blood lead analyzer. Presentation at American Industrial Hygiene Conference, Orlando, FL, May 2000.

LOCAL POSITIONING SYSTEM FOR EXPOSURE ASSESSMENT AND CONTROL

RESEARCHER: Jennifer Hornsby-Myers

AFFILIATION:

Health Effects Laboratory Division

National Institute for Occupational Safety and Health (304) 285-6358

PURPOSE: Design and develop prototype personal-location units that can be used in conjunction with appropriate monitoring devices both indoors and outdoors to assess safety and health hazards in the workplace.

RESEARCH SUMMARY: Workers in many occupations move about frequently during a typical workday. Certain workers, such as agricultural and construction workers, are particularly mobile. By linking a worker's location throughout the workday to real-time monitors of hazardous materials, local positioning system (LPS) units with data processing capabilities could identify and document where to focus exposure analyses and control efforts. Post-processing of LPS data may enable researchers, regulatory inspectors, and industry safety and health personnel to map the location, distribution, and intensity of a hazardous material. In addition, LPS units may allow researchers to explore new means of detecting, analyzing, and controlling safety and health hazards.

An outdoor backpack prototype was reduced to a hand-held prototype. This smaller prototype will be field tested with real-time exposure sensors (dust, noise, temperature, and a gas monitor) to determine its performance. LPS units will use industry-standard connectors to input data from portable exposure monitors. Work conducted in collaboration with the U.S. Coast Guard Academy's Center for Advanced Studies has shown direct-sequence spread-spectrum technology to be feasible for indoor positioning when using military frequencies. The NIOSH LPS design will allow easier set-up at research sites than do existing monitors and will allow the device to be used on unlicensed civilian frequencies. The indoor LPS should provide information on indoor air quality and noise levels.

KEYWORDS: Control technology, exposure assessment, hazards

RECENT CITATIONS:

Hornsby-Myers, J.L., L. Lee, and M. Flemmer. 2002. Field testing of local positioning system. Poster presentation at Salt Fork X, Mineral Wells, WV.

SCREENING METHODS FOR AIRBORNE METALS IN CONSTRUCTION

RESEARCHER: Kevin Ashley

AFFILIATION:

Division of Applied Research and Technology

National Institute for Occupational Safety and Health (513) 841-4402

PURPOSE: Provide methods and technologies for on-site screening of metals in workplace samples to allow worker exposure and the effectiveness of control measures to be assessed in a timely manner.

RESEARCH SUMMARY: Several million workers in the United States are exposed to toxic metals on the job. Traditional exposure monitoring techniques requiring laboratory analysis are not always useful in the construction industry because results may not be available quickly enough to avoid overexposures or prolonged shutdown periods. Therefore, new methods for monitoring metals on-site, including metal species not previously investigated, need to be developed and evaluated so that information about worker exposures can be provided rapidly or, in some cases, even before work begins.

Although several portable analysis technologies and methods for measuring concentrations of airborne metals have been developed recently, they have not seen wide use in the workplace. This may be due to expense, complexity, poor limits of detection or accuracy relative to laboratory-based analysis, and nonacceptance by regulatory agencies. For example, portable anodic stripping voltammetry (ASV) and portable x-ray fluorescence (XRF) have recently been field-tested at construction and mining sites in collaborative work with the Spokane Research Laboratory; the Health Effects Laboratory Division; and the Division of Surveillance, Hazard Evaluations, and Field Studies. Other emerging technologies, such as laser- and spark-induced breakdown spectroscopy, show strong potential to provide real-time or near-real-time readings of airborne metal concentrations, but need to be fully developed and evaluated if they are to be considered for use as portable screening technologies for workplace applications. These collaborations will afford more comprehensive development and assessments of the performance and cost-effectiveness of portable technology in many workplace settings.

The refinement and careful testing of existing field-portable methods, along with the development of new ones, could herald a generation of simplified instruments and tools capable of providing rugged, accurate, and cost-effective screening for numerous airborne metals in the workplace on a near-real-time basis.

