Summary Statement

A discussion of electrocution including statistics, types of hazards, case studies and methods to avoid electrocutions.

Electrocution remains a major cause of deaths in construction. Part of the reason is that at home and on the job we take electricity for granted. This can lead to familiarity and a false sense of security. Relying on the benefits of electricity, we may forget its hazards.

Historically, electrocution accounts for about 20% of all fatalities in construction. Unfortunately, last year was no exception. Four of the twenty construction deaths in 1999 were electrocutions. All of the fatalities resulted from overhead contact with powerlines -- a boom truck in one case, ladders in the other three.

Overhead Contact

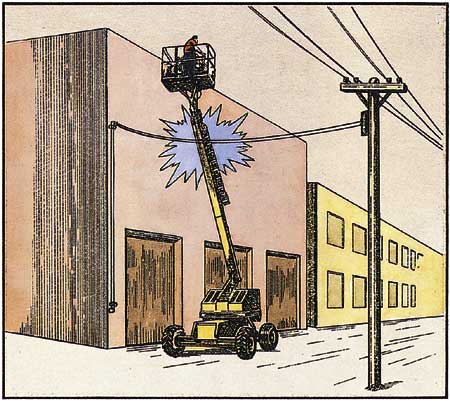

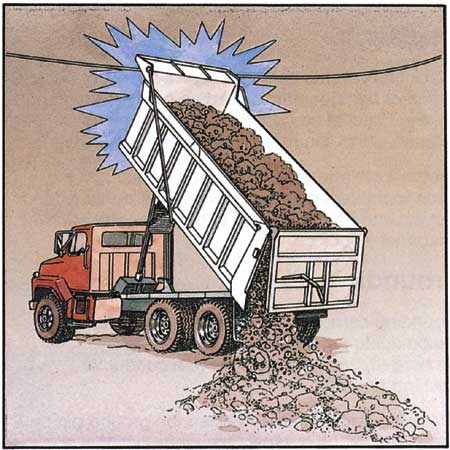

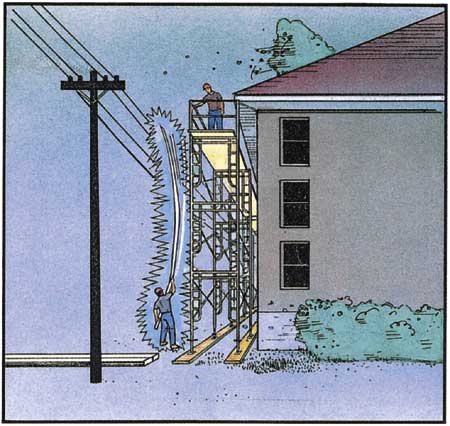

Some people think that only cranes are involved in overhead contacts. But backhoes, dump trucks, and low-tech equipment like ladders and rolling scaffolds have also been involved. Nor does it take high-tension lines to kill construction people. Too many fatalities involve residential service.

SAFEGUARDS

- Locate and identify

all overhead powerlines. Determine voltage before construction begins.

- Have lines moved,

insulated, or de-energized. In urban areas, insulating or "rubberizing"

powerlines is often most practical. Contact the local utility.

- Use a signaler

whenever a backhoe, crane, or similar device is closer than one boom

length to a live powerline of 750 volts or more.

- The signaler must

warn the operator when any part of the machine or its load approaches

the minimum distances allowed in the construction regulation.

Voltage ratingMinimum distance750 -150,000 volts3 meters151,000 - 250,0004.5 metersOver 250,000 volts6 meters

- Never use aluminum or metal-reinforced ladders near overhead lines or live electrical equipment or wiring. Even contact with a wooden ladder can be fatal under damp or wet conditions.

- Never store material or equipment under overhead powerlines if current is more than 750 volts and cranes or similar lifting devices will be involved.

- Where material or equipment must be stored under powerlines, hang warning flags so that personnel will not use hoisting and lifting equipment.

- Remember that overhead lines can be struck not only by booms and ladders but also by long pieces of material being lifted by hand, such as pipe and siding.

- Beware of wind swaying powerlines into contact with equipment, hoist lines, or loads. And beware of wind blowing hoist lines or loads into contact with powerlines.

In the event of contact between equipment and overhead powerlines:

Stay on equipment. Don't touch equipment and ground at the same time. In fact, touching anything in contact with the ground can be fatal.

Keep others away. Warn everyone not to touch the equipment or its load. That means buckets, outriggers, load lines, and any other part of the machine. Beware of time-delayed relays. Even after line damage trips breakers, relays may still try to restore power. They may reset automatically two or three times.

Break contact. If possible, break contact by moving the equipment clear of the wires. This may not be feasible where contact has welded conductors to equipment, hoist line, or load.

