A Performance Goal for Construction Safety and Health

Summary Statement

CPWR researcher proposes a national goal of fewer than three deaths per 200 million man-hours of work in the US construction industry. The goal is based on international comparisons as well as contemporary accident rates reported in the United States.

1995

Contents

Projected Effect on Injuries and Deaths

Projected Economic Benefit

How to Achieve the Goal

Prospects for Achieving the Goal

Conclusion

Figures

-

1. Comparison

of lost workdays, U.S. Bureau of Labor Statistics (BLS) and National Constructors

Association (NCA), for Standard Industrial Classification 16, per 100

full-time workers, 1981-93

2. US Army Corps of Engineers, contractor lost-workday rates, 1988-94

3. Lost-time injury rate by size of firm, United States, 1993

4. Lost-time injury incidence rates in construction, 1984-93, United States

Tables

-

1.

Reported deaths in construction: rates and construction as a percentage

of total, selected countries, 1992

2. Estimates of cost reductions if proposed goal is met, in 1993 figures

3. The main safety and health hazards for the construction worker

Construction is one of the largest industries in the United States, with 5 to 6 percent of the labor force producing 13 percent of the gross national product. Construction is also one of the most dangerous industries, accounting for 15 percent of work-related deaths 1and at least 15 percent of all workers' compensation costs.2

Goals provide individuals

a clear understanding of the performance they should expect of others

-- or achieve themselves. In construction, where responsibility for decision

making is diffuse, goals are especially important. Construction owners

should know what to expect from construction contracting companies. Construction

companies should know what performance to expect throughout the chain

of command. Employees, in turn, should know what to expect from employers.

Research to date in the United States has produced enough data to enable us to begin to establish a national goal -- or benchmark -- for safety and health for the industry.

At

present, the industry should be able to achieve the following levels:

| Deaths from

injuries:<3 cases per 200 million hours worked Lost-time injuries: <1 case per 200,000 hours worked. |

Deaths. Work-related death rates from injury in construction vary greatly among nations (table 1).3 The Netherlands, with a rate of 3.3 appears to have the best record. Given the achievement in that country, it should be possible to operate a construction industry with fewer than 3 work-related deaths per 200 million hours worked.

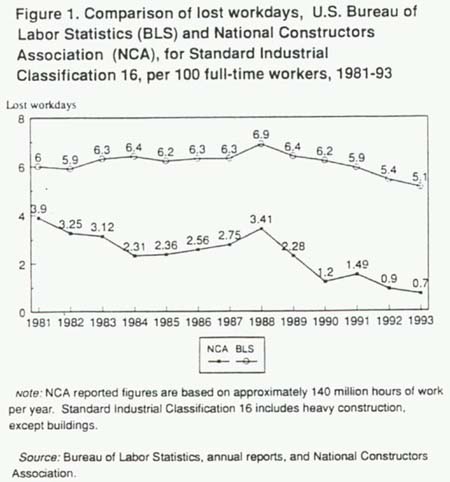

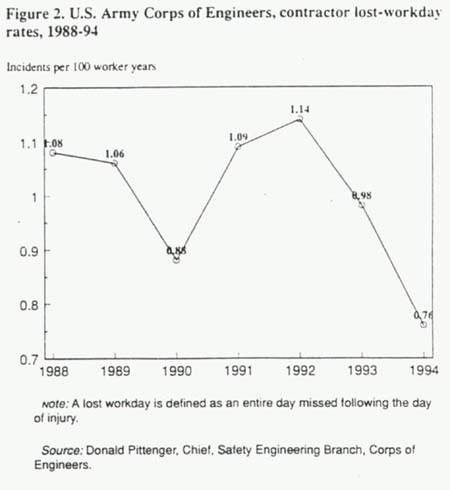

Injuries There is growing evidence to support the goal of less than 1 lost-time injury per 200,000 hours worked (which in the United States equals a rate of 1 per 100 full-time-equivalent workers). 4The National Constructors Association (NCA) comprises the largest union contractors in the United States, who support about 140 million hours of construction work annually. NCA members' reported lost-time injury rates are below 1 per 200,000 hours and are less than 20 percent of the national average reported by the US Bureau of Labor Statistics (figure 1). 5The US Army Corps of Engineers is responsible for arranging much of the heavy construction that is performed for the federal government. Although the lost-time injury rate for Army Corps projects in some years has exceeded 1, the average composite rate for 1988-94 was below 1(figure 2).6

| Outcome | Reduction | Cases saved (percent) |

| Deaths from injuries | From 950 to 160 | 790 (83) |

| Injuries | From 226,000 to 38,000 | 188,000 (83) |

Estimates for the indirect costs associated with serious injuries include job shutdowns, paper work, litigation, lost production, reduced productivity due to changes in teams, and retraining of workers. These estimates suggest that reduced indirect costs would at least double the total savings. 8

In 1993, the National Conference on Ergonomics, Safety, and Health in Construction, in Washington, D.C., reviewed the state of knowledge and identified priority areas in safety and health (table 3).

