Summary Statement

An in-depth training program for new employees at the World Trade Center Site, covering topics such as PPE wear, hazards of the site and emergency procedures.

| This program was developed by CPWR – Center for Construction Research and Training, with support from the National Institute of Environmental Health Sciences, in cooperation with participating Building Trades unions, site employers, the New York City Department of Design & Construction, and OSHA. |

- Site Safety

Structure

- Site Layout

Map

- Site-wide Work

Rules

- Contractor/Service-Specific

Work Rules

- Specific Site

Safety Issues & Controls

- Field Orientation

- Instructor

Introductions

- Joint Safety

& Health Committee

- Joint Site Inspections

- Working Together

for a Safer Job

- Purpose: To

advise on ES&H issues

- Membership:

- Tri-chairs:

NYC BCTD, BTEA, NYC DDC

- Prime Contractor

representatives – 4

- General

Contractors Association – 1

- Site Union

representatives – 6

- Tri-chairs:

NYC BCTD, BTEA, NYC DDC

- Badges &

Security – Entry & Exit

- Traffic Lanes

– 10 mph Maximum Speed!

- First Aid Stations

- Site Evacuation

Routes

- PPE zones

- Eyewash &

Showers

212-747-9193

Contractor/Agency Zone Map

- Site Description

& Project Expectations

- Location of

written safety programs

- Compressed gas

storage areas

- Subcontractor

activities

- PPE use zones

- Fuel depot and equipment refueling

General Site

Policies

- Site ES&H

program

- Labor-Management

Partnership for Safety

- Disciplinary

Warning Policy for Safety

- Drug &

Alcohol Policy

- Non-Discrimination

Policy

- Roles of Firefighters, Police & Construction

- Dust Control

& Fire Suppression

- Traffic Rules

- 100% Fall Protection

Above 6 feet

- 100% PPE Compliance

on Site

- Injury &

Incident Reporting

- Exit the site

CLEAN

- Crime Scene

Activities & Human Remains

- Project SPEED

LIMIT 10 MPH !

- Stay clear

of traffic lanes

- Stay clear

of areas where you don’t belong

- Be alert for

backup alarms and vehicles

- Watch for overhead

debris& collapse hazards

- Use covered

and marked walkways

- Do not walk

under live loads

- Respirators

(in defined zones)

- Hard hats

- Safety glasses

with side shields or goggles

- Long pants,

long sleeve work shirts, and coveralls

- High Visibility

Clothing/Reflective Vests

- Steel-toed,

heavy duty work shoes

- Debris Area

or Where Debris is Moved

- Half-face

respirator with combination P100 filter/acid gas/organic vapor

cartridge

- Half-face

respirator with combination P100 filter/acid gas/organic vapor

cartridge

- Dusty areas

within restricted zone/marina

- Half face

respirator with HEPA filter (P100, N95 or equivalent)

- Half face

respirator with HEPA filter (P100, N95 or equivalent)

- Other areas

with dust or smoke

- Dust mask

(P100 or N95 or equivalent)

- Dust mask

(P100 or N95 or equivalent)

- Hazard assessment

to determine need for PPE

- Medical Clearance

for PPE Use

- PPE selection

and fitting

- Training

- When PPE

is needed

- What PPE

is needed

- Use and

limitations of PPE

- Care and

maintenance of PPE

- When PPE

is needed

- Report work-related injuries and illnesses, imminent danger situations, or other incidents to your supervisor & steward

- New or expanding

fires should be immediately reported to fire department

EMERGENCY Phone: 212-747-9193

- Work-related

injuries or illnesses

- Exposures to

hazardous substances above allowable exposure limits

- Electrical

shocks or arc flashes

- Near misses

- Crane, rigging,

or material handling accidents

- Property/vehicle/equipment

damage

- Unplanned fires

or explosions

- Spills or releases

to the environment

- Unexpected

contact or damage to utilities

- Discovery of

unknown or potentially hazardous debris, containers or other materials

- You face unsafe

conditions not previously addressed

- You face an

imminent danger situation

- The scope of

work changes from the safety briefing

- You find bodies

or body parts

- You find unknown

or potentially hazardous objects or materials

WTC

Ground Zero Hazards

WTC

Ground Zero Hazards- Safety hazards

- Chemical hazards

- Physical hazards

- Confined space

hazards

- Biological hazards

- Other hazards

- Falls from heights

- Collapses

- Struck by/against

and caught in/between

- Fires and Burn

Hazards

100% fall protection when working more than 6 feet above a lower surface

Types of Fall

Protection

- Guardrails

- Around

excavations, holes, building edges, and wherever else possible.

