Summary Statement

A training booklet for high school students about silica exposures and lung damage, focusing on 10 sandblasters who had silicosis.

2002

| This training booklet for high school students provides clear information about silica exposures and how to prevent resulting lung damage, while focusing on 10 sandblasters at one company in Texas, who had silicosis in 1988-89. One of the workers , age 34, died. (Silica is found in quartz and other rock. Other construction trades at risk of silica exposures include bricklayer/mason, cement/concrete, drywall, and laborer.) The booklet explains the use of engineering controls, work practices (such as wet methods to reduce dust), respirators, air monitoring. One section mentions a case in 1936, known as the Hawk's Nest incident, when more than 1,000 workers tunneling through a mountain in West Virginia are believed to have died from silicosis on the job. Contains a glossary. |

This document

is in the public domain and may be freely copied or reprinted.

DISCLAIMER

Mention of any company

or product does not constitute endorsement by NIOSH.

ORDERING INFORMATION

To receive documents

or other information about occupational safety and health topics, contact

the National Institute for Occupational Safety and Health (NIOSH) at

NIOSH - Publications Dissemination 4676 Columbia Parkway Cincinnati,

OH 45226-1998

Telephone: 1-800-35-NIOSH (1-800-356-4674)

Fax: 513-533-8573

E-mail: pubstaft@cdc.gov

or visit the NIOSH Web site at www.cdc.gov/niosh

DHHS (NIOSH) Publication Number 2002-105

June 2002

NIOSH Case Study in Occupational Epidemiology

GOAL - To learn about epidemiology by studying an occupational

hazard, a disease associated with the hazard, and the methods for preventing

the disease. Epidemiology is the study of why and how a disease occurs

and spreads in populations. The purpose of epidemiology is to prevent

and control disease by identifying its causes and the methods for control.

Occupational epidemiology is the study of disease or injury related

to work activities and the worksite.

Congress passed the Occupational Safety and Health Act in 1970 to assure

every working man and woman in the United States a safe and healthful

workplace. Although we have made progress since that time, serious problems

still occur and result in illness, injury, disability, and death. Preventing

these tragedies requires the cooperation and effort of everyone concerned.

More than 2 million U.S. workers are potentially exposed to dusts containing

crystalline silica. Prolonged inhalation of silica-containing dusts

puts these workers at risk for the disease silicosis-a nodular fibrosis

of the lungs that causes shortness of breath. More than 100,000 U.S.

workers are in high-risk occupations such as sandblasting. Most sandblasters

work in construction and shipbuilding. Workers may be ex- posed to crystalline

silica in many other industries, including surface and underground mining,

pottery, drywall hanging, glassmaking, foundry work, quarry work, work

with sandblast- ing materials, agriculture, and automotive repair.

After completing this case study, the student should be able to do the

following:

- Use occupational health and epidemiologic approaches to solve real-life problems

- Understand how public health and occupational health professionals work together to solve occupational health problems

- Recognize that silicosis (even in only one worker) is a serious occupational disease requiring that the work- place be checked for dangerous conditions and that other workers be checked for silica-related disease

- Assess hazards that place workers at risk for silicosis

- Describe methods

for preventing silicosis

Abrasive blasting - Aprocess for cleaning metal and other surfaces using material in a high-pressure stream. The material is blasted against a surface to remove paint or contaminants. If sil- ica sand is used as the material, this process is called sandblasting.

Accelerated silicosis - A silicosis that develops 5 to 10 years after exposure to high concentrations of crystalline silica.

Acute silicosis - A silicosis with symptoms that can develop a few weeks to 5 years after exposure to very high concentrations of crystalline silica. The term "acute" usually refers to a short but severe illness. In acute silicosis, the time between exposure and severe illness is shorter than in accelerated or chronic silicosis.

Air monitoring - The use of specialized equipment to measure types of pollutants and their concentrations in the atmosphere.

Automation - The replacement of human or animal labor by machines. One example is the use of robots or remote-controlled equipment for lifting and transporting materials.

Biopsy - The removal and examination of tissue, cells, or fluids from a living body for diagnosis of disease.

Chronic silicosis - A silicosis that develops after 10 or more years of exposure to low concentrations of crystalline silica.