PATENT: Esswein, E., M. Boeniger, and K. Ashley. 2001. Handwipe disclosing method for the presence of lead. U.S. Patent 6,248,593.

KEYWORDS: Screening methods, exposure assessment

RECENT CITATIONS:

Sussell, A., and K. Ashley. 2002. Field measurement of lead in work-place air and paint chip samples by ultrasonic extraction and portable anodic stripping voltammetry. Journal of Environmental Monitoring, v. 4, pp. 156-161.

Song, R., P.C. Schlecht, and K. Ashley. 2001. Field screening test methods: Performance criteria and performance characteristics. Journal of Hazardous Materials, v. 83, pp. 29-39.

Ashley, K., T.J. Wise, W. Mercado, and D.B. Parry. 2001. Ultrasonic extraction and field-portable anodic stripping voltammetric measurement of lead in dust wipe samples. Journal of Hazardous Materials, v. 83, pp. 41-50.

Marlow, D., J. Wang, T. J. Wise, and K. Ashley. 2000. Field test of a port-able method for the determination of hexavalent chromium in workplace air. American Laboratory, v. 32, no. 15, pp. 26-28.

ENVIRONMENTAL TRACTOR CAB SYSTEM INTEGRITY

RESEARCHER: Ernest Moyer

AFFILIATION:

Division of Respiratory Disease Studies

National Institute for Occupational Safety and Health (304) 285-5962

PURPOSE: Evaluate aerosol exposure reduction resulting from the use of enclosed cabs.

RESEARCH SUMMARY: Construction workers, as well as workers in numerous other occupations such as mining, farming, and trucking, depend on enclosed environmental cabs to protect them from hazardous aerosols while they are operating equipment. These aerosols are often of unknown concentration and toxicity. This project will provide a critical link in the process of determining the cause(s) of hazardous exposure within enclosed cabs on equipment such as bulldozers, front-end loaders, grapplers, graders, haulage trucks, and tractor cabs.

Particulate filter efficiency has been tested in the laboratory. Now, aerosol particle counters are being evaluated to determine their ability to monitor total cab integrity and will be used in the field to identify leaks in environmental cabs. Equipment manufacturers, equipment operators, and NIOSH researchers will collaborate to measure the degree to which aerosols can penetrate environmental enclosures under real-world conditions. All phases, from manufacturing and design, audits, and routine maintenance, will be studied. Appropriate aerosol test methodology will be incorporated into a total cab performance program.

KEYWORDS: Control technology, exposure assessment, heavy equipment cabs, aerosol filtration, respiratory disease

RECENT CITATIONS:

Heitbrink, W.A., E.S. Moyer, P.A. Jensen, D.S. Watkins, and S.B. Martin. (2002. In press.) Envi-ronmental agricultural tractor cab filter efficiency and field evaluation. American Industrial Hygiene Association Journal.

AEROSOL SAMPLER DEVELOPMENT

RESEARCHER: Paul Baron

AFFILIATION:

Division of Applied Research and Technology

National Institute for Occupational Safety and Health (513) 841-4278

PURPOSE: Develop and evaluate more accurate fiber and dust samplers.

RESEARCH SUMMARY: Workers are exposed to dust that can include lead, chromium, and silica at virtually every construction site. Road construction and well drilling can create large quantities of silica-containing dust. Sanding and woodworking produce high concentrations of wood dust. Asbestos is still being removed from many facilities, and other fibers, such as refractory ceramic fibers, are still being used commercially.

Improved dust samplers are needed to assess total and respirable dust exposures for personal monitoring and dust control system evaluations. A collaboration between researchers at NIOSH's Division of Applied Research and Technology (DART) and the Health Effects Laboratory Division (HELD) has resulted in a new type of fiber length classifier that helps to analyze the in vitro toxicity of fibers as a function of fiber length. Preliminary tests of several options for a fiber sampler specific for the thoracic portion of aerosols have been carried out. The thoracic sampler will replace the current sampler, which has problems with sample uniformity and losses in the inlet.

