Summary Statement

All hooks on all FallTech Lanyards, Rebar Chain Assemblies, Harness/Lanyard Combos and Roofer’s Kits with manufacturing dates of 01/01/2012 through 01/25/2013 should be inspected immediately in accordance with this notice. FallTech has found defective “Snap Hook” and “Rebar Hook” products manufactured by YOKE Industrial Group. This inspection advisory is not a product recall. It is a step-by-step set process for checking fall protection products from FallTech to ensure they are not defective.

February 1, 2013

February 1, 2013

Product Inspection Advisory Notice – Immediate Action Required

Products Involved: FallTech Lanyards, Rebar Chain Assemblies , Harness/Lanyard Combos, and Roofer’s Kits

Manufacture Dates: 01/01/2012 through 01/25/2013

Serial Numbers: 0776186 through 1218826

Dear Valued Customer,

Please be advised that all hooks on all FallTech Lanyards, Rebar Chain Assemblies, Harness/Lanyard Combos and Roofer’s Kits with manufacturing dates of 01/01/2012 through 01/25/2013 should be inspected immediately in accordance with this notice.

During its regular raw material inspection, FallTech has found defective “Snap Hook” and “Rebar Hook” products manufactured by YOKE Industrial Group.

While FallTech has taken containment actions to prevent FallTech lanyards, rebar chain assemblies, Harness/Lanyard Combos and Roofer’s Kits produced using these defective hooks from reaching its customers, and no customer has alerted Falltech of this condition, there is still the possibility that a FallTech product with a defective hook(s) may be present in the field.

Please read this notice carefully. It will explain 1) how to determine if you have products that fall within the scope of this notice, 2) how to inspect products that are included in the notice and to determine whether they have a defective hook, 3) what to do if products have a defective hook, and 4) information on the root cause of the defect

PLEASE NOTE: This is an inspection advisory. This is a NOT a product recall. No product with a defective hook is known to have left the FallTech factory and no incidences of a product malfunction have been reported. If the defective condition exists, it can be found by following the inspection procedure described below.

1. IDENTIFYING PRODUCT THAT NEEDS TO BE INSPECTED

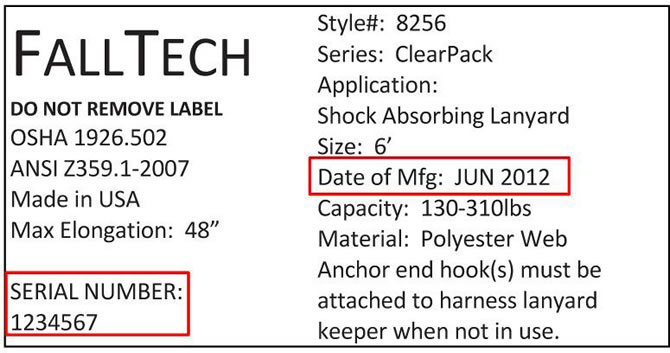

If you have purchased any FallTech Lanyard, Rebar Chain Assembly, Harness/Lanyard Combo, or Roofer’s Kit with a Date of Manufacture between 01/01/2012 and 1/25/2013 and a Serial Number marking between 0776186 and 1218826 it may have been manufactured using a YOKE Industrial Corp. hook product, and if so, will be subject to this inspection notice. To determine the Date of Manufacture and Serial Number of your FallTech product please review the product label (See Figure 1 below demonstrating typical Date of Manufacture and Serial Number labeling). To determine if the product’s hook was manufactured by YOKE Industrial Corp. please look for the large “Y” marking on the hook body (See Figure 2).

If your FallTech Lanyard, Rebar Chain Assembly, Harness/Lanyard Combo, or Roofer’s Kit meets the above criteria, please remove it from service immediately and quarantine the product from all other equipment in use or available for use, and proceed with the inspection procedure described in section 2 and 3 of this notice.

Figure 1: Example of typical Date of Manufacture and Serial Number Label.

Figure 2: Typical YOKE Industrial Corp. hook markings.