Table

3. The main safety and health hazards for the construction worker

Deaths and Injuries

- Type of injury

- Fall from elevation

- Struck by/against (falling object or machinery)

- Caught in/between (trench cave-ins, between vehicle & object)

- Electrocution

| Musculoskeletal disorders, all trades | |

| Cause of injury | Areas most affected |

| Lifting | Lower back, shoulders |

| Awkward postures | Knee, hip, shoulders |

| Repetitive motion | Wrists |

| Hand-tool vibration | Fingers, wrists |

| Chronic health hazards | |

| Hazard | Organs or systems most affected |

| Noise | Hearing |

| Asbestos & manmade fibers | Lungs |

| Lead & other metals | Kidneys, nervous & reproductive systems |

| Solvents | Kidneys, liver, nervous system |

| Hazardous wastes | Kidneys, liver, nervous & reproductive systems |

| Heat stress & extreme cold | Circulatory system |

- Source: CPWR – Center for Construction Research and Training, based on reports from the US Bureau of Labor Statistics and Bygghälsan, the Swedish Construction Industry Organization for Working Environment, Occupational, Safety and Health.

The conference identified four major interventions to affect the risk factors:

- Improved site planning and management

- Improved training of workers and supervisors

- New construction technologies

- Markedly improved performance monitoring and data.

The conference also identified the key decisionmakers who need to be mobilized if this agenda for change is to be implemented industry wide. They are employers, construction owners, union leaders, government officials, workers' compensation insurance executives, academic investigators, and architects and designers.

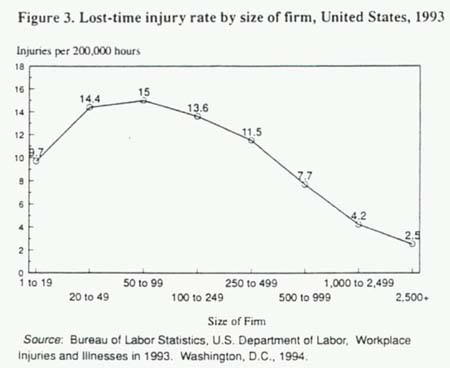

When lost-time injury rates are examined by size of firm, the larger employers have a markedly lower rate (figure 3). The largest employers in the National Constructors Association, on average, already operate at a rate that is roughly half the rate of the proposed goal. The real issue is to improve performance among small-to-medium employers.9

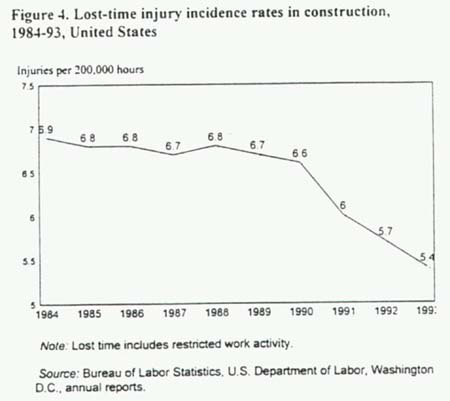

There is evidence

that this goal is realistic, that lost-time injury rates can be brought

down substantially. According to the Bureau of Labor Statistics, lost-time

injury rates in the US construction industry as a whole declined by 19

percent in the most recent three years for which

BLS has data, from

1990 to 1993 (figure 4). This is a startling decline,

which is not replicated in other industries and which cannot be explained

by unrelated factors, such as the business cycle. It seems most likely

that this decline has resulted from a series of events that have increased

safety awareness in the industry. We are seeking to verify the factors,

but they may include:

- A realization by the unions that government inspection programs were not going to have the expected effect on the industry. As a result, several unions in the mid-to-late 1980s established — with employers — large-scale safety and health programs.10

- A growing awareness and interest in construction safety and health in the states and voluntary organizations.11

- A realization by construction owners, led by the Business Roundtable, that the costs of injuries and illnesses were becoming too great, which led them to call for improved safety performance.12 This, coupled with the newly emerging total quality management movement, has been widely embraced by industry. Thus, the industry-sponsored Construction Industry Institute at the University of Texas investigated the potential for improved safety and health performance and developed a "zero-accident" philosophy that has been adopted fairly broadly.13

- A realization by construction employers that safety and health performance was becoming a competitive factor that could affect their ability to win bids.

- A changing philosophy

in the US Occupational Safety and Health Administration (OSHA), which

has manifested itself in two ways. First, OSHA has been giving greater

emphasis to performance --m as opposed to specification -- standards.