Improvements are also needed in ways to determine sampler efficiency so that improvements can be made in determining overall sampler accuracy. Current techniques for evaluating large particles with personal samplers are slow and expensive. A wind tunnel was constructed that can measure airflow around the human body with a laser Doppler velocimeter (LDV). These measurements will be complemented with a particle-imaging velocimeter (PIV) that measures the flow field more rapidly and efficiently. A system that can generate a wide range of aerosol sizes has also been constructed to measure the sampling efficiency of aerosol samplers mounted on a body. Aerosol concentrations are measured at various locations around a manikin with either LDV or PIV systems (which count particles) or with isokinetic samplers (which measure particle concentrations at various distances from a body).

Velocity measurements were taken around the chest and "breathing zone" of a life-size manikin, as well as around a simplified manikin and freestanding samplers. The data are being examined by HELD to develop and validate computational fluid dynamics models of airflow around the samplers on the manikin. The combination of flow field measurements and calculations of particle concentrations will allow less expensive, more direct, and more rapid determinations of sampler inlet efficiency.

KEYWORDS: Aerosols, respiratory disease, sampling methods

CONTROL OF EXPOSURES DURING CONSTRUCTION

RESEARCHER: Leo M. Blade

AFFILIATION:

Division of Applied Research and Technology

National Institute for Occupational Safety and Health (513) 841-4549

PURPOSE: Investigate the availability of engineering controls for identified construction processes. Assist equipment manufacturers in the design of engineering solutions to reduce exposure to occupational hazards, as well as help employers implement these designs.

RESEARCH SUMMARY: Researchers will assess the efficacy of exist-ing measures to reduce occupational health hazards associated specifically with abrasive blasting, drywall finishing, and asphalt paving and roofing. Such measures include engineering controls and substitute materials and processes.

- An estimated 150,000 workers are employed in abrasive blasting, where they are exposed to a variety of airborne contaminants that may place them at risk of pulmonary disorders and other work-related illnesses. Existing tech-nologies and methods, such as wet blasting, high-pressure water blasting, and the use of personal protective equipment, will be evaluated at active operations to evaluate performance efficacy and worker acceptance. Airborne contaminant exposure levels and environmental emissions controls will also be evaluated. The evaluation will include direct costs of equipment, materials, and environmental controls, and indirect costs affecting productivity associat-ed with each control measure evaluated. When appropriate and feasible, con-trol modifications and optimizations may be recommended. Finally, industry and equipment manufacturing partners receptive to assisting in the development and implementation of the most promising exposure-control measures will be pursued.

- Drywall finishing generates compounds that may contain crystalline silica, and previous research has documented overexposures to total airborne particu-lates among drywall finishers. Although this research has identified effective dust control devices for drywall sanding, few drywall finishers routinely use them. NIOSH has a cooperative agreement with the United Labor Agency, Cleveland, OH to address economic and other real or perceived barriers to existing and effective engineering measures for dust control.

- Much of the research to date has focused on the reduction of asphalt fumes associated with highway paving. Asphalt fumes are a known irritant to workers' mucous membranes and skin. Several research studies have suggested links to carcinogenic activity. OSHA recently listed asphalt fume exposures (roofing and paving) as one of 18 OSHA priorities, and the American Conference of Government Industrial Hygienists has proposed a more stringent standard for evaluating exposures to asphalt fumes. A Hazard Review document on asphalt fume exposure has been written.

RECENT CITATIONS:

National Institute for Occupational Safety and Health. 1999. Control of drywall sanding dust exposures. NIOSH Hazard Controls HC30. DHHS (NIOSH) Pub. 99-113.

Mead, K.R., R.L. Mickelsen, and T.E. Brumagin. 1999. Factory performance evaluations of engineering controls for asphalt paving equipment. American Industrial Hygiene Association Journal, v. 14, no. 8, pp. 565-573.

