Summary Statement

This study explores fall hazards at a commercial construction site, focusing on carpenters, electricians, ironworkers, painters and roofers, while utilizing the GW Audit of Fall Risk assessment tool. It evaluated the fall prevention practices for five different phases of construction (concrete pouring/placement, skin, interior rough-in, interior finishes, roofing), four different types of equipment (ladders, mobile scaffolding, personal fall arrest equipment, aerial lifts), and three types of worksite elements (guardrails, scaffolding, and roof sheathing).

SECTION 1

A unique opportunity to study fall hazards in commercial construction

The Opportunity

Researchers visited the construction site

38

times between April 2013 and March 2014.

Researchers at The George Washington University Milken Institute School of Public Health recognized that they had a rare opportunity when the university made the decision to construct a new building to house the school on the university’s Foggy Bottom campus in Washington, D.C. The occupational health and construction safety experts in the school’s Department of Environmental and Occupational Health understood that the project presented the chance to use the construction site as a “living laboratory.” Their research showed that fall hazards in commercial construction had received much less attention than in residential construction.

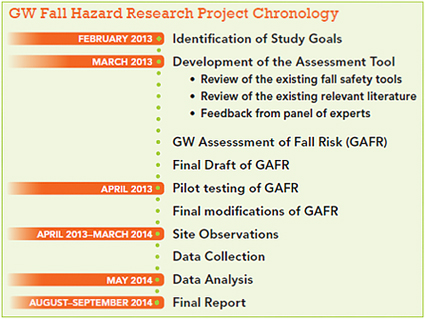

A team led by Melissa Perry, Professor and Chair of the school’s Department of Environmental and Occupational Health, created a new assessment tool, the GW Audit of Fall Risks (GAFR), to aid in the study. This assessment instrument is designed to collect information about the use of equipment at construction sites including guardrails, scaffolding, ladders, aerial lifts , and safety harnesses. It enables researchers to assess whether the equipment is being used in accordance with the safety guidelines established by the Occupational Safety and Health Administration (OSHA).

GW researchers used the GAFR tool to make systematic observations of worker- and worksite-level fall prevention practices throughout different phases of the new building’s construction from April 2013 to March 2014. The building officially opened in May 2014.

The study was made possible by a partnership between the university and the general contractor for the project, The Whiting-Turner Contracting Company. CPWR, the Center for Construction Research and Training, funded the creation of this manual to raise awareness about fall hazards in commercial construction.

Why Study Fall Prevention?

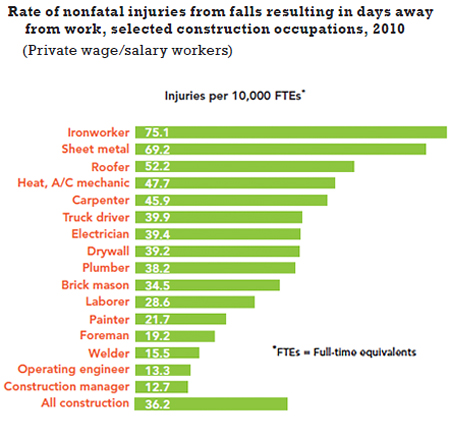

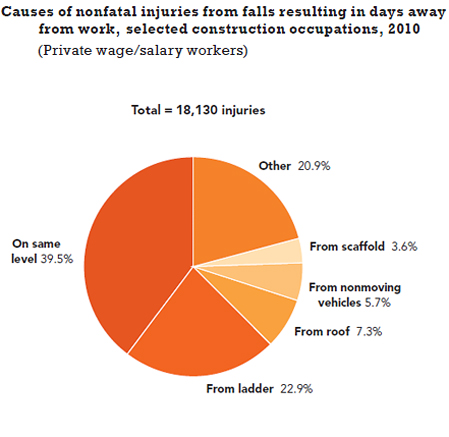

Falls are one of the leading causes of workplace death, lost work time, and costs to industry, particularly in construction. In fact, falls are the construction industry’s number one cause of fatal injuries, according to the Occupational Safety and Health Administration (OSHA). In 2010, falls accounted for about one-third of construction fatalities. They are also a major cause of construction workplace injuries. When the construction industry is cited for OSHA standard violations, it is frequently for issues with fall protection (29 Code of Federal Regulations 1926.10), general scaffolding (29 CFR 1926.451), and ladder (29 CFR 1926.1053) requirements, according to fiscal year 2013 OSHA data.