Among the most important performance standards are the Hazardous Waste

Operations and Emergency Response Standard (1989) and the Process Safety

Management of Highly Hazardous Chemicals Standard (1992). Both of these

codify what may be considered "best practices" and "continuous improvement."

Second, OSHA has increasingly emphasized cooperation, consultation activities,

and voluntary protection programs in an effort to use incentives to

promote better safety and health performance. In 1990 OSHA established

the Office of Construction and Engineering to focus its activities directed

at the industry.

This proposal does not conflict with other guidelines, such as the zero-accident philosophy. The zero-accident work environment is an ideal. Rather, this goal attempts to establish what is feasible. In this respect, the proposal does two things. First, it responds to the basic requirement in the establishment of any safety standard: it demonstrates technological and economic feasibility. Second, it departs from the traditional approach to setting safety and health standards, which is rooted in engineering, and instead uses a public health approach, which focuses on injury rates as a measure of performance.

Some caveats or refinements to this goal need to be addressed. First, there are inconsistent definitions for a lost-time or lost-workday case, depending on the research organization or jurisdiction. OSHA is trying to address this problem, in its proposals to revise record keeping requirements of employers for injuries and illnesses. Second, some sectors of the industry with highly specialized work, such as structural steel erection, may require separate goals.

In addition, chronic disease outcomes are greatly understated, even when illness rates are reported to BLS.15 Most occupational illnesses cannot be counted by employers in general, and by employers in construction in particular, because of the long time such illnesses usually take to develop and the multiple causes of most illnesses. And in construction, the temporary nature of much employment makes it difficult to track individual worker exposures to hazards -- and individual workers.

Industry wide achievement of the proposed goal would require great strides. In spite of the remarkable improvements in safety in the US construction industry, the goal is at a level one-fourth of current industry lost-time injury and work-related-death rates. Thus, any expectation of immediate achievement of the goal would be unrealistic. Still, if there is one characteristic that typifies construction, it is its ability to adapt rapidly to change.

As has been shown, large construction contractors already operate at or close to the proposed goal. The real issue is finding ways to broaden our focus and direct our attention to small-to-medium employers, which in the United States exceed 425,000 in number. 16If we can create an environment where this part of the industry moves toward broad adoption of a safety culture much like the one large employers are developing, the goal should be achievable.

We believe the labor unions serve a pivotal role in this respect, because it is the collective bargaining agreements -- and multiemployer benefit programs created under them -- that enable employers to sustain themselves in an industry where the levels of employment vary markedly. The move toward increased union-employer cooperation in safety and health in our industry probably provides the greatest potential to move the industry toward the goal proposed here.

- Bureau of Labor Statistics, US Department of Labor, National Census of Fatal Occupational Injuries, 1993, Washington, DC, 1994.

- The costs for workers' compensation in construction are difficult to estimate. John Burton, PhD, editor, Workers' Compensation Monitor, reports that these costs totaled $11.6 billion in 1994, which was 15% of total workers' compensation costs and which would equal $1.50 per hour per worker. On the other hand, a survey found that workers' compensation premium rates for carpenters, bricklayers, and iron workers averaged roughly 28% of payroll, (Engineering News-Record, Sept. 26, 1994, p. 40). If this rate were applied to all construction, it would amount to a cost of $4.20 per hour per worker. Estimates of the costs of workers' compensation in 1992 ranged from $9.8 billion to $40 billion, with the best estimate at about $18 billion, or 30% of total workers' compensation costs (see Knut Ringen, letter to Dr. Devra L. Davis, US Department of Health and Human Services, Jan 6, 1994). This would equal roughly $2.40 per hour per worker.

- Great care has been taken to make the rates in table 1 as comparable as possible. Nonetheless, there are problems in comparing rates for different nations because of definitional differences. See Earl Pollack, Standardizing Safety and Health Statistics in Construction. XIV International Conference, The International Section of the International Social Security Association for the Prevention of Occupational Risks in the Construction Industry (Madrid, 24-26 October 1994), Geneva, ISSA, 1994.

- Variations in definitions hamper comparison of lost-time injury rates. The Bureau of Labor Statistics includes any injury that results in days away from work or restricted duties. In 1993, BLS began to publish data for total lost-time injuries, which include days-away-from-work-only cases and restricted-work cases. Whether these categories are combined or separate for construction makes little difference, because employers in construction rarely report restricted cases as lost-workday cases. In addition, the distinction between injury and illness is fairly arbitrary, especially in cases involving musculoskeletal disorders such as strains and sprains. This injury-illness distinction is also not that significant for construction, because construction employers report few cases of illnesses. The Occupational Safety and Health Administration is currently attempting to clarify these issues in a proposal to revise employer record keeping requirements. In this paper, the BLS rates presented in figures 1 through 4 may use differing definitions, depending on the data that were available. As noted, however, the differences are small in terms of construction and do not alter the overall findings. For instance, a total of 227,900 lost-time injuries were reported in 1993; of these, 204,000 involved days away from work.. (Restricted-work cases are about 10 percent of the total in construction, unlike in manufacturing, where about 40 percent of cases are restricted-work cases.) Cases of days away from work involving illnesses were only 2 percent of the total. For most of the BLS data used in this paper, see Bureau of Labor Statistics, US Department of Labor, Workplace Injuries and Illnesses in 1993, Washington, DC, Dec. 21, 1994.

