Summary Statement

Alert issued by the Kier Group concerning an accident on one of their sites involving a 1999 model Skyjack type 8841 Scissor Lift MEWP that collapsed while being raised.

November 19, 2008

An incident recently occurred on one of our sites involving a 1999 model SKYJACK TYPE 8841 SCISSOR LIFT MEWP.

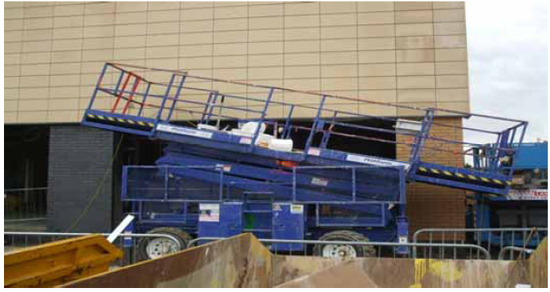

The MEWP was being raised from its base position with two men on board when a noise was heard and the machine was stopped. Those on board and a third workmate observing at ground level looked for any obstruction etc. Having found nothing they attempted to continue to raise the platform when a loud bang was heard, at the same time the front end collapsed into the position shown in Fig 1. Fortunately the working platform had been raised less than 2 meters at the time and although the operatives were pitched forward, they were not seriously hurt and were able to climb down to ground level.

Fig 1.

The rear end of the scissor packs’ scissor arms had sheared from their base pivot–pin connectors as shown in Fig 2, the close up shows one of these two failures.

Fig. 2

Initial examination identified oxidization, a suggestion of developing fatigue and final stress fractures as shown in Fig 3.

Fig. 3

This equipment has been recovered for detailed examination by Skyjack and the HSE.

The MEWP provider has advised that their engineers have since inspected all other examples of this make/model of scissor lift on their fleet, and report that no visual signs of any inherent fault were found.

Pending notification of any findings from Skyjack/HSE’s investigations, the following management action is to be taken on Kier Group sites:

- All examples of the SKYJACK 8841 model of MEWP are to be identified and taken out of service immediately, pending inspection by an engineer and written confirmation from the owner/supplier of being fit for use.

- All other scissor lifts on Kier Group sites are to be subject to an inspection, paying particular attention to scissor arm base connections prior to further use. Inspection being undertaken by the competent operator and findings recorded in the Project Register. Should there be any cause for concern identified the MEWP is to be taken out of service, pending a thorough examination to be arranged by the owner/supplier of the equipment.

- Attached is a Technical Service Advisory Note issued by Skyjack following this incident, which is to be referred to by those undertaking these inspections/examinations.

- Operators/users of scissor MEWPS are to be given a toolbox talk based on this alert, emphasizing the importance of:

- Operators diligently undertaking their daily checks/weekly inspections in accordance with manufacturer's instructions

- Users as well as operators remaining alert to any developing fault/deterioration

- If in any doubt, taking the machine out of service and reporting to management

John Morgan

Director Safety, Health & Environment

19th November 2008

Service Advisory Nov 2008

Skyjack Europe Technical Service

Unit 1, Maes-Y-Clawdd,

Maesbury Road Industrial Estate

Oswestry, Shropshire, SY10 8NN, UK,

Tel: +44 1691 676 235

Fax: +44 1691 676 239

Daily, Monthly and Annual inspections

In order to keep our customers informed Skyjack will post periodic reminders. We would like to draw your attention to the following:

It is important that operators and maintenance personnel carry out inspections as outlined in the applicable Skyjack operator and service manuals.

It is important that inspections are carried out on a regular basis, and adhered to as required by local regulations, (i.e. LOLER etc) and in accordance with the correct periods of inspection, which may be daily / weekly / monthly.

For example; all pins, weldments and pivot points are subject to high stress, and special consideration should be given to these particular areas as with any load bearing points.

Older machines in particular may have seized pins or joints, and if there is any doubt regarding the integrity of particular assemblies, they should be stripped and inspected further. Cracked paint, rust or loose retaining bolts can often indicate a problem which otherwise may not appear immediately obvious.

Our manuals are accessible online (www.skyjack.com) but if you are in any doubt contact your local Skyjack service department