The above graph and chart were created

by CPWR using U.S. Bureau of Labor Statistics data

Focus on Risks to Groups of Tradespeople and Differing Construction Phases

The GW study is unique in its approach of simultaneously assessing worksite- and individual-level fall prevention practices. The researchers focused on hazards and compliance with fall safety practices related to the use of ladders, aerial lifts, scaffolding, and personal fall arrest equipment among five construction trades documented to be at high risk of falling: electricians, painters, carpenters, ironworkers (including welders and window glazers), and roofers. The graph and chart above suggest that workers in these trades experience falls at a concerning rate.

The GW study is unique in its approach of simultaneously assessing worksite- and individual-level fall prevention practices. The researchers focused on hazards and compliance with fall safety practices related to the use of ladders, aerial lifts, scaffolding, and personal fall arrest equipment among five construction trades documented to be at high risk of falling: electricians, painters, carpenters, ironworkers (including welders and window glazers), and roofers. The graph and chart above suggest that workers in these trades experience falls at a concerning rate.

The Study Tool: GW Assessment of Fall Risks (GAFR)

The GW Audit of Fall Risks (GAFR) assessment instrument developed by the researchers in the Milken Institute School of Public Health’s Department of Environmental and Occupational Health was used to conduct the study of fall hazards in commercial construction as the new building was being constructed. The GAFR was developed based on a review of OSHA standards and relevant literature, as well as three existing assessment tools. (See Appendix C for more details.)

The tool enables users to systematically observe the condition and use of equipment known to increase the likelihood of worker injuries at the site. A printable version of the tool’s list is available at http://www.elcosh.org/.

Study Results in a Nutshell

Study Results in a Nutshell

The safety record of this construction project was excellent, as no accidents resulted from a fall of 6 feet or higher. Even so, the study did identify opportunities to improve on safety.

- The safety compliance issues seen most frequently were the use of mobile scaffolds without locking the wheels and the improper use of safety harnesses—or the omission of their use.

- The researchers also observed improper climbing techniques on ladders, including working from the top rung, climbing with tools in hand, and the inappropriate choice of ladders.

- During the construction process, the researchers documented damaged or absent sections of wooden guardrails.

- The highest prevalence of issues was documented during the skin and interior rough-in phases.

- Ironworkers and electricians are at the highest risk of falling because they work at high elevations most frequently.

SECTION 2

Controlling fall hazards at a commercial construction site

Fall Hazard Definitions

According to OSHA, a fall hazard is “anything at your worksite that could cause a worker to lose his balance or lose bodily support and result in a fall.” Almost any walking or working surface at a construction site has the potential of being a fall hazard, especially when it is elevated four feet or higher off of the ground. In OSHA’s revised construction industry safety standards (29 CFR, Subpart M, Fall Protection, 1926.500, 1926.501, 1926.502, and 1926.503), the threshold for a fall hazard is six feet; therefore, protection must be provided for workers who are operating at elevations six feet or higher off of the base surface.

Major Types of Fall Hazards

OSHA’s records show the major types of fall hazards in a general construction setting are:

- Unprotected roof edges, roof and floor openings, structural steel beams creating leading edges, etc.

- Improper scaffold construction

- Unsafe portable ladders

Why This Study Was Conducted

To the knowledge of the authors, commercial building construction has not been the subject of any recent fall study. In addition, no previous study on any type of site has sought to simultaneously assess worksite- and individual-level fall prevention practices. The specific aims of this study were developed based on the major findings of existing literature on construction safety and the gaps within this research. (See Appendix B for more details.)