- Similarly, member companies in the Construction Industry Institute, most of whom are large, in 1993 reported a composite lost workday case incidence rate of between 0.6 and 0.7 (for one day or more away from work). This information was provided by Jon Vanden Bosch, director, safety and health programs, Construction Industry Institute, March 16, 1995.

- Data for 1988-94 were provided by Donald A. Pittenger, chief, Safety Engineering Branch, Safety and Occupational Health Division, Chief of Engineers, US Army Corps of Engineers, Washington, DC For earlier data, see Occupational Safety and Health Administration, US Department of Labor, Construction Lost Time Injuries: The US Army Corps of Engineers Data Base 1984-1988, Washington, DC, Office of Construction and Engineering, December 1992.

- According to BLS, in 1993, there were 7.2 million workers employed in construction. Of these, 1.5 million to 1.7 million were self-employed. Lost-time injury rates for the self-employed are probably not calculated by BLS. Similarly, these workers are not included in workers' compensation data. To err on the conservative side, we have estimated cost savings for a workforce of 5.5 million employed. workers in the US The estimate of 1,350 hours worked is a conservative estimate of average employment in construction per construction workers in 1993, based on the low level of activity in the industry that year. For instance, BLS estimated 1 million full-time-equivalent construction workers were unemployed that year, compared with 705,000 in 1990. The estimate of the hourly wage is for June 1994 and is taken from Bureau of Labor Statistics, US Department of Labor, Employment and Earnings, July 1994.

- For instance, see Jimmie Hinze, Indirect Costs of Construction Accidents, Construction Industry Institute, Source Document 67, November 1991.

- The apparently lower injury rates among the large NCA and Construction Industry Institute employers correlates with findings in other data. (Construction Industry Institute members are mainly large employers; there is some overlap between NCA and Construction Industry Institute membership.) Studies have show that self-employment and small workday size correlate with increased risk of injury in construction. See Guy Toscano and Janice Windau, The changing character of fatal work injuries, Monthly Labor Review, October 1994, pp. 17-28, and Barbara Marsh, Chance of getting hurt is generally far higher at smaller companies, Wall Street Journal, Feb. 3, 1994, A-1 (original research).

- The Building and Construction Trades Department, AFL-CIO, already in the late 1970s had established a safety and health department to promote programs among its affiliates and employers. For instance, the Laborers' International Union of North America, which represents about 700,000 members, at its 1986 convention voted to establish a major safety and health program in cooperation with employers. As a result, in 1988 it formed what is now the Laborers' Health and Safety Fund of North America as a joint union-employer trust. By the end of 1990, the program had more than 30 staff, including specialized safety and health representatives throughout the United States and Canada. Other unions, such as the United Brotherhood of Carpenters, have followed suit.

- For instance, the Chicagoland Construction Safety Council and the Illinois Construction Safety Council were created by labor and management in 1990 to highlight the need for improved performance in the industry. By February 1995, the fifth annual construction safety and health conference for these councils had more than 1,000 registrants. Also, governors' safety conferences, which are held annually in man states, now have construction as a top agenda item. In 1993, after lengthy planning, the National Safety Council established a separate Construction Division, and in 1994 the American Conference of Governmental Industrial Hygienists created a separate column on construction safety and health in its journal, Applied Occupational and Environmental Hygiene.

- See Business Roundtable, Improving Construction Safety Performance: A Construction Industry Cost-Effectiveness Project Report. New York, 1982, Report A-3.

- See Construction Industry Institute, Zero Injury Techniques, Austin, Texas, 1993, publ. 31-1.

- For an example of a very useful and practical overview of total quality management principles as applied to construction, see Construction Industry Development Agency, Building Best Practices in the Construction Industry: A Practitioner's Guide, Sydney, Australia, October 1993. See also O. Sjoholt, ed., Qualit Management in Building and Construction, Oslo (Norwegian Building Research Institute), 1994.

- One study, in New York State, found that only three cases of occupation-related cancer, out of an estimated 3,700 such cases, were covered by workers' compensation (Philip J. Landrigan and Steven Markowitz, Occupational Disease in New York State, Mount Sinai School of Medicine, Department of Communit Medicine, 1987).

- The commission chaired by John T. Dunlop estimated that, in June 1992, 425,000 construction firms had less than 10 employees. See Commission on the Future of Worker-Management Relations, Fact Finding Report, May 1994, p. 95.