The Potential for Beryllium Exposure from Abrasive Blasting Operations using Coal Slag: a Brief Summary of Research Conducted by CPWR

Summary Statement

From 2002‐2004, the CPWR - Center for Construction Research and Training set out to compare the potential for worker exposures to airborne toxics, particularly silica and metals, when abrasive blasting with three alternative abrasives (coal slag, steel grit, and specular hematite). Each summer during the study period, exposure sampling was conducted among painters abrasive blasting with one of the three abrasives on steel pedestrian bridges. Personal air monitoring was conducted for airborne respirable silica and metals concentrations by placing an air sampling device near the breathing zone of the workers. For this comparison study, samplers were placed outside of the supplied air respirators the workers were wearing. The authors found that the use of coal slag was associated with the highest amount of dust generation, but use of all three abrasives resulted in exposure to a range of metals including arsenic, cadmium, chromium, lead, manganese and nickel during all 3 repainting projects. For several of these metals, most notably lead, it was determined that their presence in the existing paint led to the levels detected in air samples. They also found elevated exposure to silica, which also was determined to result from the presence of silica in the existing paint, an unexpected finding. Another unexpected finding of our study was that beryllium exposure is a concern when abrasive blasting with coal slag.

January 30, 2013

Introduction

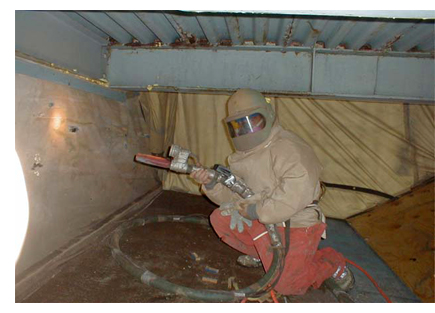

Abrasive blasting is a widely used technique for removing existing paint and rust from surfaces prior to applying new paint. Paint must be reapplied periodically and/or maintained to prevent rusting and failure of steel structures such as bridges. Paint is removed by propelling an abrasive agent under high pressure on coated surfaces, generating large amounts of inhalable, toxic dust. For new paint to bond effectively to steel, abrasive blasting must achieve a desired surface profile. Silica sand has been widely used as an abrasive in the past because of its low cost and ability to effectively remove paint whle leaving the desired surface profile. However, extremely high concentrations of respirable silica are generated that can lead to silicosis – an incurable and often deadly disease, autoimmune disorders, and possibly cancer. Use of sand is widely prohibited as an abrasive in the European Economic Community and by some state and federal agencies. NIOSH recommended a ban on the use of abrasives containing more than 1% silica in 1974 (NIOSH, 1974). Alternative types of abrasives include steel shot and grit, coal and metallurgical slags, and synthetic abrasives.

Abrasive blasting is a widely used technique for removing existing paint and rust from surfaces prior to applying new paint. Paint must be reapplied periodically and/or maintained to prevent rusting and failure of steel structures such as bridges. Paint is removed by propelling an abrasive agent under high pressure on coated surfaces, generating large amounts of inhalable, toxic dust. For new paint to bond effectively to steel, abrasive blasting must achieve a desired surface profile. Silica sand has been widely used as an abrasive in the past because of its low cost and ability to effectively remove paint whle leaving the desired surface profile. However, extremely high concentrations of respirable silica are generated that can lead to silicosis – an incurable and often deadly disease, autoimmune disorders, and possibly cancer. Use of sand is widely prohibited as an abrasive in the European Economic Community and by some state and federal agencies. NIOSH recommended a ban on the use of abrasives containing more than 1% silica in 1974 (NIOSH, 1974). Alternative types of abrasives include steel shot and grit, coal and metallurgical slags, and synthetic abrasives.

Center for Construction Research and Training Study

From 2002‐2004, the Center for Construction Research and Training (also known as “CPWR”) set out to compare the potential for worker exposures to airborne toxics, particularly silica and metals, when abrasive blasting with three alternative abrasives (coal slag, steel grit, and specular hematite). Each summer during the study period, exposure sampling was conducted among painters abrasive blasting with one of the three abrasives on steel pedestrian bridges being repainted by the New Jersey Department of Transportation. Personal air monitoring was conducted for airborne respirable silica and metals concentrations by placing an air sampling device near the breathing zone of the workers. For this comparison study, samplers were placed outside of the supplied air respirators the workers were wearing. Due to the high‐pressure blasting being performed in front of the workers, samplers were placed on the back of the blasting helmet in order to prevent sampler damage and/or failure.