Data Collection

Milken Institute School of Public Health Research Assistant Amanda McQueen administered the GAFR assessment tool weekly from April 2013 to March 2014, accompanied by the site safety manager/superintendent, evaluating fall prevention safety practices for the following (see Appendix A for further definitions):

- Five trades of interest (carpenters, electricians, ironworkers, painters, and roofers)

- Five different phases of construction (concrete pouring/placement, skin, interior rough-in, interior finishes, roofing)

- Four types of equipment (ladders, mobile scaffolding, personal fall arrest equipment, aerial lifts)

- Three types of worksite elements (guardrails, scaffolding, and roof sheathing)

Use of the GAFR Tool

The Milken Institute School of Public Health researchers designed the GAFR assessment tool in a checklist format to collect information about each site visit. Research auditors using the tool begin by evaluating the condition of more static elements of the worksite, such as guardrails and scaffolding. From there, the tool helps auditors assess specific pieces of equipment used while workers are elevated, such as ladders, harnesses, and aerial lifts. The instrument includes guidelines for evaluating whether workers are following the list of criteria that OSHA guidelines stipulate must be met for each piece of equipment to be considered “safe for use.” Th e auditor can track instances of “unsafe work practices” by recording the floor number, worker hard-hat number (for anonymous identifi cation), and additional details about any criteria that are not met.

SECTION 3

Findings, observations, and conclusions

The overall level of worker compliance with fall safety requirements, as observed by the GW researchers, for the construction project was over 95%. However, the observed instances demonstrating a potential for fall risk were noteworthy. The majority of these instances resulted from situations where workers neglected to either readjust current equipment, to obtain a more suitable piece of equipment, or to modify their working habits for safety purposes in order to work more efficiently. The GW researchers observed some instances where workers continued to work unsafely after the site superintendent instructed them to take steps to increase their safety (for example, working from the top rung of a ladder instead of retrieving a more suitable one).

The overall level of worker compliance with fall safety requirements, as observed by the GW researchers, for the construction project was over 95%. However, the observed instances demonstrating a potential for fall risk were noteworthy. The majority of these instances resulted from situations where workers neglected to either readjust current equipment, to obtain a more suitable piece of equipment, or to modify their working habits for safety purposes in order to work more efficiently. The GW researchers observed some instances where workers continued to work unsafely after the site superintendent instructed them to take steps to increase their safety (for example, working from the top rung of a ladder instead of retrieving a more suitable one).

Ladders. GW researchers observed ladders in use 156 times. Of these, two were extension ladders, three were job-made, and the remaining 151 were portable. Electricians were the workers most oft en observed using ladders, and they were the group most oft en seen climbing and working from ladders in unsafe ways, followed by carpenters and painters. Although work with ladders took place during every phase of construction, the bulk of the work requiring ladders was completed during the skin, interior rough-in, and roofing phases, during which the potential for fall hazards increased.

| Ladders |

|

|---|---|

| Aerial Lifts |

|

| Personal Fall Arrest |

|

Lifts. During the research project, GW researchers observed aerial scissor and boom lifts in use 46 times, primarily by ironworkers during the skin and interior rough-in phases. However, the issues involving the improper use of personal fall protection equipment occurred when carpenters and electricians were using this equipment.

Personal Fall Arrest Equipment. The majority of the 94 pieces of personal fall arrest equipment observed in use were by ironworkers and carpenters during the skin and interior rough-in phases. The level of compliance with requirements for proper use of this equipment was lower than for either ladders or lifts. Most of the instances of fall risk occurred due to a worker using the personal fall arrest system incorrectly, such as tying off too far from the area of work, not wearing the harness correctly, or not using one at all. The main types of personal fall arrest systems observed in use were retractable harnesses and harnesses with lanyards. These two harness types were used improperly most frequently.

Personal Fall Arrest Equipment. The majority of the 94 pieces of personal fall arrest equipment observed in use were by ironworkers and carpenters during the skin and interior rough-in phases. The level of compliance with requirements for proper use of this equipment was lower than for either ladders or lifts. Most of the instances of fall risk occurred due to a worker using the personal fall arrest system incorrectly, such as tying off too far from the area of work, not wearing the harness correctly, or not using one at all. The main types of personal fall arrest systems observed in use were retractable harnesses and harnesses with lanyards. These two harness types were used improperly most frequently.