Crystalline silica - The crystalline form of silica; a mineral made of silicon and oxygen (SiO2) that is naturally abundant in the earth's crust. In its crystalline form (primarily as quartz, tridymite, or cristobalite), silica may be harmful if inhaled.

Cyanosis - A bluish or purplish discoloration due to inadequate oxygen concentration in the blood. This discoloration is most often seen in the skin, but it occurs in other body systems.

Engineering controls - Methods of controlling worker exposures to hazardous agents by adjusting the source or reducing the amount released in the workplace. Examples include a change in process, substitution of less harmful job activities or materials, isolation, and ventilation. Engineering controls are the preferred method for targeting worksite hazards.

Epidemiology - The study of why and how a disease occurs and spreads in populations.

Fibrosis - Scarring of the lungs due to breathing harmful dusts or chemicals such as crystalline silica. As the disease develops, the lungs begin to stiffen and become less flexible, making breathing more difficult.

Fit testing - A procedure for checking to see that a respirator fits properly and does not allow pollutants to be inhaled.

Industrial hygiene - The applied science of recognizing, evaluating, and controlling factors in the workplace that may cause illness or injury for workers.

Local exhaust ventilation - An air movement system for capturing pollutants in the air directly where they are produced and carrying them away before they can spread throughout the work area.

Material safety data sheet (MSDS) - A written summary of important safety and health information about a chemical or substance. Manufacturers must supply the MSDS for each hazardous agent purchased. Employers must make the MSDS available to employees for each hazardous agent used.

Mine Safety and Health Administration (MSHA) - AFederal agency within the U.S. Department of Labor. MSHA develops and enforces regulations for workplace safety and health in the mining industry.

National Institute for Occupational Safety and Health (NIOSH) - A Federal occupational safety and health research agency within the Centers for Disease Control and Prevention, U.S. Department of Health and Human Services. NIOSH also communicates safety and health information to workers, employers, and government agencies such as the Occupational Safety and Health Administration (OSHA).

Occupational Safety and Health Administration (OSHA) - A Federal agency within the U.S. Department of Labor. OSHA develops and enforces regulations for workplace safety and health.

Outbreak - A sudden increase in the number of new cases of a disease in a geographic area.

Particulate - A particle or small object made of a solid or liquid material.

Pneumonia - A lung disease caused by infection or irritants and characterized by inflammation.

Pneumoconiosis - A lung disease caused by inhaling hazardous dusts.

Protective clothing - Any clothing designed or intended to be worn as protection from exposures to harmful agents such as chemicals.

Pulmonary edema - An abnormal accumulation of fluid in the lungs.

Respirable particles - Airborne particles within a size range that allows them to be inhaled and to penetrate deeply into the lungs.

Respirator - A device worn over the mouth and nose or entire head to protect the user from inhaling harmful agents.

Respiratory protection program - A plan established by an employer to protect workers from inhaling harmful agents in the workplace. The elements of a respiratory protection program are described under Question 6 in the text.

Sandblasting - A process for cleaning metal and other surfaces using sand in a high-pressure air stream. The sand is blasted against a surface to remove paint or contaminants. This process is also called abrasive blasting.

Silica sand - The fine particles from ground rock containing a high content of crystalline silica.

Silicosis - A nodular fibrosis of the lungs and shortness of breath caused by prolonged inhalation of silica-containing dusts.

Silicotic nodule - Amass of tissue that is a reaction of the body to crystalline silica particles.

Source controls - Any engineering change made to eliminate or reduce exposures at the point where the hazard is generated (for example, enclosing equipment, putting up a barrier to the equipment, and using wet methods, dust collection systems, and substitution).

Substitution - The removal of a harmful agent from a process and its replacement with an agent that is less harmful to health.

Supplied-air respirator - A protective device that delivers fresh (uncontaminated) air to the user through a supply hose connected to the facemask or enclosure.

Wet methods - The use of water or another suitable liquid with industrial processes (cutting, sanding, grinding) to reduce dust concentrations in the air.

Work practices - The procedures followed by employers and workers to control hazards in the workplace (for example, use of wet methods to control dust).

PART I. CASE STUDY

Question 1. How did epidemiologists find out what caused a silicosis outbreak in Texas?