Call local utility. Get someone to call the local electrical utility for help. Stay on the equipment until the utility shuts down the line and confirms that power is off. Report every incident of powerline contact so that the utility can check for damage that could cause the line to fall later.

| Jump clear. If an emergency such as fire forces you to leave the equipment, jump clear. If part of your body contacts the ground while another part touches the machine, current will travel through you. In cases of high-voltage contact, jump clear and shuffle away in small steps. With voltage differential across the ground, one foot may be in a higher voltage area than the other. The difference could kill you. |  |

Case Histories

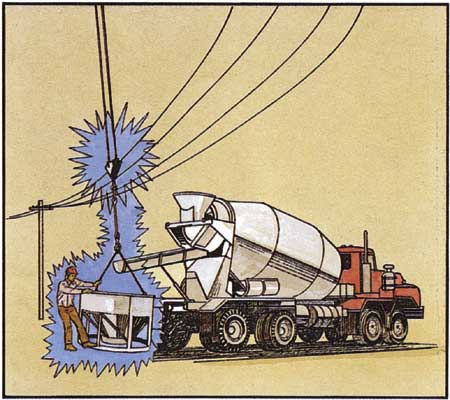

A tower crane was

lowering a concrete bucket to be filled by a truck. The wind blew the

hoist line and bucket into overhead powerlines. A worker trying to pull

the bucket back was electrocuted.

|

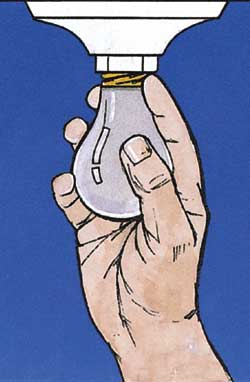

A worker was changing the bulb in a light fixture that had been incorrectly wired (polarity was reversed). He inadvertently touched the metal base of the bulb while it was in contact with the socket. He received a severe shock and later died in hospital |

|

Polarity

When installing switches, receptacles, fixtures, and other equipment, be sure to respect the color code in wiring. As always, only an electrician or person with equivalent qualifications should install electrical equipment. Otherwise polarity may be reversed with dangerous results. Switches may remain energized when turned off, for instance, and GFCIs may not work properly. |

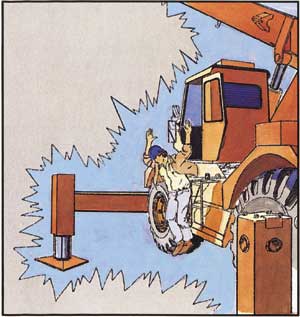

Underground Contact

Construction personnel have been electrocuted by contacting buried powerlines. One incident involved using an auger attachment on a Bobcat to drill holes for fence posts. The auger struck a live underground line, electrocuting a worker who was standing on the ground and touching the machine. The operator remained in the cab and was not injured.

SAFEGUARDS

- Before construction begins, ask the local electrical utility to locate and mark all buried services.

- Indicate underground lines on all plans and drawings. Post warning signs along their route.

- Ensure that warning signs remain in place during construction.

Grounding

Grounding is an essential concept in electrical safety. It can be intentional and work for you, or accidental and work against you. Grounding is a connection between an electrical circuit and the earth or some conducting body that serves as earth. The point is: you don't want that "body" to be yours.

Grounding carries current from faulty wiring, tools, or equipment to a point where it can be safely discharged, usually to earth or a conductor touching earth. Grounded tools and equipment help to prevent you from becoming the means of channeling electricity back to earth.

SAFEGUARDS

- Don't cut off

or bend back the ground pin on a three-prong plug. Don't use a two-prong

cheater or adapter. Don't replace three-wire cord with two-wire cord

on tools and equipment. These practices are dangerous and, in most jurisdictions,

illegal.

- Check extension

cords and outlets for grounding with a circuit-tester before using.

- Ensure that all

electric hand tools are grounded or double-insulated. Double-insulated

tools are made of non-conducting plastic. External metal parts are insulated

from internal electrified parts. Make sure that casings are not cracked,

broken, or otherwise defective.

- Don't hold onto

a water pipe or other grounded conductor when using an electric tool.

The tool or cord could be defective and you might be electrocuted.

- Use ground fault circuit interrupters (GFCIs) on all electric tools. Ontario law requires GFCIs with tools used outdoors and in damp locations. GFCIs detect any current leaking to ground and shut off power before injury or damage can occur.

Case Histories

|

A worker was painting a building from a boom-type powered elevating work platform. He backed up without checking how close he was to a powerline. The machine touched the line. Trying to escape from the bucket he climbed onto the roof and was electrocuted |

| A driver raised the box on his dump truck to spread gravel under a powerline. When the box contacted the line, he got out of the cab to see what had happened. His foot touched the ground while his hand was still holding the door. He was electrocuted instantly |  |

|

Two aluminum siding installers were lifting trim for the exterior of a house. Although aware of nearby powerlines, they failed to allow for the length or bulkiness of their material. A piece of trim shifted as it was lifted, struck a line, and one worker was electrocuted |

|

Ontario Construction -- Electrocutions in 1999

|

Electric Shock

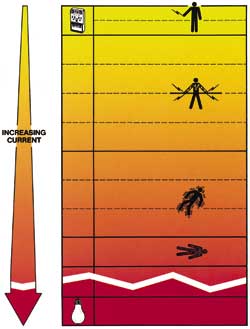

The effect of electric shock on the human body is determined by three

main factors:

- how much current is flowing through the body (measured in amperes and determined by voltage and resistance)

- the path of current through the body

- how long the body is in the circuit.

|

Mild Shock Trip setting for ground fault circuit interrupter Muscle Contractions Victim cannot let go Severe Shock Breathing difficult - possible respiratory arrest Heart Stops pumping Increasing probability of death

|

Effects can range from a tingle to cardiac arrest. There is no exact way to predict the injury from any given amperage. The table below shows generally how degree of injury relates to current passing through a body for a few seconds.

This is the third in a series of articles dealing with the major causes of construction fatalities. Falls were covered in Volume 10, Number 3 (Autumn 1999) and traffic in Volume 10, Number 4 (Winter 1999/2000).