Summary Statement

Tuckpointing creates some of the greatest exposures to silica in construction. This OSHA factsheet provides guidance on how to greatly reduce these exposures through the use of local exhaust ventilation.

February 2013

Controlling Silica Exposures in Construction While Doing Tuckpointing/ Mortar Removal

Silica is a mineral that is found in stone, soil and sand. It is also found in concrete, brick, mortar and other construction materials. Breathing in silica dust can cause silicosis, a serious lung disease. Using a handheld angle grinder to remove crumbling mortar between brick, stone and concrete blocks can result in hazardous levels of airborne silica. Tuckpointers’ silica exposures are among the highest in the construction industry. This fact sheet describes ways to reduce tuckpointers’ exposure to silica while using angle grinders to remove mortar.

Silica Dust Control Methods

Vacuum Dust Collection Systems

Vacuum dust collection systems (VDCSs) are one of the best ways to control dust while tuckpointing. A VDCS includes a shroud or hood which surrounds the grinding wheel, a vacuum, hose, and filter(s).

Remember to:

- Use a shroud appropriate for the grinder and wheel size.

- Use a vacuum with enough suction to capture dust at the point of grinding and removing mortar.

- Use a high-efficiency particulate air (HEPA) filter in the vacuum exhaust.

- Use a 1.5- to 2-inch diameter vacuum exhaust hose or a hose size that is recommended by the tool manufacturer.

- Use a static pressure gauge, where available, to monitor performance.

VDCSs work best when workers are properly trained and use good work practices. For best results:

- Keep the vacuum hose clear and free of debris, kinks and tight bends.

- Follow the equipment manufacturer’s directions on how to reduce dust buildup on the filter.

- Change vacuum-collection bags as needed.

- Set up a regular schedule for filter cleaning and maintenance.

- Avoid exposure to dust when changing vacuum bags and cleaning or replacing air filters.

Worker grinding without dust controls. Note the use of shielded Powered Air-Purifying Respirator. (Photo courtesy of CPWR).

Proper handling of the angle grinder is very important.

- Place one side of the shroud against the working surface before inserting the blade into the mortar joint. This directs the dust into the shroud as the blade cuts into the mortar joint.

- Keep the shroud tight against the working surface. This cuts down on dust that would otherwise escape from the collection system.

- Do not move the grinder back and forth along the slot as this will create a gap that increase dust escape. For better results, move the grinder in one direction, making a second pass only if necessary.

- Grind counter to the direction of blade rotation to minimize escaping dust.

- Back off the cutting pressure of the blade a short distance before removing it from the slot so the vacuum can have enough time to clear any dust buildup.

- Use only enough cutting force to operate the tool effectively and keep the leading tool edge flush against the working surface.

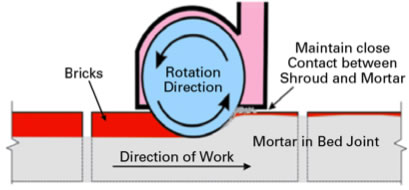

Do not leave a large gap between the shroud and uncut mortar. You can capture most of the dust generated from tuckpointing if you keep the shroud close to the uncut mortar (see Figure 1).

Figure 1: Minimizing the gap between the shroud and uncut mortar allows for good capture of crushed mortar coming off the blade. (Illustration courtesy of NIOSH).

Do not used compressed air to clean surfaces, clothing or filters because it can increase your exposure to silica. Clean only with a HEPA-filled vacuun or by wet methods.

Respiratory Protection

VDCSs can lower silica levels substantially; however, they generally do not reduce silica exposures to below regulatory limits. Therefore, most tuckpointing work will still require extra protection supplied by a respirator. Where respirators are required, employers have to put in place a written respiratory protection program in accord with OSHA’s Respiratory Protection standard. It must include the following:

- How to select a respirator;

- Fit testing;

- Directions on proper use, maintenance, cleaning and disinfecting;

- Medical evaluations of workers; and

- Training.

For more information on how to determine proper respiratory protection, visit OSHA’s web site at www.osha.gov.

For more detailed information on controlling silica exposures when tuckpointing, refer to OSHA Publication 3362, Controlling Silica Exposures in Construction.

This is one in a series of informational fact sheets highlighting OSHA programs, policies or standards. It does not impose any new compliance requirements. For a comprehensive list of compliance requirements of OSHA standards or regulations, refer to Title 29 of the Code of Federal Regulations.This information will be made available to sensory-impaired individuals upon request. The voice phone is (202) 693-1999; teletypewriter (TTY) number: (877) 889-5627.

For assistance, contact us. We can help. It's confidential.

![]()

U.S. Department of Labor

www.osha.gov

(800) 321-OSHA (6742)