Guardrails. During the construction project, guardrails were in place to provide fall protection on each of the nine floors and roof. These guardrails were observed 252 times during the project. Overall, the use and structural quality of the wooden and wire rope guardrails was compliant with OSHA guidelines. In cases where portions of the guardrails, such as the toeboards, were missing or damaged, repairs were made immediately.

Scaffolding. This equipment was observed on every floor and on the roof during every site visit. The majority of the 96 recorded observations were of fixed scaffolding, but the most frequently occurring issues, overall, were instances where workers used mobile scaffolds without first locking the wheels to prevent the equipment from moving. Although observed less often, another issue resulting in the increased risk of falling was the lack of proper railings on a mobile scaffold. According to observer notes, carpenters were the most common users of mobile scaffolds during the skin and interior rough-in phases.

| Guardrails |

|

|---|---|

| Scaffolding |

|

| Roof Sheathing |

|

Roof sheathing. Although no issues were seen, installation of sheathing was only observed during the first six site visits.

Observations

GW researchers made specific observations of skilled trade workers at the construction site. Carpenters were most often observed using ladders and personal fall arrest equipment. Their increased risk of falling resulted mainly from the improper use of personal fall arrest equipment. The researchers also made many observations of electricians using ladders. The safety issue observed most frequently for this group was working from the top two rungs of a ladder, often because it was not the correct height.

GW researchers made specific observations of skilled trade workers at the construction site. Carpenters were most often observed using ladders and personal fall arrest equipment. Their increased risk of falling resulted mainly from the improper use of personal fall arrest equipment. The researchers also made many observations of electricians using ladders. The safety issue observed most frequently for this group was working from the top two rungs of a ladder, often because it was not the correct height.

Ironworkers were frequently observed using all three types of equipment, particularly personal fall arrest equipment. Due to the nature of the work of welders and window glazers, they were most commonly found working unsafely over ledges or platforms. Increased risk of falling among this group mainly resulted from not tying personal fall protection systems to a structurally-sound tie-off point or not using the system at all.

The workers observed least frequently were painters and roofers. They were primarily observed during the interior rough-in/interior finishes and roofing stages, respectively. Workers from both trades were most commonly observed using ladders, with the most frequent instance of increased fall risk resulting from climbing up and down the ladder with tools in hand, and therefore not maintaining three points-of-contact.

| Carpenters | Total of 68 observations

|

|---|---|

| Scaffolding | Total of 95 observations

|

| Ironworkers | Total of 96 observations

|

| Painters | Total of 32 observations

|

| Roofers | Total of 5 observations

|

The main worksite issues observed by GW researchers during the project were with mobile scaffolding. Many of the workers using this scaffolding were puzzled when asked by the construction supervisor what was wrong with their set-ups. These problems were almost always due to the wheels being unlocked while in use.

Field Notes and Anecdotes

The average duration of each site visit by GW researchers was 60 minutes spent going through each of the building’s nine floors (including two basements). Although there was no evidence of specific actions taken against a particular worker, many of the scaffolding and ladder usage issues were attributable to the same workers during certain periods of the project. Noting this, the site superintendent made it clear to these workers’ foreman that additional supervision or training was needed.

Mid-way through the project, the site superintendent stopped the work entirely in order to conduct an all-hands training session focused on the proper use of ladders, scaffolding, personal fall arrest equipment, and other issues linked to safety compliance. It was inspired by having workers sent home for safety violations, resulting in lost work time and decreased productivity.

The tasks performed by ironworkers typically involved accessing difficult-to-reach locations while using bulky equipment. Therefore, they would more frequently have to make compromises in order to effectively complete their tasks.

Conclusions

Workers are under constant productivity pressure, which can make it difficult to conduct their work safely despite their best intentions. Whiting-Turner’s supervisor for the project, Mike Whitmore, worked hard to uphold safety standards. He ably demonstrated his ability to keep safety concerns on the minds of his company’s contractors. However, the GW researchers observed some notable unsafe practices, and there was some room for improvement.

