Summary Statement

Information on steps cement masons can take to avoid falls, struck-by and caught-between accidents, including data on the frequency and risk of these types of injuries.

KEEPING CEMENT MASONS SAFE: PREVENTING FALLS, STRUCK BY and CAUGHT BETWEEN ACCIDENTS

GOALS OF THIS CLASS

- You will understand:

- The causes of falls, struck-by and caught-between accidents in cement work

- How they happen

- You will be able to:

- Reduce your risk of falls, struck by and caught-between accidents

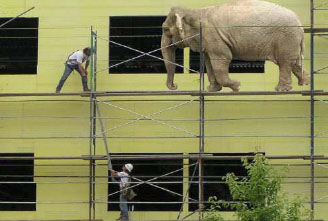

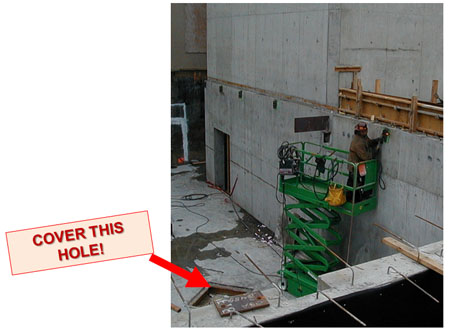

What’s wrong here?

WHAT YOU NEED TO KNOW AND DO TO LAST IN THIS PROFESSION

- Proper use of scaffolds and ladders

- Safety around moving vehicles and equipment

- Preventing falls

- Avoiding what can hit you

What’s wrong here?

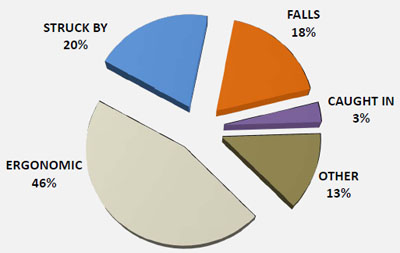

CEMENT MASONS REPORTED INJURY RATES 2006-2008

Source: Washington State Department of Labor and Industries

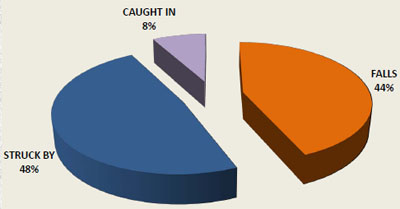

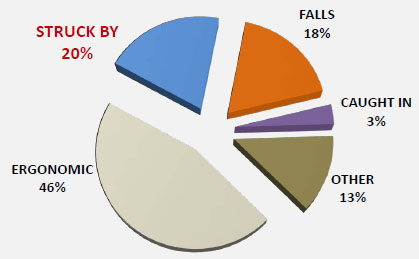

CEMENT MASONS FALL, STRUCK BY, CAUGHT IN INJURIES 2006-2008

Source: Washington State Department of Labor and Industries

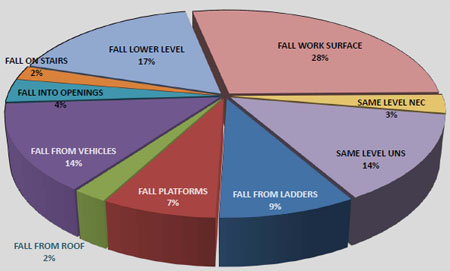

CEMENT MASON FALLS 2006-2008

Source: Washington State Department of Labor and Industries

FALLS

Falls are a major source of Cement Mason injuries, but they are preventable!

FALLS FROM PLATFORMS

RULES FOR SCAFFOLDS AND LIFTS

- CHECK THE GROUND CONDITION

- Too firm or too soft?

- Frozen? It might thaw and begin to sink.

- Is the base of the scaffold or lift level?

- Is it supported on proper adjustable stands?

- If it is a rolling scaffold, are the castor locks in good working order and locked when not being moved?

RULES FOR SCAFFOLDING

- Scaffolding must be able to support at least four times its intended load

- Anyone working in the vicinity of the scaffolding or on the scaffolding must wear a hard hat

- Anyone constructing or operating scaffolding must be certified

- Scaffolding platforms must be kept as clear as possible

- Do not use scaffolding in bad weather conditions like high winds, snow or icy conditions

RULES FOR SCAFFOLDING and LIFTS

- Never remain on the scaffold when it is being moved

- Must be checked daily

- If moving, secure all tools and materials

Use a hoist to haul tools, equipment or any loads up to and down from the scaffold.

Keep both hands free for you

What’s wrong here?

RULES FOR SCAFFOLDING

- Safe access to the scaffolding must be provided -- avoid the need to climb over cross bracing.

What’s wrong here?