2. INSPECTION PROCEDURES – Please evaluate quarantined product according to the following procedure

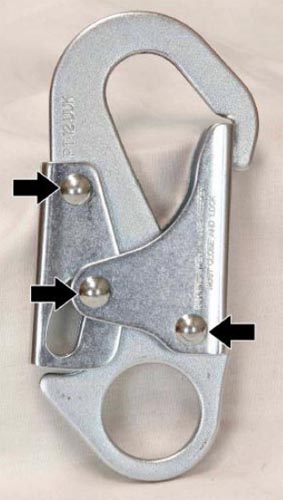

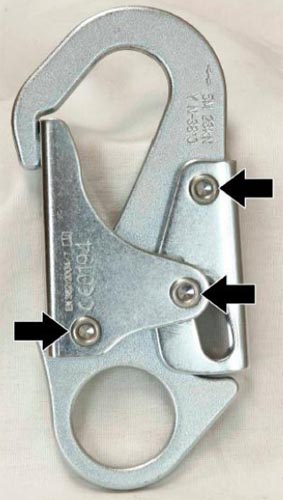

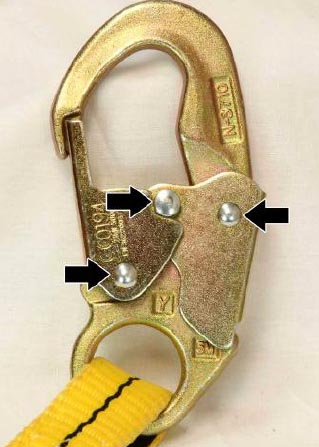

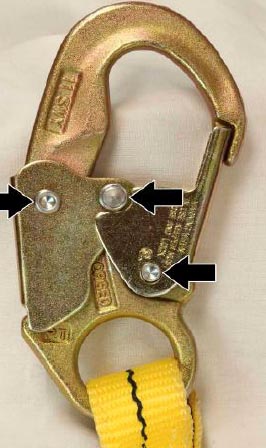

A. Locate on each product’s hook the fastening rivets used to assemble the hook (See Figures 3, 3A, 4, 4A). Note that the fastening rivet has two different end appearances when it is pressed onto the hook body, a rivet head (see Figure 3, 3A) and a pressed “tail” end (see Figure 4, 4A).

Figure 3: typical rivet head locations on stamped hook

Figure 4: typical pressed “tail” end rivet locations on stamped hook

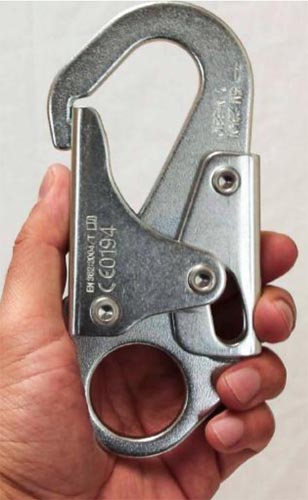

Figure 3A: typical rivet head locations on forged hook

Figure 4A: typical pressed “tail” end rivet locations on forged hook

B. Once the rivets have been located, hold the hook in your hand and view the hook from its side to determine which side has the “tail” end of the hooks rivets(see Figure 5).

Figure 5: Picture of hook with “tail” of rivets exposed

C. Turn hook to side (See Figure 6) and push firmly on the pressed “tail” end of the rivet with your thumb or finger and attempt to loosen or unseat the rivet from the hook body (See Figures 6A, 6B). If the defect explained in this notice is present, the rivet will move to allow full removal of an un-pressed rivet from the body of the hook by hand, without the use of any special tools (see Figure 7). DO NOT attempt to remove any pressed rivets, or use any tools or machinery that may cause damage to non-defective hooks.

Figure 6: Turn hook to side and push “Tail” end of rivets with thumb or finger

Figure 6A: Attempt with pressure to unseat rivet

Figure 6B: Use opposite hand to pull rivet free of hook

Figure 7: Fully removed rivet

D. If the hook demonstrates the defect shown in Figures 6, 6A, 6B and/or 7 follow the directions in Section 3 of this notice.

*If the rivets in your hook are properly pressed you will not be able to remove them and the hook is not defective

3. DISPOSITION of PRODUCTS THAT FAIL INSPECTION

If any FallTech Lanyard, Rebar Positioning Assembly, Harness/Lanyard Combo, or Roofer’s Kit fails to pass the inspection procedures described in Section 3 of this notice, please immediately remove the product from service and contact FallTech Customer Service at 800.719.4619 to arrange product return and replacement.

Please contact FallTech with any questions or concerns you may have regarding this notice or the procedures described in this notice. You can also contact FallTech via e-mail at service@falltech.com

4. ROOT CAUSE of the DEFECT

Inspections at FallTech have found snap hook products produced by YOKE Industrial Corp. in 2012 wherein one or more of the rivets used to secure the gate or back latch of the hook to the body of the hook may have been installed but not pressed to permanently hold the rivet in place. YOKE Industrial Corp. has stated that the un-pressed rivets are the result of infrequent random human error. This manufacturing defect may cause the un-pressed rivet to fall out of the hook and/or be pushed out of the hook. Using hooks with this defect may cause accidental disengagement or unfastening of the hook while it is in use; which could result in serious injury or death.

FallTech

1306 S. Alameda Street Compton, CA 90021,

USA Tel: 800-719-4619

Fax: 323-752-5613

www.falltech.com