Workers are under constant productivity pressure, which can make it difficult to conduct their work safely despite their best intentions. Whiting-Turner’s supervisor for the project, Mike Whitmore, worked hard to uphold safety standards. He ably demonstrated his ability to keep safety concerns on the minds of his company’s contractors. However, the GW researchers observed some notable unsafe practices, and there was some room for improvement.

Even though high safety standards were maintained throughout the construction project, fall hazards still occurred. No accidents resulted from a fall from six feet or higher during the entirety of the project. The worksite provided adequate fall protection for workers throughout the entirety of the project, with over Conclusions Workers are under constant productivity pressure, which can make it difficult to conduct their work safely despite their best intentions. Whiting-Turner’s supervisor for the project, Mike Whitmore, worked hard to uphold safety standards. He ably demonstrated his ability to keep safety concerns on the minds of his company’s contractors. However, the GW researchers observed some notable unsafe practices, and there was some room for improvement.

Even though high safety standards were maintained throughout the construction project, fall hazards still occurred. No accidents resulted from a fall from six feet or higher during the entirety of the project. The worksite provided adequate fall protection for workers throughout the entirety of the project, with over 95% compliance. Even so, the wheels of mobile scaffolds were not always locked while the equipment was in use. Guardrails are subject to a great deal of wear and tear during construction projects, and some sections of the site’s wooden guardrails, primarily the toeboards, were damaged or absent entirely. Fall protection equipment was used most heavily during the skin and interior rough-in phases, but noncompliance was also frequently observed during those phases.

Project Principal Investigator Dr. Melissa Perry, Site Superintendent Mike Whitmore, and

Student Researcher Amanda McQueen at the construction site.

The results of this study suggest that tasks involving the use of personal fall arrest equipment should be monitored to ensure proper use, with a particular focus on ironworkers. Consistent training and reminders to workers about the proper utilization of equipment are likely to help reduce the potential for falls on commercial construction sites and, thus, potential for injury due to falls.

Taken together, the observations reflect the reality that fall prevention requires constant vigilance on the part of everyone at a worksite. These observations reinforce that achieving high construction safety requires proper design, a strong safety culture, and supportive worker training.

APPENDICES

Appendix A: Definitions

Appendix A: Definitions

EQUIPMENT

Ladder

Portable Ladder = a ladder that can be readily moved or carried.

Extension Ladder = a non-self-supporting portable ladder adjustable in length, consisting of two or more sections traveling in guides or brackets so arranged as to permit length adjustment.

Job-Made Ladder = a ladder that is fabricated by employees, typically at the construction site, and is not commercially manufactured.

Aerial Lift

Boom Lift = an aerial device (except ladders) with a telescopic or extensible boom.

Scissor Lift = although not technically a type of aerial lift, these are any lift with platforms that extend beyond the equipment’s wheelbase.

Personal Fall Arrest [System]

Lanyard = a flexible line or rope, wire rope, or strap which is used to secure the body belt or body harness to a deceleration device, lifeline, or anchorage.

Lifeline = a component consisting of a flexible line for connection to an anchorage at one end to hang vertically (Vertical Lifeline), or for connection to anchorages at both ends to stretch horizontally (Horizontal Lifeline), and which serves as a means for connecting other components of a personal fall arrest system to the anchorage.

Retractable Lifeline/Lanyard = a deceleration device which contains a drum wound line which may be slowly extracted from, or retracted onto, the drum under slight tension during normal employee movement, and which, after onset of a fall, automatically locks the drum and arrests the fall.

Guardrail

Wooden = most common among inner and outer regions of the building.

Wire rope = commonly used around outer perimeter of each floor.

Scaffolding

Mobile = a powered or unpowered, portable, caster or wheelmounted supported scaffold.

Fixed/System = a scaffold consisting of posts with fixed connection points that can be interconnected at predetermined levels.

Suspension = one or more platforms suspended by ropes or other non-rigid means from one overhead structure(s).

Roof Sheathing = any stiff sheet material, such as plywood or boarding, laid above rafters or trusses as a base for roofing material.