ECONOMIC ANALYSES OF ENGINEERING CONTROL INTERVENTIONS FOR DRYWALL SANDING CONSTRUCTION ACTIVITIES

RESEARCHER: Joseph Ventura

AFFILIATION: Painters Health and Safety Fund (440) 239-4575

PURPOSE: Identify the real and perceived obstacles to implementing engineering controls for reducing hazardous exposures to airborne particles among drywall finishing workers and evaluate a methodology for overcoming these barriers.

RESEARCH SUMMARY: Several studies have indicated that drywall finishers are exposed to high levels of total and respirable dust. This research is designed to identify barriers to implementing engineering controls, to train workers and contractors in engineering controls, and to identify and promote incentives to implement healthy work practices.

Jobs and work groups in the drywall industry using current practices and practices will be identified, after which study participants be selected. Next, participants will be interviewed to determine the real and perceived barriers to the use of engineering controls. Surveys will then be developed to determine the production costs of conventional practices. An efficacy study will compare engineering controls and conventional technology, and the economic costs associated with the use engineering controls will be determined. Further research will compare costs of the two technologies on the job.

Throughout this study, training for engineering control intervention will be provided. This project will further knowledge and methods of protecting workers from airborne exposures and encourage contractors and workers to adopt healthy work practices.

KEYWORDS: Dust, economic consequence, engineering controls

CONTROL OF SILICA EXPOSURE FROM HAND-HELD CONSTRUCTION TOOLS

RESEARCHER: Alan Echt

AFFILIATION:

Division of Applied Research and Technology

National Institute for Occupational Safety and Health (513) 841-4111

PURPOSE: Evaluate the effectiveness of several engineering controls in reducing exposure to respirable crystalline silica from selected construction tasks identified during a larger study of silica exposures and controls.

RESEARCH SUMMARY: There are three components to this project.

Tuck-pointing: Tuck-pointing involves the removal of old mortar with a high-speed grinder, which creates large amounts of brick and mortar dust containing silica. Two preliminary evaluations were conducted at construc-tion sites and two more at Bricklayers and Allied Craftworkers Union training facilities. Next, a laboratory study was conducted at the International Masonry Institute, Ft. Ritchie, MD, to determine the ventilation parameters required to control the dust generated during tuck-pointing and brick cutting. Finally, a field study was conducted to verify the effectiveness of the laboratory findings for tuck-pointing ventilation.

Ready-mix concrete truck cleaning: Currently, workers are required to enter the interior of a mixing drum and use a jackhammer to remove cured concrete, generating a cloud of silica-containing dust. NIOSH researchers developed two engineering control options for jackhammers to reduce concentrations of airborne dust produced during this task: a local exhaust ventilation shroud and a water spray attachment. To test the effectiveness of the controls, a jack-hammer was retrofitted with the ventilation shroud and tested at a ready-mix concrete plant. Local exhaust ventilation reduced worker exposure to respir-able crystalline silica by more than 50%, and local exhaust ventilation com-bined with general exhaust ventilation reduced exposures by more than 60%.

Concrete grinding: When construction workers use grinders to smooth poured concrete surfaces, they risk overexposure to respirable dust and crystalline silica. Hand-held grinders are used to finish surfaces after forms are stripped, while walk-behind grinders are used on floors. An evaluation of four local exhaust shrouds for use with hand-held grinders found that all four shrouds were equally effective and that all reduced dust by at least 90%. A field study of a vacuum cleaner and shroud system for hand-held grinders found that it controlled exposures within the range of protection provided by a half-mask respirator. Finally, a field study of a job-built control for a scabbler that utilized water to suppress dust found that it achieved an 80% reduction in exposures to respirable dust, and by inference, resulted in a similar reduction in exposures to respirable crystalline silica.

KEYWORDS: Silica, aerosols, power tools

RECENT CITATIONS:

Heitbrink, W.A., and D.S. Watkins. 2001. In-depth survey report: Con-trol technology for crystalline silica exposures in construction: The effect of exhaust flow rate upon the respirable dust emissions for tuck pointing operations and a preliminary evaluation of a ventilated tool for brick cutting, International Masonry Institute, Cascade, Maryland, March 20, 2000, through November 3, 2000. EPHB Report 247-18.

