Summary Statement

Describes a number of fatal accidents caused by the unexpected release of an excavator bucket from a quick coupling device on a hydraulic excavator and discusses actions that can be taken to avoid these accidents

| This Safety and Health Information Bulletin is not a standard or regulation, and it creates no new legal obligations. The Bulletin is advisory in nature, informational in content, and is intended to assist employers in providing a safe and healthful workplace. The Occupational Safety and Health Act requires employers to comply with hazard-specific safety and health standards. In addition, pursuant to Section 5(a)(1), the General Duty Clause of the Act, employers must provide their employees with a workplace free from recognized hazards likely to cause death or serious physical harm. Employers can be cited for violating the General Duty Clause if there is a recognized hazard and they do not take reasonable steps to prevent or abate the hazard. However, failure to implement any recommendations in this Safety and Health Information Bulletin is not, in itself, a violation of the General Duty Clause. Citations can only be based on standards, regulations, and the General Duty Clause. |

Following a fatal accident caused by the unexpected release of an excavator bucket from a quick coupling device on a hydraulic excavator, the Occupational Safety and Health Administration (OSHA) reviewed its Integrated Management Information System (IMIS) accident data. The accident data revealed 15 incidents since January 1998 involving the unanticipated release of excavator buckets from quick couplers on hydraulic excavators. Eight workers died in these incidents. OSHA urges employers using quick couplers to inspect their quick couplers and take appropriate measures to prevent unintended bucket releases, which can result in death or serious injuries.

Purpose

The purpose of this Safety and Health Information Bulletin (SHIB) is to:

- Alert employers and employees who use quick couplers on hydraulic excavators that connected attachments could unexpectedly release from the quick couplers if necessary corrective actions have not been taken;

- Explain how buckets and other attachments can be unintentionally released from quick couplers; and

- Detail actions to prevent such unintended releases.

The OSHA Madison, Wisconsin Area Office recently investigated a fatal accident where a backhoe bucket was released unexpectedly from a quick coupler. OSHA’s statistical database revealed fourteen additional incidents within the last six years involving the use of this type of equipment where excavator buckets unexpectedly released from quick couplers. Of the fifteen accidents reported by Federal and state OSHA offices, eight resulted in employee fatalities.

Accident Description

The accident prompting this Safety and Health Information Bulletin occurred at a site where a contractor was installing water mains and laterals. An excavation for a lateral had just been dug and an employee entered that lateral to prepare to install the pipe. The excavator operator changed buckets using a quick coupler on the hydraulic excavator. When the excavator was swung to continue digging on the main line, the bucket became detached from the quick coupler and rolled/slid into the lateral excavation, striking the employee and killing him. The investigation revealed that a locking pin had not been manually installed on this coupler to prevent accidental release of this attachment.

Quick Couplers

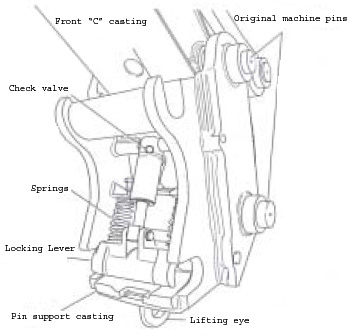

Quick couplers are after-market devices that have been used on hydraulic excavators for several years and have steadily increased in popularity. They enable contractors to quickly make attachment changes on hydraulic excavators. Most quick couplers have a lifting eye to use for lifting material. (Figure 1).

By removing the bucket (Figure 2), a large amount of weight is removed from the excavator and the lifting capacity of the excavator is increased by the weight of the bucket. Additionally, removal of the bucket improves the excavator operator’s line of vision during lifting.

Figure 1 |

Figure 2 |

|

|

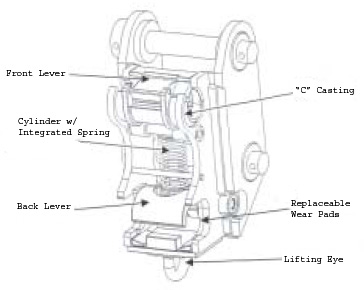

Many contractors like to use a large bucket to do the bulk of the digging and to then change to a smaller bucket for fine tuning and working in tight areas. The quick couplers also allow the operator to change from a bucket attachment to various other attachments. The unexpected releases of buckets are likely due in many cases to the failure of the quick couplers to be properly engaged and locked. (Figures 3 & 4).

Figure 3 |

|

Figure 4 |

|

Other Information

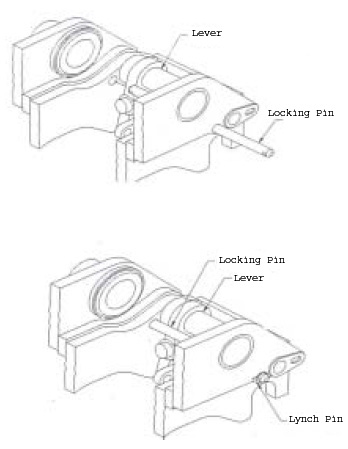

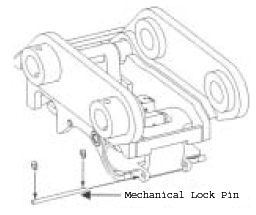

Quick couplers are made by various manufacturers. Manufacturers of quick couplers have recognized the hazard of the bucket or other attachments being unexpectedly released from the quick couplers and, in most cases, have provided users with a retrofit locking pin (Figures 5 & 6) which is manually inserted behind the front lever (stick pin) or rear lever (link pin) of the couplers to prevent unintended releases.

The National Institute for Occupational Safety and Health also has studied the hazards associated with hydraulic excavators and has issued DHHS Publication No. 2004-107 entitled, “Preventing Injuries When Working with Hydraulic Excavators and Backhoe Loaders”. This publication addresses the hazard of excavator buckets being unintentionally detached from a quick-disconnect mechanism.

Figure 5 |

|

Figure 6 |

|

Conclusions

Based upon experience, manufacturers have retrofitted existing quick couplers, designed new and improved quick coupler systems, and developed safe use and operating procedures. These corrective actions have significantly decreased the probability of a bucket or other attachment being unintentionally released from a quick coupler. However, unintended releases of buckets and other attachments from quick couplers continue as evidenced by the fatal accident in Madison, Wisconsin and the IMIS accident data. Unintended releases appear to continue because: not all employers/contractors who use quick couplers are aware of the hazard and the manufacturers’ corrective actions; some users fail to retrofit the quick coupler with locking pins; and some users have insufficient training on installation and testing procedures associated with the use of such couplers.

Safety Measures to Prevent Accidents

Employers using hydraulic excavators with quick coupling devices can protect employees from the unintended release of attachments by:

- Inspecting all quick couplers to determine if they are subject to unexpected release hazards. Determine whether a manually installed locking pin and installation procedures have been provided by the manufacturer.

- If necessary, obtain and install retrofits recommended by the manufacturer, including positive locking pins and other devices that need to be manually installed.

- Considering the use of newer models of quick couplers that have been specifically designed to prevent the unintended release of attachments.

- Following the manufacturer’s recommendations for maintenance and inspection of the quick coupler to prevent a malfunction of the quick coupler that could cause an unintended release of the attachments.

- Following the manufacturer’s installation procedures and recommendations on testing quick coupler and attachment connections every time an attachment is made.

- Training employees in: the proper use of quick couplers; making visual inspections; procedures for engaging attachments; and methods for testing connections.

- Requiring employees to use the proper procedures for engaging excavation attachments and incorporating the procedures into the company’s safety and health program.