High Visibility Clothing For Heavy & Highway Construction

Summary Statement

Through the OSHA and Roadway Work Zone Safety and Health Partners Alliance, the American Road & Transportation Builders Association developed this brochure about high visibility clothing.

Workers Must Be Seen

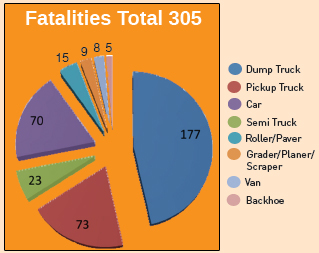

According to the U.S. Bureau of Labor Statistics (BLS), “The most common event associated with fatal occupational injuries incurred at a road construction site was worker struck by vehicle, mobile equipment. Of the 639 total fatal occupational injuries at road construction sites during the 2003–07period, 305 were due to a worker being struck by a vehicle or mobile equipment.” The BLS article further reports that more workers are struck and killed by construction equipment (38 percent) than by cars, vans and tractor-trailers (33 percent). As such, work zone “runovers” and “backovers” are clearly the greatest hazard to roadway construction workers and, by far, the leading cause of death.

The use of high visibility clothing is one important strategy in reducing the number of “struck-by” deaths on road construction sites.

High Visibility Clothing

For Heavy & Highway Construction

Standards and Regulations

Several agencies of the federal U.S. government have specific standards and guidance with regards to the wearing of high visibility clothing, including the Occupational Safety and Health Administration and the Federal Highway Administration. These agencies most commonly reference an industry consensus standard issued by the International Safety Equipment Association (ISEA) and the American National Standards Institute (ANSI). This is known as the ANSI/ISEA 107 Standard or “American National Standard for High Visibility Safety Apparel and Headwear.”

ANSI/ISEA 107

This standard provides performance criteria for the materials to be used in high visibility PPE, specifies minimum areas and, where appropriate, recommends placement of the materials. Performance requirements focus on the color and brightness of garments and headwear relative to the work environment and the combined use of fluorescent and retroreflective materials to make a person conspicuous in all light conditions, day and night. The standard offers three Performance Classes for garments, based on worker hazards and tasks, complexity of the work environment or background and vehicular traffic and speed conditions.

ANSI A10

ANSI A10.47 Work Zone Safety for Highway Construction “High Visibility Safety Apparel.” Garments and headwear worn by workers to provide increased conspicuity and visibility and that meet the performance requirements contained in ANSI/ISEA 107.

Visibility. Flagger visibility shall be enhanced through appropriate positioning and the use of Class 2 high-visibility safety apparel during daytime activity and Class 3 high-visibility safety apparel during nighttime activity in compliance with ANSI/ISEA 107, High Visibility Safety Apparel and Headwear.

U.S. Federal Highway Administration

Manual on Uniform Traffic Control Devices (MUTCD) 6D.03 (2009): All workers, including emergency responders, within the right-of-way who are exposed either to traffic (vehicles using the highway for purposes of travel) or to work vehicles and construction equipment within the TTC zone shall wear high-visibility safety apparel that meets the Performance Class 2 or 3 requirements of the ANSI/ISEA 107–2004 publication entitled “American National Standard for High-Visibility Safety Apparel and Headwear” or equivalent revisions, and labeled as meeting the ANSI 107-2004 standard performance for Class 2 or 3 risk exposure... A person designated by the employer to be responsible for worker safety shall make the selection of the appropriate class of garment.

OSHA

OSHA Letter of Interpretation #20080829-8611 (July 23, 2009): “ . . . high visibility apparel is required under the General Duty Clause to protect employees exposed to the danger of being struck by public and construction traffic while working highway/road construction zones. Typically, workers in a highway/work zone are exposed to that hazard most of the time.”

|

|

|

|---|---|---|

Class I Vest: Not acceptable for road construction work. |

Class II Vest: Most commonly used in construction. |

Class III Ensemble: For low-light and high-hazard conditions. |

High Visibility Clothing Defined

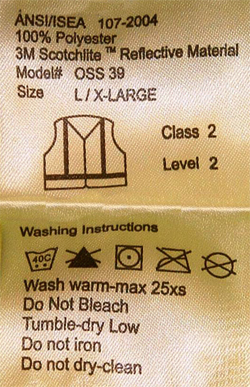

High visibility garments can be defined as clothing designed to make the wearer more visible—particularly to vehicular traffic— and contain design properties making the wearer discernible against their work environment. They are considered personal protective equipment (PPE) in the work environment. High visibility clothing will carry an ANSI/ISEA label explaining garment characteristics including the name, trademark, or other means of identifying the manufacturer or authorized representative; a designation of the product type or commercial name; the number of this specific ANSI/ISEA standard (ANSI/ISEA 107); a pictogram showing the garment Class and Level of performance for the retroreflective material, and care labeling.