Using task time‐weighted averages (TWAs) over the period of time spent blasting (approximately 2‐3 hours per shift), we found that the use of coal slag was associated with the highest amount of dust generation, but use of all three abrasives resulted in exposure to a range of metals including arsenic, cadmium, chromium, lead, manganese and nickel during all 3 repainting projects. For several of these metals, most notably lead, it was determined that their presence in the existing paint led to the levels detected in air samples. We also found elevated exposure to silica. This too was determined to result from the presence of silica in the existing paint, which was an unexpected finding.

Another unexpected finding of our study was that beryllium exposure is a concern when abrasive blasting with coal slag. We found beryllium was present at a concentration of 4 parts per million (ppm) in coal slag samples analyzed prior to blasting, and measured airborne beryllium concentrations of up to 9.5 μg/m3 during abrasive blasting tasks. The OSHA permissible exposure limit (PEL) for beryllium is 2 μg/m3 in air. The NIOSH recommended exposure limit (REL), which is health‐based as opposed to the OSHA PEL which also considers the technical and economic feasibility of controlling exposure, is 0.5 μg/m3. The ACGIH Threshold Limit Value (TLV), which is also health‐based and more recently updated, is 0.05 μg/m3. Based on these results, average exposures were almost 5 times the PEL and 19 times higher than the REL and TLV when coal slag was in use.

Implications

Beryllium is a human carcinogen that can affect the respiratory system and lead to chronic beryllium disease, which produces lung granulomas and scarring, following long‐term exposure to low concentrations. Exposure to low levels over time may also lead to sensitization (i.e., allergy), where once sensitized, individuals need to be exposed to only minute levels in order to cause adverse health effects. OSHA site inspections in addition to laboratory research conducted by NIOSH have also reported the potential for beryllium oveexposure when abrasive blasting with coal slag . In the past year, a number of producers of coal (and copper) slag abrasives have begun including beryllium on their product Material Safety Data Sheets (MSDS). However, it remains unclear whether MSDS disclosure of beryllium in these products is now universal.

Recommendations

The results of our study show that dry abrasive blasting in general is associated with the potential for exposure to a range of metals especially on painted surfaces. However, coal slag was the only abrasive associated with elevated beryllium contamination. Consideration should be given to using alternatives to coal slag, and, more generally, to dry abrasive blasting where possible for surface preparation. When this is not feasible, the use of full air‐supplied hoods as personal protective equipment (PPE) would be required with any of the abrasives used. However, even when accounting for a protection factor of up to 1,000, permissible exposures may still be exceeded especially for lead exposure when abrasive blasting lead‐containing paint.

For beryllium, sensitization (allergy) can result from very small amounts of exposure on the skin in addition to inhaling it into the lungs. Thus, it’s very important to have clean water and soap for hand washing and to maintain good hygiene and housekeeping practices on stes where present. Other metals, such as lead, cadmium and arsenic, are also systemic hazards that can adversely impact human health through multiple routes of exposure (inhalation, ingestion, dermal). These other metals have specific OSHA standards requiring workplace hygiene and housekeeping measures. These metals are likely to end up on work surfaces, tools, and clothing during abrasive blasting operations. In the absence of good workplace hygiene this can in turn result in the presence of the metals on skin, food, street clothes, in automobiles, etc. that can lead to exposure to the worker or even their families through “take‐home” exposures.

For more information and recommendations, please see the recent NIOSH Alert document, “Preventing Sensitization and Disease from Beryllium Exposure” (http://www.cdc.gov/niosh/docs/2011-107/pdfs/2011-107.pdf).

References

Bloomberg BNA, Right‐to‐Know Planning Guide Report. August 9, 2012. “Special Report: Some Companies Begin Listing Beryllium on Slag Data Sheets”. Bureau of National Affairs, Inc. Vol. 26, No. 16, Pages 61‐64.

Meeker JD, Susi P, Pellegrino A. 2005. Exposure to silica and metals among painters using specular hematite abrasive. Journal of Occupational and Environmental Hygiene, 2:D60‐D64.

Meeker JD, Susi P, Pellegrino A. 2006. Comparison of occupational exposures among painters using three alternative blasting abrasives. Journal of Occupational and Environmental Hygiene, 3:D80‐D84.

NIOSH. 2011. Preventing Sensitization and Disease from Beryllium Exposure. Department of Health and Human Services, National Institute for Occupational Safety and Health. Publication Number 2011‐107. http://www.cdc.gov/niosh/docs/2011-107/pdfs/2011-107.pdf

NIOSH. 1974. Criteria for a Recommended Standard: Occupational Exposure to Crystalline Silica. National Institute for Occupational Safety and Health. Publication Number 75‐120, page 10.

U.S. OSHA Guidance Document. 2006. Abrasive Blasting Hazards in Shipyard Employment. U.S. Department of Labor, Occupational Safety and Health Administration, Directorate of Standards and Guidance. http://www.osha.gov/dts/maritime/standards/guidance/shipyard_guidance.html