In November 1988, a doctor in Texas reported three cases of silicosis to his local health department. These workers went to the doctor because they were becoming very short of breath. All three men worked at a facility where they sandblasted oil-field drilling pipes. One of the workers (aged 34) died of acute silicosis. The doctor reported the cases to the health department because silicosis is a very serious occupational disease. The doctor knew that the facility where these people worked might be hazardous. The doctor wanted the facility to be checked by the local health department to protect other people from developing silicosis. Recognition of silicosis usually signals a serious problem in the workplace.

The county health department and the Texas Department of Health contacted other local doctors and identified seven more workers who had suffered from silicosis since 1985. Thus the health departments identified a total of 10 workers who had been diagnosed with silicosis. Epidemiologists from the Texas Department of Health conducted an investigation of the workers with silicosis. The investigators reviewed personal and occupational histories from each worker who had been diagnosed with silicosis. They reviewed lung biopsy reports and inspected the facility for hazardous agents. The workers' chest X-rays were examined for lung diseases.

Each of the 10 workers had been exposed to crystalline silica at the workplace. Their chest X-rays were all abnormal and showed pneumoconiosis. Nine of the workers had abnormal lung biopsy reports of silicotic nodules or acute silicosis. The workers' ages ranged from 24 to 50 at the time of diagnosis. Seven workers were under age 30.

All 10 workers had used sandblasting machines for periods of 18 months to 8 years (the average was 4.5 years). Nine workers reported no silica exposure before working at the current site. The other worker had sandblasted oil-field drilling equipment for 3 years before working at the current site for 5 years. The epidemiologists from the Texas Department of Health consulted with occupational safety and health experts (called industrial hygienists) to learn more about the industrial processes that could have caused silicosis at this facility.

The sandblasting process at the facility used a blasting rod with a sandblasting agent containing 20.5% crystalline silica sand. The rod, which was connected to a high-pressure air supply hose, was held by the worker and directed through the drilling pipe. The abrasive silica sand from the rod was air-blasted against the inner walls of the pipe. This process removed contaminants to create a cleaner, smoother interior surface for application of a protective plastic coating. Although the sandblasting operation was enclosed by blasting cabinets connected to exhaust systems, the cabinets were in poor condition and permitted clouds of dust to be released throughout the work area. Workers stood inside booths intended to protect them from inhaling crystalline silica. However, the booths actually increased the workers' inhalation of crystalline silica by drawing their air from surrounding areas with high silica contamination. Workers then shoveled the used sandblasting mixture into the machinery for reuse.

In March 1989, air samples collected in the workers' breathing zones showed high concentrations of crystalline silica in the sandblasting area.

PART II. UNDERSTANDING SILICOSIS

Question 2. What is silica and what are the possible dangers of working with silica?

Silica may be of several distinct types. For example, quartz is a crystalline form of silica and is the most common mineral in the earth's crust. When rock containing quartz is chipped, hammered, drilled, crushed, loaded, hauled, or dumped, small particles of silica are released into the air and can be inhaled by workers.

Silica sand containing quartz is used in sandblasting equipment to clean surfaces. The outsides of buildings and bridges and the insides of storage tanks and pipes are some of the surfaces that are cleaned by sandblasting.

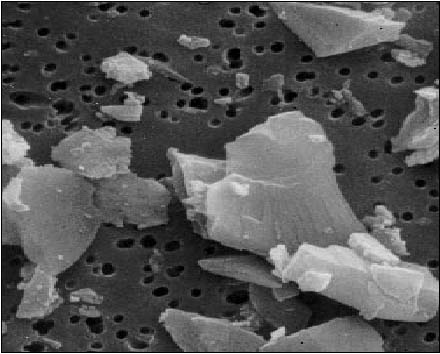

The silica sand used in sandblasting breaks into fine particles that stay in the air (Figure 1). If these particles are small enough to be inhaled deeply into the lungs, they are known as respirable crystalline silica. Inhaling these fine silica particles causes more lung damage than inhaling larger particles. This process causes rapid and severe forms of silicosis in sandblasters.

Figure 1. Detailed microscopic view of silica particles on a filter. (Scanning electron micrograph by William Jones, Ph.D.)