High visibility garments generally have two design criteria: background fabric and retroreflective tape. The garment is composed primarily of a high-quality fluorescent fabric in colors including fluorescent yellow/green, fluorescent orange-red and fluorescent red. Retroreflective tape is added to areas such as the arms, torso and waist so as to identify the wearer as a “person” as opposed to a traffic control device such as a drum or sign. The fluorescent fabric is used to make the wearer more visible in daylight hours, particularly in twilight conditions. The retroreflective tape makes the wearer more visible at night and during lowlight conditions as the tape reflects back light from motorists’ headlights. While vests are convenient, recent research has concluded that garments with high visibility material on the ends of the limbs are the most effective way to enhance nighttime conspicuity.

In the United States, most government agencies and private organizations rely upon the ANSI/ISEA 107 Standard for criteria specifying acceptable designs for high visibility garments. For roadway construction workers, only ANSI/ISEA Class II and Class III garment are acceptable.

The ANSI/ISEA 107-2010 standard provides explanations as to when each type of garment should be used:

Class 1 Garments

Work permits undivided attention to traffic and there is ample separation between worker and motor vehicles. Background is not complex and vehicle/equipment speeds do not exceed 25 mph. (Examples: parking attendants, warehouse workers, workers on sidewalks) Note: ANSI/ISEA 107 Class 1 garments do not provide compliance with 2009 MUTCD highway worker regulations.

Class 2 Garments

For work in inclement weather and/or areas with complex backgrounds. Worker’s attention may be diverted from approaching traffic or worker is in closer proximity to traffic. Vehicles and equipment travel at speeds greater than those specified for Class 1. (Examples: roadway construction workers, utility workers, survey crews.) These are guidelines for assessing conditions; other variables may apply.

For work in inclement weather and/or areas with complex backgrounds. Worker’s attention may be diverted from approaching traffic or worker is in closer proximity to traffic. Vehicles and equipment travel at speeds greater than those specified for Class 1. (Examples: roadway construction workers, utility workers, survey crews.) These are guidelines for assessing conditions; other variables may apply.

Class 3 Garments

For workers exposed to high speed traffic and/or conditions where visibility of workers may be reduced. For conditions where equipment operators perform tasks near pedestrian workers. Worker must be conspicuous through a full range of body motions at a minimum of 1,280 feet and identifiable as a person. (Examples: flaggers, roadway construction workers, utility workers, survey crews, emergency responders).

For workers exposed to high speed traffic and/or conditions where visibility of workers may be reduced. For conditions where equipment operators perform tasks near pedestrian workers. Worker must be conspicuous through a full range of body motions at a minimum of 1,280 feet and identifiable as a person. (Examples: flaggers, roadway construction workers, utility workers, survey crews, emergency responders).

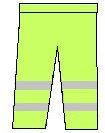

Class E Garments

The combination of a Class 2 (or 3) vest with Class E pants or shorts creates a Performance CLass 3 ensemble. A possible use for this ensemble would be wearing a Class II vest during daylight hours, and adding the pants during night operations to create a Class III garment.

The combination of a Class 2 (or 3) vest with Class E pants or shorts creates a Performance CLass 3 ensemble. A possible use for this ensemble would be wearing a Class II vest during daylight hours, and adding the pants during night operations to create a Class III garment.

Unclassified Garments

Be careful to select clothing that meets ANSI/ISEA 107 Standards. There are a number of products on the market that appear similar to ANSI garments, but are made of inferior materials and do not provide sufficient visibility, durability and protection.

Be careful to select clothing that meets ANSI/ISEA 107 Standards. There are a number of products on the market that appear similar to ANSI garments, but are made of inferior materials and do not provide sufficient visibility, durability and protection.

Read the Label

When purchasing and selecting high visibility clothing, be sure to look at the label. It will include information about class, standards compliance, and care instructions.

Be careful when using high visibility vests when performing some operations if other hazards are present. This vest caught fire from sparks when worn by a worker while grinding. Be sure to specify proper attributes, like fire resistance when necessary, in your PPE. Loose vests can also become caught in moving equipment.

While in relatively good condition, this vest has become faded from excess washing and/or sun exposure and has lost its fluorescent value. It should be replaced.

This vest is no longer serviceable as it is very dirty negating the retroreflective and fluorescent properties. Some of the retroreflective tape is torn and does not outline the wearer as a “person.”

Proper Wear

Garments should be worn properly, meaning they should be the right size for the person wearing it. Vests and jackets should be kept closed on the front and sides to ensure visibility from 360 degrees. Because of minimum requirements for amounts of background and retroreflective materials, care should be taken when purchasing garments for workers with a small build to ensure their garments meet the minimum requirements. Garments should not be modified so as to void the class certification.

Garments should be kept in good, clean condition and replaced when worn or dirty so as to preclude their function as high visibility clothing.

References

Monthly Labor Review, “Fatal Occupational Injuries at Road Construction Sites 2003-2007”Pegula, Stephen

Bureau of Labor Statistics

Washington, DC

November 2010

American National Standards Institute/International Safety Equipment Association,

ANSI/ISEA 107

“American National Standard for High-Visibility Safety Aparel and Head Wear”

Arlington, VA

1999 (rev. 2004, 2010)

Through the OSHA and Roadway Work Zone Safety and Health Partners Alliance, the American Road & Transportation Builders Association developed this brochure for informational purposes only. It does not necessarily reflect the official views of OSHA or the U.S. Department of Labor.