- On aerial

lifts, crane manbaskets, scaffolds

- Around

excavations, holes, building edges, and wherever else possible.

- Personal fall

protection systems

- Fall arrest

– stops falls

- Fall restraint

– prevents falls

- Fall arrest

– stops falls

- Harness

- Lanyard

- Vertical or

horizontal lifeline

- Adequate anchorage

point

- Always inspect

before use

- Aerial lifts

(JLG, Genie, etc.)

- Must wear

harness/lanyard as fall restraint

- Secure

lanyard ONLY to approved lift anchor

- Make sure

railings, doors, chains are in place

- Do not climb

on rails or use ladders, boxes, etc.

- Must wear

harness/lanyard as fall restraint

- Crane manbaskets

- Must wear

harness/lanyard as fall restraint

- Secure

lanyard to independent anchor on crane, NOT crane basket

- Must wear

harness/lanyard as fall restraint

- Competent person

must check excavation sites at start of each shift and as needed

- Surface collapses

- Comply with

approved demolition plan before removing girders, large chunks

of concrete, etc.

- Comply with

approved demolition plan before removing girders, large chunks

of concrete, etc.

- Trench collapses

(cave-ins)

- Have proper

access and way to escape

- Use proper

protective devices

(benching, shoring, sloping, trench boxes)

- Have proper

access and way to escape

- Make sure you

are trained in use of model of equipment you will be working on

- Inspect equipment

at start of shift

- Make sure surface

is stable

- Don’t

exceed rated load limits

- Don’t

exceed boom extension limits

- Watch for struck

by/against accidents

- Follow all manufacturers

directions

- Stand clear

of operating equipment and vehicles

- Wear high visibility/reflective

clothing!

- Be alert for

backup alarms on vehicles

- Avoid entering

crane swing radius

- Use tag lines

when lifting loads

- Use spotters

during lifting operations

- Falling debris

- Barricade

off falling object hazard areas

- Wear hard

hats at all times

- Barricade

off falling object hazard areas

- Sharp objects

in debris

- Work gloves

- Protective

clothing

- Work gloves

- Be alert for

hot steel, hot debris and smoke

- Fires should

be immediately reported to fire department

- Hot Work Procedures

- Fuel & compressed gas cylinders

Fire or Emergency

CALL: 212-747-9193

- Separate oxygen

cylinders from fuel cylinders by at least 20 feet, unless protected

by fire wall

- Store acetylene

cylinders upright

- Protect against

falling and high temperature

- Protect against

falling objects

- Do not store

in unvented areas

- Cap & secure

cylinders

- Refuel vehicles

ONLY in designated area

- Refueling areas

must be at least 50 feet from other operations and storm drains

- Fuel storage

and filling areas are marked “No Smoking or Open Flames”

- Locate disconnect

switches for refueling equipment away from refueling areas

- Spill control

and cleanup materials available

- An ABC fire

extinguisher shall be located 25-75 feet from refueling operations

- Allow portable

equipment time to cool down before refueling

- Shut down spark-producing

equipment

- Dispensing

nozzles must have automatic shutoff and not have “latch open”

device

- NO plastic

containers! Use only properly labeled and approved containers

- Do not store

in direct sunlight

- Relieve pressure

buildup away from ignition sources (hot surfaces, sparks)

