CSAO Drywall Sanding: Dust exposure and ergonomics

Summary Statement

Reporting results of a study comparing the use of an electric shrouded ventilated rotary sander (SVRS) to that of a pole sander, measuring ergonomic differences and exposure to dust.

Winter 2004/2005

Health

Almost every construction project involves installation of drywall for interior walls. One step in drywall finishing is sanding the drywall compound.Currently, workers sand the compound manually using a handheld block or a long-handled pole (Figure 1) with a piece of sandpaper at the end of a swivel plate.

Stress

To create sufficient friction for sanding, the worker applies pressure to the manual sander. This results in stress on the back, arms, and wrist.

Dust

Sanding also generates high levels of dust including respirable silica. Inhaling this dust causes eye, nose, throat, and respiratory tract irritation, coughing, phlegm production, and breathing difficulties. Worse, it increases the risk of silicosis and lung cancer.

Sander

One way to control these health hazards is to use an electric shrouded ventilated rotary sander (SVRS).

The SVRS collects particulates by drawing air through the space between a) the outer circumference of the rotating abrasive pad and b) the inner surface of the shroud covering the abrasive pad. The dust then passes into a vacuum collection system equipped with a high-efficiency filter.

Study

Three partners undertook a study to document the potential ergonomic and hygiene benefits of using an SVRS to prevent musculoskeletal injuries and dustrelated illness. The partners were the International Brotherhood of Painters and Allied Trades District Council 46, the Interior Systems Contractors Association, and the Construction Safety Association of Ontario.

The study took place in a newly constructed home at the Interior Finishing Systems Training Centre in Toronto. We selected two very similar rooms—Aand B—to compare dust concentrations generated by conventional pole sanding with those generated by an SVRS. The total sanding area for room A was 256 ft2, and for room B, 286 ft2.

Eleven subjects participated in the study: seven journeymen and four apprentices from the Painters’ Union. While all participated in the dust measurement portion of the study, only ten participated in the ergonomic portion.

Each subject participated in two test runs for dust measurement:

1) using the pole sander in one room

2) using the SVRS in the other room.

Room and method of sanding were randomly selected.

To measure respirable dust concentrations, we used a TSI, model AM510, SidePak™ in conjunction with a Dorr-Oliver cyclone. The aerosol monitor is a small, directreading, data-logging unit.

While measuring respirable dust, we also measured muscle activity using electromyography (EMG). EMG signals were recorded by attaching surface electrodes to the skin above the following four muscles, selected to estimate muscle loads on the shoulders and forearm:

–– left upper trapezius

–– right upper trapezius

–– left flexor digitorum superficialis

–– right flexor digitorum superficialis.

Results: Respirable Dust

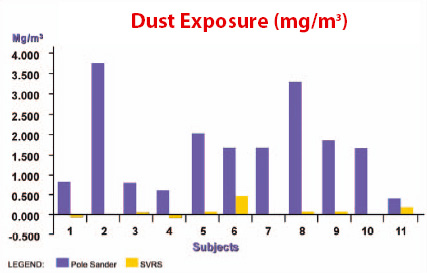

The research data indicate that the SVRS was very effective in capturing most of the respirable airborne dust.

Pole-sanding exposures ranged from 0.394 to 3.767 mg/m3 with a mean value of 1.686 mg/m3. SVRS exposures ranged from below background levels to 0.458 mg/m3 with a mean of 0.073 mg/m3. The difference between the two sanding methods was found to be highly significant (p<0.05) and represents a 96% reduction in respirable dust exposure.

This finding is consistent with other studies involving similar sanders.

From bulk samples, we detected an average concentration of 5% silica in the drywall compound used in this study—demonstrating that dust control is a continuing concern for drywall finishers.

Results: Ergonomics

Despite the large differences in weight between the SVRS (8 lbs) and the pole sander (2 lbs), working with the SVRS required significantly (p<0.05) less static load levels in the left and right trapezius muscles and the right forearm flexor. The median load level (dynamic work) involved significantly less muscle activity in the left and right trapezius muscles and in the right forearm flexor when a worker used the SVRS.

With the SVRS, there were significantly higher muscular rest durations for the right and left trapezius muscles and the left forearm flexor muscles than with the manual sander. Only the right trapezius muscle was found to have a significantly higher rest frequency with the SVRS.

With a manual pole sander, workers expend great muscular effort to create a high friction force between the sanding paper and the wall. Using the SVRS, however, requires comparatively little muscular effort because most of the sanding force is generated by the machine. In this case, the muscular effort observed in workers’ upper extremities served to support and guide the SVRS along the wall.

Amplitude domain analysissummaries of sanding using manual and machine methods |

||||||

SVRS |

Manual Pole Sanding |

P-Value |

||||

Mean |

SD |

Mean |

SD |

|||

Static level (p: 0.10) |

|

|

|

|

|

|

Left trapezius |

0.964 |

0.60 |

1.57 |

1.31 |

0.05* |

|

Right trapezius |

0.876 |

0.528 |

1.57 |

0.88 |

0.036* |

|

Left forearm flexor |

1.82 |

1.17 |

2.82 |

1.38 |

0.065 |

|

Right forearm flexor |

2.08 |

1.21 |

4.13 |

2.14 |

0.008* |

|

Median level (p: 0.50) |

|

|

|

|

|

|

Left trapezius |

7.05 |

3.03 |

8.79 |

4.21 |

0.024* |

|

Right trapezius |

7.32 |

2.94 |

10.62 |

4.48 |

0.009* |

|

Left forearm flexor |

7.6 |

3.95 |

10.18 |

4.91 |

0.10 |

|

Right forearm flexor |

9.74 |

3.70 |

13.07 |

4.98 |

0.034* |

|

Peak level (p: 0.90) |

|

|

|

|

|

|

Left trapezius |

21.16 |

7.49 |

23.38 |

8.03 |

0.287 |

|

Right trapezius |

24.94 |

10.02 |

25.83 |

8.88 |

0.556 |

|

Left forearm flexor |

23.90 |

11.13 |

22.83 |

12.87 |

0.786 |

|

Right forearm flexor |

23.53 |

6.48 |

26.94 |

8.86 |

0.279 |

|

* Significant at p<0.05 |

||||||

Comparing Muscle Use

Based on the ergonomic and

hygiene measures, we conclude

that the SVRS is an effective

method for drywall sanding and

recommend that the SVRS be used

to control drywall dust. The SVRS

has many advantages over pole

sanding.

Some advantages of the SVRS

- It significantly reduces exposure to drywall dust. Workers are much less likely to suffer adverse health effects.

- It greatly reduces the need for respiratory protection.

- It can significantly reduce cleanup time because it controls drywall dust so well.

- It is easy to use and unlikely to cause musculoskeletal problems.

- It is ideal for situations where creating dust is a problem— for example, renovations in occupied buildings, new construction when other trades are in the area, work in hospitals or medical facilities where patients must be protected, or work around dust-sensitive electronic equipment.

- The vacuum is not portable enough to be used in some circumstances—e.g., on a scaffold.

- The vacuum hose can create a tripping hazard.

- The round shape of the sanding head means it cannot fully sand corners.

- The vacuum and sander require electrical power that is not always available, especially on new construction sites.

Acknowledgements

This project was funded by a

research grant from the Workplace

Safety and Insurance Board

(Ontario). The authors are grateful

to the International Brotherhood

of Painters and Allied Trades

District Council 46 and the Interior

Finishing Systems Training Center

for their support.