PHASE

Concrete Placement = the laying, pouring, or pumping of fresh concrete into formwork, molds, excavations, etc., to attain its final shape.

Skin = method of construction of walls, floors, and panels in which boards or membranes are fixed to either side of a frame or series of structural members as bracing.

Interior Rough In = the laying out of basic infrastructure without covering materials (walls, ceilings, flooring) and without making electrical or plumbing connections.

Roofing = the placement of impermeable surface and finish material that provides waterproof and weatherproof protection for roof.

Interior Finishes = the final treatment, layer of material, or coating for an interior surface or component.

TRADES

Carpenter = worker who performs carpentry tasks, including interior and exterior finishes.

Electrician = worker who installs electrical systems.

Ironworker = worker who performs ironworking tasks, including welding and window-glazing.

Painter = worker who applies primer, paint, putty, and any other substance to walls, ceilings, or floors.

Roofer = worker who performs roofing tasks, including the installation of roof sheathing.

Appendix B: Why This Study Was Conducted

To the knowledge of the researchers, no previous study has sought to assess worksite- and individual-level fall prevention practices simultaneously. Therefore, the specific aims of this study were developed based on the major findings of existing literature on construction safety and the gaps within this research:

Specific Aim I: To quantify trade-level hazards and compliance with fall safety practices related to ladder, aerial lift, and personal fall arrest use among five construction trades: electricians, painters, carpenters, welders, and roofers; and to determine whether there are differences among these trades.

- Researchers of a Harvard University study developed an assessment tool to assess individual-level stepladder safety practice.

– Is renovation riskier than new construction? An observation comparison of risk factors for stepladder-related falls published in the American Journal of Industrial Medicine (Ronk et al., 2011)

-

Analysis of contributing factors of fall injuries among union carpenters over a three-year period using an active injury surveillance system to interview individual injured workers and the incident location.

– Falls in residential carpentry and drywall installation: findings from active injury surveillance with union carpenters published in the Journal of Occupational and Environmental Medicine (Lipscomb et al., 2003)

-

Additional surveillance studies considering specific construction trades, such as electricians, painters, and carpenters, as differing in their risks of falling.

– Mortality among North Carolina construction workers, 1988-1994 published in Applied Occupational and Environmental Hygiene (Wang, 1999)

– Fatal falls in the US construction industry, 1990 to 1999 published in the Journal of Occupational and Environmental Medicine (Derr et al., 2001)

– Fatal falls among Hispanic construction workers published in Accident Analysis & Prevention (Dong et al., 2009)

Specific Aim II: To quantify worksite-level fall prevention practices related to scaffolding, guardrails, safety nets, and roof sheathing across different construction phases (i.e., concrete placement, skin, interior rough-in, interior finishes, and roofing).

- A Washington University construction safety team based in St. Louis, MO developed a tool to assess fall hazards and control practices in residential construction sites based on OSHA’s fall prevention standards for residential construction.

– Development of the St. Louis audit of fall risks at residential construction site published in the International Journal of Occupational and Environmental Health (Kaskutas et al., 2008)

-

Researchers at West Virginia University developed an audit tool to assess fall safety practice in general construction and administered the tool quarterly to evaluate the impact of their organization intervention on improvement of fall prevention practice.

– Prevention of construction falls by organizational intervention published in Injury Prevention (Becker et al., 2001)

-

Harvard University studies developing an assessment tool for ladders and evaluating safety inspection data collected from Harvard University-owned construction projects.

– Portable ladder assessment tool development and validation

– Quantifying best practices in the field published in Safety Science (Dennerlein et al., 2009)

– Preventing falls from ladders in construction, Harvard University (Perry & Ronk, 2010)

– Determining safety inspection thresholds for employee incentives programs on construction sites published in Safety Science (Sparer & Dennerlein, 2013)

Appendix C: Development of the GW Audit of Fall Risks (GAFR) Assessment Instrument

The GW Audit of Fall Risks (GAFR) assessment instrument was developed using the following process:

- Review of OSHA standards and relevant literature, as well as three existing assessment tools to develop an extensive list of items to assess fall safety practices in general construction:

– Fall safety assessment tool for general construction (Dennerlein et al., 2009)