When workers inhale crystalline silica, the lung develops scar tissue around the silica particles. This process results in a lung disease known as silicosis. As more lung tissue is damaged by silica dust, breathing becomes more difficult, chest pain occurs, and death may result. Silicosis patients suffer shortness of breath, fever, and cyanosis. Some patients are diagnosed incorrectly as having pulmonary edema, pneumonia, or other lung diseases.

The three types of silicosis are as follows:

- Chronic silicosis, which occurs after 10 or more years of exposure to low concentrations of crystalline silica.

- Accelerated silicosis, which occurs 5 to 10 years after exposure to high concentrations of crystalline silica.

- Acute silicosis, which occurs a few weeks to 5 years after exposure to very high concentrations of crystalline silica.

|

Hawk's

Nest Incident

Descriptions of chronic silicosis have been available since the late 1800s. But acute silicosis first received widespread public attention in 1936, when Congress investigated reports of 1,500 cases of workers with acute silicosis near the town of Gauley Bridge, West Virginia. The incident has been called "America.s worst industrial disaster." The workers were hired to tunnel through a mountain with a very high concentration of silica. As a result, the workers were exposed to high concentrations of silica dust in the air while they were working. More than 1,000 of these workers are believed to have died from acute silicosis caused by their silica exposure on this project. Almost no precautions were taken against inhalation of silica. These events are described in the book The Hawk's Nest Incident: America's Worst Industrial Disaster, by Martin Cherniak. |

Question 4. How many workers are exposed to dusts containing crystalline silica?

More than 2 million U.S. workers are potentially exposed to dusts containing crystalline silica. More than 100,000 of them are in high-risk occupations, including sandblasting. Most sandblasters work in construction and shipbuilding. Workers may be exposed to crystalline silica in many other industries, including surface and underground mining, pottery, drywall hanging, glassmaking, foundry work, quarry work, work with sandblasting materials, agriculture, and au- tomotive repair.

PART III. PREVENTION OF SILICOSIS

Question 5. What fields of occupational health protect workers from occupational hazards?

Industrial hygiene is the science of recognizing, evaluating, and controlling hazards in the workplace and environment. Industrial hygiene practices protect workers from hazards. Other professionals important for protecting workers' health include occupational health physicians and nurses as well as engineers.

Question 6. What practices are used to protect workers from silicosis?

Industrial hygiene practices are used to protect workers from silicosis and other workplace hazards. These practices include the use of substitution, engineering controls, work practices, respiratory protection, and air monitoring. Employers are responsible for implementing these practices when they are needed to provide safe and healthful workplaces.

Substitution

|

|

NIOSH has studied several abrasive agents that might be used as substitutes for silica sand during sandblasting. Some of the abrasives studied are steel grit, specular hematite, nickel slag, copper slag, crushed glass, garnet, staurolite, olivine, and coal slag. Most of these abrasives work as well as silica sand and cost about the same or even less. However, the use of a substitute may have other adverse effects. Regardless of the type of abrasive, NIOSH recommends the use of engineering controls, work practices, respiratory protection, and air monitoring (all described below) to reduce hazards to workers during sand- blasting. Figure 2 illustrates good work practices and the proper use of personal protective equipment for abrasive blasting.

Engineering Controls

Engineering controls are hazard controls designed into equipment and workplaces. Examples of engineering controls are

- automated equipment operated from an enclosed booth,

- enclosed blast-cleaning machines and cabinets,

- tools with dust collection systems, and

- local exhaust ventilation.

Figure 2. Sandblaster using proper respiratory protection inside a ventilated booth. Note that the worker is supplied with two separate air lines - one to supply fresh air for the worker to breathe and the other to supply air for sandblasting.

Engineering controls are sometimes called source controls when they are designed to eliminate or reduce exposures at the source.

Work Practices

Work practices are procedures followed by both employers and workers to control hazards in the workplace. Examples of work practices are

- wet drilling

or sawing of silica-containing materials,

- showering and

changing into clean clothing before leaving work, and

- avoiding smoking, eating, and drinking in dusty areas.

Respiratory protection prevents workers from inhaling pollutants. Appropriate respiratory protection equipment and programs should be provided whenever engineering controls and work practices cannot keep concentrations of airborne silica at or below safe limits.

