Summary Statement

Article highlighting how cheap portable Local Exhaust Ventilation units can reduce exposure to welding fumes.

1997

Welding fumes cause short-term illness, like metal fume fever. They can also cause deadly diseases, like lung cancer or Parkinson's disease (see pg. 11). The good news is that portable local-exhaust ventilation (LEV) for welding is available. The bad news is such equipment is not used much in construction.

As part of the Engineering and Work Practice Controls Work Group, the National Institute for Occupational Safety and Health (NIOSH) and CPWR – Center for Construction Research and Training (CPWR), have evaluated how well LEV units protect against welding fumes. The Controls Work Group since 1993 has been evaluating technologies and work practices to limit health hazards in construction. Along with, CPWR and NIOSH, the group includes experts from other organizations.In 1996, NIOSH engineers looked at 2 portable LEV units in a controlled setting with the help of the Boilermakers' Union. At the same time, CPWR and members of the Plumbers and Pipefitters' Union evaluated the LEV units in the field in California, Oregon, and Washington state. NIOSH measured fumes produced during stainless steel stick welding in a 20-foot-wide tank that was missing more than half its roof. In the tank, the 2 units cut worker exposures to welding fumes, but not always below permissible exposure limits (PELs) set by OSHA. OSHA has no PEL for welding fumes, but has them for total particulates, chromium, nickel, and other metals. In many cases, the OSHA objectives for the metals are too lax, based on 25-year-old information. The American Conference of Governmental Industrial Hygienists' (ACGIH) recommended exposure limit for welding fumes is 5 mg/m3.

Without LEV, total welding fume concentrations ranged from 2 to 60 milligrams per cubic meter (mg/m3) of air. Ventilation cut the fumes to 3 to 13 mg/m3. Even with ventilation, manganese and hexavalent chromium exceeded ACGIH limits, nickel exceeded limits set by NIOSH, and arsenic exceeded OSHA PELs. Manganese can cause Parkinson's disease. Chromium can cause cancer, sinus problems, and a perforated septum ("holes" in the nose). Nickel can cause asthma and cancer. The ventilation was less effective outdoors, because breezes make it hard to "capture" fumes.

CPWR measured fumes where pipefitters used the LEV units or natural ventilation — an open window or work outdoors. Fumes were measured around pipefitters welding carbon or mild steel and using many welding processes. The average exposure for 56 samples collected with only natural ventilation was 5 mg/m3.Average exposures among the 7 samples using the LEVs were 2 mg/m3 — less than half the ACGIH limit.

The University of North Carolina analyzed 200 CPWR measurements from 1995-96 and found t

hat workers who used any mechanical ventilation (including the

LEVs) had about 30% lower exposures to total fumes than their coworkers.

hat workers who used any mechanical ventilation (including the

LEVs) had about 30% lower exposures to total fumes than their coworkers.

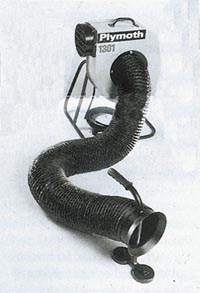

The equipment cut fumes and, thus, the risk of illness. And, the cheapest and lightest unit cut the fumes most. The unit is a simple portable fan with an accordion hose and magnetic foot on the nozzle; the foot holds the hood to steel (see picture).

Still, engineering and work practice controls for welding fumes need to be improved. For instance, LEVs should be lighter; they weigh about 45 pounds.

To follow up, the Building and Construction Trades Department has set up a welding fumes subcommittee to identify ways to protect welders. Also, Mount Sinai School of Medicine and CPWR will study "low-fume" welding rods and do more measurements of workers using the low-cost LEV that was the best of the units studied.

For more information, call Marjorie Wallace (NIOSH) at 513-841-4221 or Pam Susi (CPWR) at 301-578-8500. OSHA has a standard for ventilation and protection in welding (CFR1926.353).

And CPWR has a new hazard alert on welding fumes and gases. See page 9.

This local-exhaust ventilation unit made by PlymoVent Corp.of Edison, N.J., cut welding fumes most during field tests of portable units in 1996