– St. Louis Assessment of Fall Risks tool for residential construction (Kaskutas et al., 2008)

– Ladder assessment tool from the Harvard University studies (Perry & Ronk, 2010)

-

Review of this list by an expert panel, including on-site safety superintendents, for feedback on usability and inclusion of appropriate fall safety assessment criteria

-

Two-week Pilot test using the newly drafted instrument to determine areas for improvement and refinement

Appendix D: References

Becker, P., Fullen, M., Akladios, M., & Hobbs, G. (2001). Prevention of construction falls by organizational intervention. Injury Prevention Supplemental, 7, 64-67

The Center for Construction Research and Training [CPWR]. (2013). Safety culture and climate in construction: bridging the gap between research and practice workshop report. Retrieved from https://www.cpwr.com/sites/default/files/publications/CPWR_Safety_Culture_Final_Report_0.pdf

The Center for Construction Research and Training [CPWR]. (2013). Chartbook: fatal and nonfatal injuries. Retrieved from http://www. cpwr.com/publications/chartbook-fatal-and-nonfatal-injuries

Courtney, T. K., Matz, S., & Webster, B.S. (2002). Disabling occupational injury in the US construction industry, 1996. Occupational and Environmental Medicine, 44(12), 1161-1168

Davies, N., & Jokiniemi, E. (2008). Dictionary of architecture and building construction. Burlington, MA: Elsevier Ltd.

Dennerlein, J. T., Ronk, C.J., & Perry, M.J. (2009). Portable ladder assessment tool development and validation – quantifying best practices in the field. Safety Science, 47(5), 636-639

Derr, J., Forst, L., Chen, H.Y., & Conroy, L. (2001). Fatal falls in the US construction industry, 1990-1999. Occupational and Environmental Medicine, 43(10), 853-860

Dong, X. S., Fujimoto, A., Ringn, K., & Men, Y. (2009). Fatal falls among Hispanic construction workers. Accident Analysis & Prevention, 41(5), 1047-1052

Hsiao, H., & Simeonov, P. (2001). Preventing falls from roofs: a critical review. Ergonomics, 44, 537–61

Kaskutas, V., Dale, A.M., Lipscomb, H.J., Gaal, J., Fuchs, M., & Evanoff, B.A. (2010). Fall prevention among apprentice carpenters. Scandinavian Journal of Work, Environment & Health, 36(3), 258-265

Kaskutas, V. K., Dale, A.M., Lipscomb, H.J., Evanoff, B.A. (2008). Development of the St. Louis audit of fall risks at residential construction sites. International Journal of Environmental Health, 14(4), 243-249

Leamon, T.B., & Murphy, P.L. (1995). Occupational slips and falls: more than a trivial problem. Ergonomics, 38(3), 487-498

Lehtola, M.M., Van Der Molen, H.F., Lappalainen, J., Hoonakker, P.L.T., Hsiao, H., Haslam, R.A., Hale, A.R., & Verbeek, J.H. (2008). The effectiveness of interventions for preventing injuries in the construction industry—a systematic review. American Journal of Preventive Medicine, 35, 77–85

Lipscomb, H.J., Glazner, J.E., Bondy, J., Guarini, K., & Lezotte, D. (2006). Injuries from slips and trips in construction. Applied Ergonomics, 37, 267–74

Occupational Safety & Health Administration [OSHA]. (1996). Fall protection: construction safety and health outreach program. Retrieved from https://www.osha.gov/doc/outreachtraining/htmlfiles/subpartm.html

Occupational Safety & Health Administration [OSHA]. (1996). Regulations (Standards-29 CFR 1915.151). Retrieved from https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_ table=STANDARDS&p_id=10267

Occupational Safety & Health Administration [OSHA]. (2002). OSHA standard interpretation letter. ANSI/SIA A92.3, A92.5, and A92.6. Retrieved from https://www.osha.gov/SLTC/etools/shipyard/standard/ scaffold/scissor_lifts.html