Respirators - Workers can wear special protective equipment called respirators to protect them from inhaling respirable crystalline silica. Respirators are a good option as protective equipment, but they should be used only when controls (such as substitution, automation, enclosed systems, and local exhaust ventilation) cannot keep exposures at or below safe limits.

Workers who perform sandblasting must use the type of respirator recommended by NIOSH for their particular job. Regardless of the abrasive used, NIOSH recommends a respirator that provides a constant supply of clean air through a line that connects to a hood or helmet worn by the worker. The respirator air line must be separate from the line that supplies air for blasting. This device is known as a type CE abrasive-blasting respirator operated in the continuous-flow mode.

Respiratory Protection Program - To make sure that respirators are used properly, the employer must establish a comprehensive respiratory protection program as required in the OSHA respiratory protection standard of 1998 (see the NIOSH Guide to Industrial Respiratory Protection for guidance). The following are important elements of this standard:

- Periodic air

monitoring

- Regular training

of workers in respirator use

- Selection of

proper NIOSH-approved respirators

- A medical determination

of the worker's ability to perform the work while using a respirator

- Respirator fit

testing

- Maintenance, inspection, cleaning, and storage of respirators The respiratory protection program should be evaluated regularly by the employer.

Air-monitoring equipment measures air pollutants such as silica to assess worker exposure. Industrial hygienists and air-sampling technicians perform air monitoring. The samples from air monitoring are analyzed to identify concentrations and types of pollutants in the air. The results of air monitoring for crystalline silica are used to select and evaluate engineering controls and respiratory protection. These air monitoring results are also compared with exposure limits that are required or have been recommended on the basis of health studies of animals and humans. NIOSH, OSHA, and MSHA have exposure limits for respirable crystalline silica. For more information about these exposure limits, see Suggested Reading List and Other Useful Resources in Question 8.

Question 7. What else is done to detect and control silicosis in a workplace?

Medical exams should be offered to all workers who may be exposed to respirable particles of silica. Each exam includes a job history, a medical history, and a physical exam. The job history questionnaire asks about all the jobs the worker has had, all the materials worked with, and all protective equipment used. These exams should occur before job placement or entry into a trade. Workers should continue to have followup medical evaluations as well as careful monitoring of their work and exposures.

Question 8. What steps can employers take to prevent silicosis in workers who work with crystalline silica?

- Use abrasive

blasting materials that are less hazardous than those containing more

than 1% crystalline silica. Because substitute abrasives may also

have toxic effects, NIOSH recommends the use of engineering controls,

work practices, and respiratory protection for all abrasive blasting,

regardless of the type of abrasive used.

- Recognize situations

in which silica dust may be generated; plan to eliminate or control

dust at its source.

- Inform workers

about their exposures to crystalline silica dust, the possible health

effects of this dust, and the risk of silicosis.

- Establish effective

programs for monitoring the exposure of workers to crystalline silica

dust. Conduct air monitoring to measure worker exposure and check

that controls are working properly.

- Train workers

about safe work practices to reduce exposure to crystalline silica.

For example, workers should remove dust from equipment with a water

hose instead of compressed air. Use vacuums with high-efficiency particulate

air filters (HEPA filters). Use wet sweeping instead of dry sweeping.

- Post warning

signs to mark the boundaries of work areas that may be contaminated

with respirable crystalline silica.

- Provide workers

with material safety data sheets (MSDSs) for silica, masonry products,

alternative abrasives, and other hazardous materials to which they

may be exposed.

- Provide workers

with information about safe handling, labeling, and storage of toxic

materials.

- Write all signs,

labels, instructions, and other material for workers in easy-to-read

English and in any other languages needed for workers' understanding

of the material.

Provide engineering controls such as containment methods (enclosed blast-cleaning machines and cabinets). Provide equipment for wet drilling or wet sawing of silica-containing materials. Make sure workers use tools with dust collection systems. Use local exhaust ventilation to prevent release of dust into the air.

- Provide appropriate

respiratory protection for workers, including NIOSH-certified respirators

and a respiratory protection program to ensure proper use and maintenance

of respirators.

- Provide regular

medical exams for workers who may be exposed to respirable crystalline

silica.