Almaguer, D., S. Shulman, and A. Echt. 2001. In-depth survey report: Control technology for ready-mix truck drum cleaning for Hilltop Basic Resources, Cincinnati, Ohio, Jan. 14, 1999, through Feb. 12, 1999. EPHB Report 247-19.

Echt, A., and W.K. Sieber. 2001. In-depth survey report: Control of silica exposures from hand tools in construction: Grinding concrete at Frank Messer and Sons Construction Company, Newport, Kentucky, February 21-22 and 26 and March 2 and 6, 2001. EPHB Report 247-15c.

EVALUATION OF DUST CONTROL TECHNOLOGIES IN CONSTRUCTION TASKS

RESEARCHER: Noah Seixas

AFFILIATION: University of Washington (206) 685-7189

PURPOSE: Evaluate commercially available but untested masonry tools to determine their effectiveness in reducing dust emissions.

RESEARCH SUMMARY: Elevated occupational exposures to crystalline silica dust can result from using concrete and stone during construction. In particular, masons and concrete finishers can be exposed to unsafe levels of silica dust during the operation of power grinding, drilling, and cutting tools. A series of semi-controlled experiments will be conducted to determine the effectiveness of water and localized ventilation control techniques in suppressing dust. Six different classes of hand-held masonry power tools will be tested. Further characterization of silica exposures during typical masonry activities will be done at a variety of construction sites to evaluate how less-than- ideal conditions affect tool performance and control dust. The identification of effective control strategies for reducing silica dust exposures will provide practical guidance to the masonry construction industry and reduce the possibility of occupational lung disease related to silica exposure in this industry.

KEYWORDS: Silica dust, power tools, masonry

ELECTRONIC SAFETY DEVICES FOR CONSTRUCTION WORKERS

RESEARCHER: Edward Coonly

AFFILIATION: ViTech Systems, Inc. (716) 689-4025

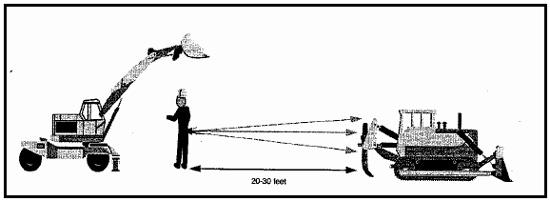

PURPOSE: Develop two electronic safety devices: (1) a moving hazard warning device to protect construction workers from being struck by or trapped between or beneath construction equipment and (2) an edge detector device to prevent worker falls from roofs and open-sided floors and platforms.

RESEARCH SUMMARY: The U.S. construction industry, with 6.0% of total employment, accounts for 8% of the total number of injuries and illnesses and 17% of the total number of fatalities. "Struck-by a moving object" and "caught in, under, or between-" type accidents account for 13.6% of the total number of accidents at construction worksites and cost $297 million annually. Falls through floor openings, shafts, decks, and open platforms account for 6.2% of the total number of construction accidents and cost about $227 million annually. At present, engineering controls to prevent these accidents do not exist.

To reduce these accidents, two devices that feature the use of ultrasonic sensors powered by small rechargeable batteries and controlled by microchips are being developed. Each safety device will be the size of a pager and built into the back of a toolbelt. The devices will warn a worker via an audible and/or vibration alarm whenever he or she is too close to approaching equipment or the edge of a roof or open-sided floor.

A prototype device for detecting floor openings and the edges of platforms has been developed. The batteries to power the device for one full work-week of 50 hours are still being investigated. Worker acceptability will be tested after a final design of the device is produced. A prototype of the moving hazard warning device, which will warn a construction worker if a heavy equipment is approaching from behind, is currently being tested in both the laboratory and the field. Limitations in the distance over which the ultrasonic sensors can detect moving equipment has been a major factor impeding the progress on the device. It may be necessary to customize the ultrasonic sensor. However, if the sensor fails to detect an object at an adequate distance under all weather conditions, we may evaluate the use of radio-frequency sensors.