Occupational Safety & Health Administration [OSHA]. (2003). Stairways and ladders: a guide to OSHA rules. 3124-12R 2003. Retrieved from https://www.osha.gov/Publications/ladders/osha3124.html

Occupational Safety & Health Administration [OSHA]. (2010). Regulations (Standards-29 CFR 1910.21). Retrieved from https:// www.osha.gov/pls/oshaweb/owadisp.show_document?p_id=9713&p_ table=STANDARDS

Occupational Safety & Health Administration [OSHA]. (2010). Regulations (Standards-29 CFR 1926.450). Retrieved from https://www.osha.gov/pls/oshaweb/owadisp.show_document?p_ table=STANDARDS&p_id=10751

Occupational Safety & Health Administration [OSHA]. (2011). Construction focus four: fall hazards –instructor guide. OSHA Training Institute. Retrieved from https://www.osha.gov/dte/ outreach/construction/focus_four/falls/falls_ig.pdf

Occupational Safety & Health Administration [OSHA]. (2013). Commonly used statistics. U.S. Department of Labor. Retrieved from https://www.osha.gov/oshstats/commonstats.html

Occupational Safety & Health Administration [OSHA]. (2014). Regulations (Standards-29 CFR 1910.67). Retrieved from https:// www.osha.gov/pls/oshaweb/owadisp.show_document?p_id=9732&p_ table=STANDARDS

Perry, M. J., & Ronk, C.J. (2010). Preventing falls from ladders in construction: a guide to training site supervisors. Boston, MA: Harvard School of Public Health. Retrieved from http://www.elcosh.org/document/2079/d001094/ Preventing%2BFalls%2Bfrom%2BLadders%2Bin%2BConstruction %253A%2BA%2BGuide%2Bto%2B Training%2BSite%2BSupervisors.html

Ronk, C. J., Dennerlein, J.T., Hoffman, E., & Perry, M.J. (2011). Is renovation riskier than new construction? An observational comparison of risk factors for stepladder-related falls. American Journal of Industrial Medicine, 54(8), 579-585

Sparer, E. H., & Dennerlein, J.T. (2013). Determining safety inspection thresholds for employee incentives programs on construction sites. Safety Science, 51(1), 77-84

Wang, E. (1999). Mortality among North Carolina construction workers, 1988-1994. Applied Occupational and Environmental Hygiene, 14(1), 45-58

Study Safety Investigators and Advisors

Melissa J. Perry, ScD, MHS

Principal Investigator

Department of Environmental and Occupational Health

The George Washington University

Milken Institute School of Public Health

Amanda McQueen, MPH

Student Researcher

Department of Environmental and Occupational Health

The George Washington University Milken Institute School of Public Health

Seung-Sup Kim, MD, ScD

Student Researcher

Assistant Professor of Epidemiology & Global Health

School of Health

Policy and Management

Korea University

Lucy Lowenthal, MBA

Study Advisor

Project Manager, Office of the Dean

The George Washington University Milken Institute School of Public Health

Mike Whitmore

Senior Superintendent

The Whiting-Turner Contracting Company

Study Safety Expert Panel

Ted Christensen, CSP

Director of Contracting Services

Liberty Mutual Research Institute

Bruce Lippy, PhD, CIH, CSP

Director of Safety Research

CPWR

Michael McCann

Volunteer at NYCOSH

(previously at CPWR)

Jim Platner, PhD, CIH

Associate Director

Science & Technology

CPWR

David P. Powell

Director of Labor Relations

Associated General Contractors of Massachusetts

Mark Fullen, EdD, CSP

Associate Professor

West Virginia University

DESIGN of Document: Julie Farrar

EDITORS: Kellyn Betts, Sheila Cherry

PHOTO CREDITS: Seung-Sup Kim, Neil Lippy, Amanda McQueen, Shamet Qejvani

© 2015, CPWR – The Center for Construction Research and Training.

Research for this report was funded by CPWR - The Center for Construction Research and Training, using grant U60 OH009762 from the National Institute of Occupational Safety and Health (NIOSH). The contents are solely the responsibility of the authors and do not necessarily represent the official views of NIOSH, The George Washington University Milken Institute School of Public Health, or CPWR.