MINIMUM Safe Distances from High Voltage Sources & Power Lines

| Power line voltage phase to phase (kV) | Minimum safe clearance (feet) |

| 50 or below | 10 |

| Above 50 to 200 | 15 |

| Above 200 to 350 | 20 |

| Above 350 to 500 | 25 |

| Above 500 to 750 | 35 |

| Above 750 to 1,000 | 45 |

RULES FOR POWER LINES: NOT JUST FOR SCAFFOLDS

REVIEW: SCAFFOLD RULES

- DO NOT use damaged or distorted parts on any scaffold.

- DO NOT allow anyone to be on scaffolds when they are feeling weak, sick, or dizzy.

- DO NOT work from any part of the scaffold other than the platform.

- DO NOT alter the scaffold or any of its parts.

- DO NOT move a scaffold horizontally while workers are on it, unless it is a mobile scaffold and the proper procedures are followed.

- DO NOT allow employees to work on scaffolds covered with snow, ice, or other slippery materials.

- DO NOT erect, use, alter, or move scaffolds within 10 feet of overhead power lines.

- DO NOT use shore or lean-to scaffolds.

- DO NOT swing loads near or onto scaffolds unless properly controlled by a tag line(s) -- and the load does not exceed the scaffold’s capacity.

- DO NOT work on scaffolds in bad weather or high winds unless you determine that doing so is safe.

- DO NOT use ladders, boxes, barrels, or other makeshift contraptions to gain additional height on your work platform.

- DO NOT let unused or scrap material accumulate on the platforms.

- DO NOT put more weight (including you) on a scaffold than it is designed to hold.

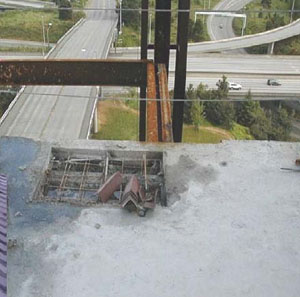

FALLS FROM LIFTS AND PLATFORMS

Scissors Lift Topples

FALLS FROM PLATFORMS

FALLS FROM LIFTS AND PLATFORMS

What prevents the lift wheel from falling into the hole?

FALLS TO WORK SURFACE

Caused by slipping, tripping or falling while walking or working:

- On unstable, loose or uneven, or oily surfaces

- In slippery, wet , or muddy conditions

- By tripping over obstacles, objects, materials or scrap

What’s wrong here? Name the obstacles.

KNOW WHERE YOU ARE AT ALL TIMES

- Know your surroundings when walking

- Be aware of tools and materials in walking/working areas, especially pneumatic or electric tools with hoses and cords

FALLS FROM LADDERS

- Keep manufactured and job-made ladders in good condition

- Inspect ladders before each use. Look for broken rungs or other defects. Destroy or repair defective ladders.

- Place ladders at the proper angle (1 foot out from the base for every 4 feet of vertical rise)

- Secure ladders near the top and/or at the bottom to prevent them from slipping

What’s wrong here? Is this safe?

Building it on site? Make it safe!

- Extend ladders at least 3 feet above the landing to provide a handhold and for balance when getting on and off the ladder from other surfaces

Use a hoist to move materials and equipment. KEEP BOTH HANDS FREE FOR YOU

- Use ladders only for what they were made –DO NOT USE as a platform, runway, or as scaffold planks.

- Always face the ladder and maintain 3 points of contact when climbing a ladder

- Do not set up a ladder near passageways or high traffic areas where it could be knocked over.

Does your ladder placement mean a fall PAST other safeguards?

FALLS SAME LEVEL

- Wear the proper foot gear.

- Walk slowly and never run on slick ground.

- Test potentially slick areas by tapping your foot on them.

- Keep walkways clear of water, ice, oil and slippery materials.

- Watch for tripping hazards.

- Always be sure that you can see over your load.

- Keep your eyes on where you are going.

- Avoid tripping hazards

- Any change in elevation is a major source of tripping.

- Even a change of ¼ -½ “ can cause a trip.

- Curbs, cracks, single steps are all hazards.

- When these helpful hints don't work, and you know you are going to slip, try to reduce your potential injury when falling by:

- Roll with the fall.

- Relax as much as possible when you begin to fall.

- Toss the load you are carrying. Protect yourself instead of the objects being carried.

- Prevent or mark jutting material that may not be seen when walking quickly or with vision obscured (carrying materials or tools)

FALLS AGAINST OBJECTS

What’s missing here?

- USE REBAR CAPS AND GUARDS

MAYBE JUST ONE WILL DO?

What are the hazards in this picture? Are they corrected?

THOSE MUDDY BOOTS COULD NEVER SLIP, RIGHT?

What is missing here?

FALLS TO LOWER LEVEL

Floor and Wall Openings

- Install guardrails around openings in floors and across openings in walls when the fall distance is 6 feet or more

- Make sure top rails can withstand a 200-lb load

- Construct guardrails with a top rail approximately 42” high and with a mid-rail about half that high (21”)

- Cover all floor openings larger than 2” x 2”with material that can safely support at least twice the anticipated working load

- Secure and mark the cover

- There is no excuse for not covering and securing and marking every floor and roof opening, regardless of size

- It’s actually better to build a guard rail around the opening so that it can be seen

HOW MUCH PROTECTION DOES CAUTION TAPE PROVIDE?