- Chemicals brought

on site

- Chemicals possibly

present in WTC debris and air

| Substance | Skin/Eye Contact | Inhalation | Ingestion |

| Diesel fuel | X | X | X |

| Acetylene gas | X | X | |

| Greases, oils, hydraulic fluids, cutting oils | X | X | X |

| Gasoline, petroleum distillates | X | X | X |

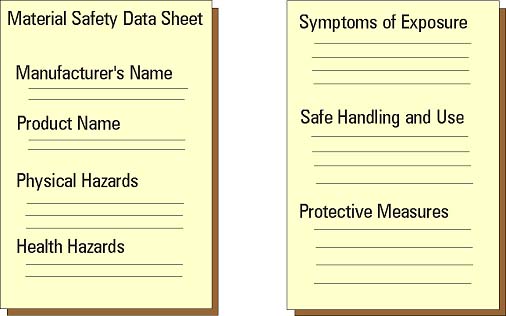

Material Safety Data Sheet Sample

You must be trained in how to read MSDSs

Chemicals Possibly Present in WTC Debris and Air

- Dusts

- asbestos,

crystalline silica, fiberglass dust, toxic metals (arsenic, lead,

chromium)

- asbestos,

crystalline silica, fiberglass dust, toxic metals (arsenic, lead,

chromium)

- Smoke

- particulates

- Benzene,

carbon monoxide, hydrogen chloride, hydrogen sulfide, PCBs, PAHs,

- particulates

- Others:

- exhaust

from vehicles and gas-powered tools

- Freon

- exhaust

from vehicles and gas-powered tools

- Prevent inhalation

- respirators

- respirators

- Prevent skin/eye

contact

- Safety

glasses with side shields or goggles

- Proper gloves

and protective clothing

- Safety

glasses with side shields or goggles

- Prevent ingestion

- NO eating,

drinking, smoking, chewing tobacco except in designated areas!

- NO eating,

drinking, smoking, chewing tobacco except in designated areas!

- Wash Hands &

Face

- Shower After

Work Where Available

- Change into

Street Clothes After Work

- Store Street

Clothes in Clean Area

- Wash Work Clothes

Separate from Family’s

- Cold

- Heat

- Noise

- Electrical hazards

- Manual lifting

- Can cause frostbite,

hypothermia

- Contributing

factors:

- Damp, windy,

or wet weather

- Damp, windy,

or wet weather

- Prevention:

- Warm, dry

clothing

- Work breaks

in warm shelters

- Warm, dry

clothing

- Can cause heat

stress, heat exhaustion, heat stroke

- Contributing

factors:

- Temperature,

humidity, heavy work, continuous work,

- Fires, hot

surfaces

- Temperature,

humidity, heavy work, continuous work,

- Prevention:

- Proper

type of clothing

- Work breaks

in cool area

- Proper

type of clothing

- Can cause hearing

loss

- Action level

of 85 decibels triggers hearing conservation program

- Noise monitoring

- Worker protection

- Engineering

controls (quieter equipment)

- Administrative

controls (job rotation)

- Hearing

protection (ear plugs, ear muffs)

- Engineering

controls (quieter equipment)

- Hearing

tests

- Training

- Noise monitoring

Electrical Hazards

- Electrical shock

and electrocution

- Electrical

burns

- Arc flash burns

- Arc blast effects

- hearing

loss, pressure wave

- hearing

loss, pressure wave

- Falls

- Fire

- Watch for buried

power lines. Don’t assume they are de-energized.

- Keep all metal

ladders and other conductive objects away from live circuits/power

lines

- Make sure all

electrical outlets have GFCIs

- Use only hard

or extra-hard usage extension cords with 3 prongs

- Properly maintain

electrical cords & equip.

- Use only tools

and equipment labeled for wet or damp areas

- Make sure plugs

have 3 prongs or are double-insulated

- Inspect cords

for exposed wires, frayed, spliced or taped cords or other damage

- Tag defective equipment and remove from service

- Lock and tag

all energy sources of equipment you will work on

- Each person

working should install own lock

- Each person

working should install own lock

- Released stored

energy

- Before removing

locks after working on equipment, notify others in area and check

area

- Make sure you

are trained and know written Lockout/Tagout Program

- Can causes back

pain and injury

- Use proper lifting

techniques

- Use lifting

devices or get help for heavy loads

- Avoid bending

or twisting while lifting

- Hold loads

centered and close to the body

- Arrange

lifting tasks to keep load between knuckle height and shoulder

height

- Avoid repeated

one-handed lifting

- Rotate continuous lifting tasks

- Use lifting

devices or get help for heavy loads

Site ES&H Plan calls for each contractor to comply with 29 CFR 1910.146 (OSHA Permit-Required Confined Space Standard) and have a plan reviewed by DDC.