- Provide either

disposable protective clothes or protective clothes that are laundered

at the workplace.

- Provide areas

for workers to shower and change into clean clothes before leaving

the worksite. This practice prevents contamination of other work areas,

cars, and homes.

- Report all cases of silicosis to state health departments and to OSHA (1-800-321-6742) or MSHA(1-800-746-1553).

- Use proper

respiratory protection when engineering controls cannot keep silica

exposures at or below safe limits.

- Remove dust

from equipment with a water hose instead of compressed air. Use vacuums

with HEPA filters. Use wet sweeping instead of dry sweeping.

- Change into

disposable protective clothes at the worksite.

- Shower and

change into clean clothes before leaving the worksite to prevent contamination

of other work areas, cars, and homes.

- Do not eat,

drink, use tobacco products, or apply cosmetics in dusty areas.

- Wash hands

and face before eating, drinking, or smoking outside dusty areas.

- Do not park cars where they can be contaminated with silica or other pollutants.

Question 10. What additional information is avail- able about preventing silicosis?

Additional information about preventing silicosis is available in the publications on the following Suggested Reading List and from the Other Useful Resources listed at the end of this document. Note that the NIOSH documents on this list are available at the Web site printed at the end of each reference. Single copies of NIOSH documents are also available free from NIOSH at

1-800-35-NIOSH (1-800-356-4674)

Fax: 513-533-8573

E-mail: pubstaft@cdc.gov

SUGGESTED READING

Cherniak M[1986]. The Hawk's Nest incident: America's worst industrial disaster. New Haven, CT: Yale University Press.

CPWR [1999]. Silica in sandblasting and rock drilling: hazard alert.Washington, DC:TheCentertoProtectWorkers' Rights.

DiNardi SR, ed. [1997]. The occupational environment-its evaluation and control. Fairfax, Virginia: American Industrial Hygiene Association.

NIOSH [1987]. NIOSH guide to industrial respiratory protection. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 87-116 (full text of document is available at http://www.cdc.gov/niosh/docs/87-116/).

NIOSH [1992]. NIOSH Alert: request for assistance in preventing silicosis and deaths from sandblasting. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 92-102 (full text of document is available at www.cdc.gov/niosh/92-102.html).

NIOSH [1996]. NIOSH Alert: request for assistance in preventing silicosis and deaths in construction workers. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 96-112 (full text of document is available at www.cdc.gov/niosh/consilic.html).

NIOSH [1997]. Construction workers: it's not just dust! Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 97-101 (full text of document is available at http://www.cdc.gov/niosh/docs/97-101/).

NIOSH [1997]. NIOSH pocket guide to chemical hazards. Cincinnati, OH: U.S. Department of Health and Human Services, Public Health Service, Centers for Disease Control and Prevention, National Institute for Occupational Safety and Health, DHHS (NIOSH) Publication No. 97-140 (full text of document is available at www.cdc.gov/niosh/npg/npg.html).

NSC [1996]. Fundamentals of industrial hygiene. 4th ed. Chicago, IL: National Safety Council.

Parkes WR [1994]. Occupational lung disorders. 3rd ed. Oxford, England: Butterworth-Heinemann, Ltd.

OTHER USEFUL RESOURCES

CPWR – Center for Construction Research and Training (CPWR)

Telephone:1-301-578-8500

Web site: www.cpwr.com

Mine Safety and Health Administration (MSHA)

Toll-free telephone: 1-800-746-1553

Other telephone: 1-703-235-1452

Web site: www.msha.gov

National Institute for Occupational Safety and Health (NIOSH)

Toll-free telephone: 1-800-35-NIOSH (1-800-356-4674)

Web site: www.cdc.gov/niosh

Occupational Safety and Health Administration (OSHA)

Toll-free telephone: 1-800-321-OSHA (1-800-321-6742)

Web site: www.osha.gov

ACKNOWLEDGMENTS

This module was prepared by NIOSH staff. The principal author was Bonita D. Malit, M.D., M.P.H. Thomas J. Lentz, Ph.D., assisted with the industrial hygiene sections. Gregory Loos, Ph.D., and Faye L. Rice also contributed to this module. Susan Feldmann and Anne C. Hamilton provided editorial review and Susan Kaelin provided design and layout of the document.