HOW MUCH PROTECTION IS THIS BARRIER PROVIDING?

FALLS FROM VEHICLES

- Step -don't jump -from vehicles or equipment

- Do not board or depart any vehicle or equipment that is moving

- Watch where you park!

FALLS FROM STAIRS

- Do not store materials on stairways

- Keep hazardous projections (such as materials, protruding nails, large splinters, etc.) off stairs, treads or handrails

- Correct slippery conditions on stairways before they are used

- Keep all cords, hoses and welding leads off the stair treads and risers

- Keep stairs clear of debris

Could you see this hazard?

PREVENT TRIPPING

How many ways to trip can you see?

PREVENT TRIPPING

WHAT COULD YOU DO? OR DO BETTER?

- Keep tools and supplies out of traffic areas

- Provide enough light for workers to see and to prevent accidents

TESTIMONIALS BY PEOPLE WHO HAVE HAD TO LEAVE THE PROFESSION DUE TO SERIOUS INJURY FROM FALLS

Kuhlman Corp

CEMENT MASONS STRUCK BY INJURY RATES 2006-2008

Source: Washington State Department of Labor and Industries

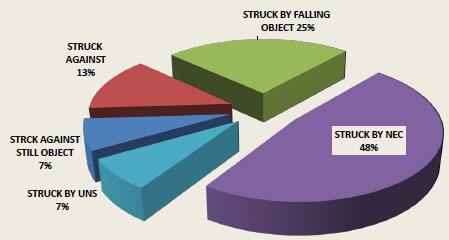

CEMENT MASONS STRUCK BY AND AGAINST INJURIES 2006-2008

Source: Washington State Department of Labor and Industries

STRUCK BY/AGAINST

Struck by/against:

- impact of a part of the body against something or

- hit by a moving or flying objects

- or by noise (noise impacts the ear drum)

When a worker is

- hit by work tools,

- by construction materials,

- by a vehicle, by equipment such as a backhoe bucket,

- by flying debris,

- by earth during a trench collapse, or

- by any other object

- When helping someone to hitch equipment or an implement to a truck or tractor, stand to the side. That way, the driver can see you. Also, you won’t be between the truck and the equipment.

- Never work under a vehicle or equipment that is supported only by a jack or stand. The jack or stand could tip, and the raised equipment then will be dropped on the person under it.

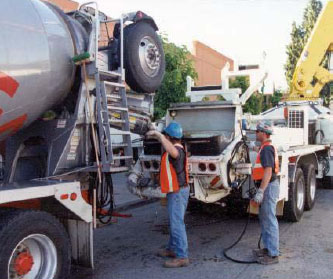

Who has potential for being struck on this site? Struck by what?

Concrete can “burp back” from the hopper

Stay back from the hopper of the concrete pump.

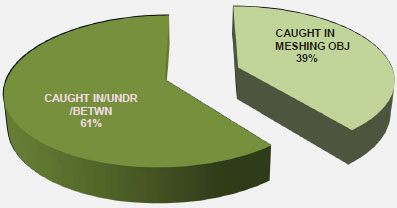

CEMENT MASONS CAUGHT IN INJURIES 2006-2008

Source: Washington State Department of Labor and Industries

CAUGHT IN & CAUGHT BETWEEN

CAUGHT IN/UNDER/BETWEEN - a part of the body is squeezed, pinched or crushed in machinery or materials

Reasons Caught-In and Caught-Between Accidents Happen

- Working on moving equipment

- Working under mental or physical stress

- Using unsafe equipment

- Lack of training or instructions

- Inadequate guarding on machines

- Incorrect hitching practices

- Distraction

CAUGHT BETWEEN

- Never assume that the driver of a vehicle or equipment operator SEES YOU.

- Vehicle and equipment operators must always look in the direction of travel.

- Always install safety locks or other safeguards before getting under or between two objects that have the potential of trapping you.

- While unloading or working on equipment, the wheels of equipment need to be pinned to hold them stationary.

- This procedure is called chocking. Position chocks to prevent vehicles from inadvertently moving in any direction.

Pixxzle/ iStockPhoto

CAUGHT IN/BETWEEN

- Safeguard against contact with moving machine parts.

- Shut off power, perform lockout/tagout, and release any remaining energy before unjamming, servicing, lubricating, or adjusting machinery.

- Replace guards after servicing and before resuming use of equipment.

Avoid wearing jewelry and tattered or loose clothing around machinery, and wear hair short or tucked inside clothing

- Avoid stepping or reaching across running equipment or machinery.

TESTIMONIALS BY PEOPLE WHO HAVE HAD TO LEAVE THE PROFESSION DUE TO SERIOUS INJURY FROM BEING STRUCK BY OR CAUGHT IN

Hoover Dam