Confined Space Definition

Confined Space

- Large enough

for human entry

- Limited or restricted

entry or exit

- Not meant for

human occupancy

Confined Space Hazards

- Oxygen deficiency

- Other gases

crowd out oxygen

- Other gases

crowd out oxygen

- Toxic gases

- carbon monoxide

from fires & engines

- carbon monoxide

from fires & engines

- Collapses

- trench cave-ins,

underground collapses

- trench cave-ins,

underground collapses

Confined Space Safety

- Permits required

for all confined space entry

- Confined Space

Entry Program

- Measures

to prevent unauthorized entry

- Identification

of hazards and testing

- Safe entry

and rescue procedures

- Proper PPE,

equipment for testing, rescue, etc.

- Outside

attendant(s)

- Additional

specific training of all involved personnel

- Measures

to prevent unauthorized entry

- Animal bites

and insect stings

- Report animal

bites and stings to first aid station for evaluation and treatment

- Use mosquito

repellent during mosquito season

- Report bee/wasp

allergies to employer safety officer prior to working at WTC site

- Report animal

bites and stings to first aid station for evaluation and treatment

- Bird droppings

- May cause

illnesses if inhaled or accidentally eaten

- Respirators

and protective clothing may be needed in nearby buildings if significant

amounts are present

- May cause

illnesses if inhaled or accidentally eaten

- Post-Traumatic

Stress Disorders

- Night work

- Poor lighting

- Body rhythms

- Poor lighting

- Extended hours

- Fatigue

- Fatigue

- Exhaust/Carbon

Monoxide

- Contractor &

Trade Specific Training

- Specialty Training

is Available and Training Needs Should be Communicated through Union

Stewards to the Joint S&H Committee

- New hazards

may arise requiring additional training for all site workers.

Respiratory

Protection

Respiratory

ProtectionRespirators Types of Respirators on Site

- Half Face respirators

- Full Face Respirators

- Different brands

- P100

- filters

out toxic and nuisance particles

- Color:

Purple/Magenta

- filters

out toxic and nuisance particles

- Acid Gas and

Organic Vapor Combination Cartridge

- Filters

out vapors like benzene and solvents

- Filters

out sulfuric acid gas

- Color: Yellow

- Filters

out vapors like benzene and solvents

- Facial Hair

- Medical evaluation/examination

- Workers

must be evaluated and obtain medical clearance to make sure that

wearing a respirator will not present health risks for them individually

- Fit Testing

on brand, model, and size you will wear

- Qualitative

- Quantitative

- Workers

must be evaluated and obtain medical clearance to make sure that

wearing a respirator will not present health risks for them individually

- Training

- Inspection

- Clean

- Filters/Cartridges

- Valves

- Clean

- Fit Checks

- Positive

and Negative fit checks

- Positive

and Negative fit checks

- Cleaning and Storage

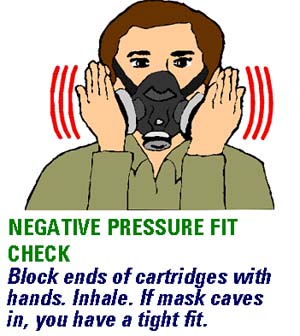

Negative Pressure Check

EVERY TIME You put it on!

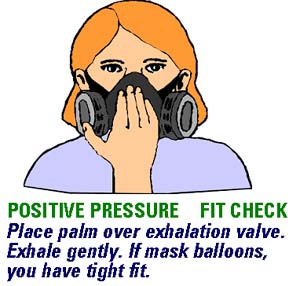

RespiratorsPositive pressure check

EVERY TIME You put it on!

Respirator Limitations

- Site respirators

filter air, they do not supply air, so they are useless in an oxygen

deficient atmosphere.

- Filters can

become clogged, being harder to breath through. Change regularly.

- Acid Gas/Organic

Vapor Cartridges can become saturated and useless. Cartridges should

be changed according the schedule in the Contractor’s Respiratory

Protection Program.

- If the respirators

doesn’t seem to fit, ask for a new brand or size and get refitted.

- If you feel

bad while wearing a respirator, ask about a new medical evaluation.

- If you have

any questions about respirators, ask for your employers’ program

administrator or written program.

Field Orientation

Follow the instructor back to the site for a visual review of key locations