PATENT: A patent application is in process.

KEYWORDS: Falls, "struck-by" accidents, safety devices

A DEVICE FOR ELIMINATING ELECTROCUTIONS BY MOBILE CRANES

RESEARCHER: Satish Mohan

AFFILIATION: ViTech Systems, Inc. (716) 689-4025

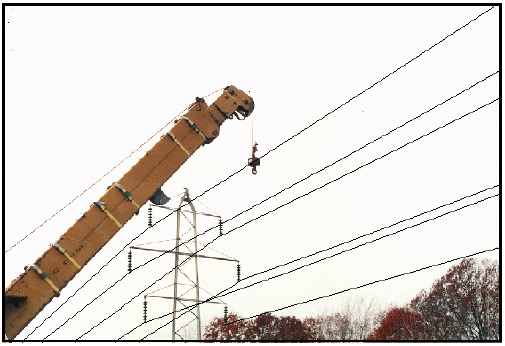

PURPOSE: Develop and field-test an electronic sensor system that can detect voltage intensity of overhead high-voltage powerlines and their distance from mobile cranes.

RESEARCH SUMMARY: In 1981, a year for which a complete data set is available, approximately 2,300 lost workdays, 115 fatalities, and 200 permanent total disabilities resulted when a mobile crane came into contact with a powerline. Forty-seven workers were killed in 1991 when scaffolds composed of metal or other conductive materials came into contact with powerlines. On average, seven workers are electrocuted every year in aerial lifts during tree trimming. The cost of these accidents is estimated at $259 million.

In this project, researchers will develop a sensor system that will warn a crane operator when the crane boom gets too close to a powerline. If the boom gets dangerously close, the system will trigger a loud alarm and a flashing light to warn the crane operator and those working in the vicinity of the crane. The alarm system will be designed as a number of sensors attached to the crane boom. These sensors will be connected to each other by a powered sensor bus and then to a microprocessor located in the operator's cabin. A second smaller system using a similar design will be developed for conductive scaffolds, aerial man-lifts, boom trucks, and other self-propelled machinery that could make physical contact with a powerline.

A prototype has been developed and tested on 4-kV, three-phase powerlines. The system measures electric fields precisely and can estimate both voltage and the distance of powerlines from the crane. Operating Engineers Local 17 and an electric utility company are cooperating in this work. The final version will include a video display terminal within the viewing area of the operator that will show the crane boom and powerlines in the vicinity of the crane.

PATENT: A patent application is in process.

KEYWORDS: Crane safety, crane electrocutions

FIELD STUDIES WITH INNOVATIVE SAFE EXCAVATION TECHNOLOGIES

RESEARCHER: Leonhard Bernold

AFFILIATION: North Carolina State University (919) 515-3677

PURPOSE: Evaluate new excavation technologies that promise to reduce radically several hazards related to backhoe excavation during construction.

RESEARCH SUMMARY: Previous research successfully demonstrated the feasibility and applicability of safe excavation and pipe-laying. This research "ruggedized" prototype technologies and demonstrated each as full-scale field experiments at actual construction sites using construction crews. From the lessons learned, new questions and further research topics have arisen. To achieve these goals, the following specific aims will be pursued.

- Extend the capabilities of the excavator-mounted, buried utility detection system (EM-BUDS). Currently this device can locate metallic pipes and powerlines; what is needed is a device that can locate plastic and concrete pipe.

- Address questions raised as to whether the pipe manipulator (PIPEMAN) can be used to place bedding remotely.

- Design and fabricate a smaller version of PIPEMAN (PIPEMAN, Jr.) that can lay smaller-diameter polyvinyl and steel pipes. Investigate issues regarding joints in these types of pipes, which have very different requirements than do concrete pipes.

- Integrate the expanded EM-BUDS and PIPEMAN, Jr.

- Improve the human-machine interfaces of EM-BUDS, PIPEMAN, and PIPEMAN, Jr.

- Demonstrate technologies at field sites.

Back to Contents