Summary Statement

Student manual on electrical safety with information on recognizing, evaluating and avoiding hazards related to electricity.

January 2002

Safety Model Stage 3—Controlling Hazards: Safe Work Practices

How Do You Work Safely?A safe work environment is not enough to control all electrical hazards. You must also work safely. Safe work practices help you control your risk of injury or death from workplace hazards. If you are working on electrical circuits or with electrical tools and equipment, you need to use safe work practices.

Before you begin a task, ask yourself:

- What could go

wrong?

- Do I have the knowledge, tools, and experience to do this work safely?

Control electrical hazards through safe work practices.

- Plan your work

and plan for safety.

- Avoid wet working

conditions and other dangers.

- Avoid overhead

powerlines.

- Use proper wiring

and connectors.

- Use and maintain

tools properly.

- Wear correct PPE.

Take time to plan your work, by yourself and with others. Safety planning is an important part of any task. It takes effort to recognize, evaluate, and control hazards. If you are thinking about your work tasks or about what others think of you, it is hard to take the time to plan for safety. But, YOU MUST PLAN.

| Plan to be safe. |

| Don't work alone. |

| A 40-year-old

male meter technician had just completed a 7-week basic lineman training

course. He worked as a meter technician during normal working hours

and as a lineman during unplanned out-ages. One evening, he was called

to repair a residential power outage. By the time he arrived at the

site of the outage, he had already worked 2 hours of overtime and

worked 14 straight hours the day before. At the site, a tree limb

had fallen across an overhead powerline. The neutral wire in the line

was severed, and the two energized 120-volt wires were disconnected.

The worker removed the tree limb and climbed up a power pole to reconnect

the three wires. He was wearing insulated gloves, a hard hat, and

safety glasses. He prepared the wires to be connected. While handling the wires, one of the energized wires caught the cuff of his left glove and pulled the cuff down. The conductor contacted the victim’s forearm near the wrist. He was electrocuted and fell backwards. He was wearing a climbing belt, which left him hanging upside down from the pole. Paramedics arrived 5 minutes after the contact. The power company lowered his dead body 30 minutes later. Several factors may have contributed to this incident. Below are some ways to eliminate these risk factors.

|

|

| Test circuits to make sure they are de-energized. |

Planning with others is especially helpful. It allows you to coordinate your work and take advantage of what others know about identifying and controlling hazards. The following is a list of some things to think about as you plan.

- Work with a “buddy”—Do not work alone. Both of you should be trained in CPR. Both of you must know what to do in an emergency.

- Know how to

shut off and de-energize circuits—You must find where circuit

breakers, fuses, and switches are located. Then, the circuits that you

will be working on (even low-voltage circuits) MUST BE TURNED OFF!

Test the circuits before beginning work to make sure they are completely

de-energized.

This worker is applying a group lock-out device. The equipment cannot be re-started until all workers remove their locks.

- Plan to lock

out and tag out circuits and equipment—Make certain all energy

sources are locked out and tagged out before performing any work on

an electrical circuit or electrical device. Working on energized (“hot”)

circuits is one of the most dangerous things any worker could do. If

someone turns on a circuit without warning, you can be shocked, burned,

or electrocuted. The unexpected starting of electrical equipment can

cause severe injury or death.

Before ANY work is done on a circuit, shut off the circuit, lock out and tag out the circuit at the distribution panel, then test the circuit to make sure it is de-energized.

Before ANY equipment inspections or repairs—even on so-called low-voltage circuits—the current must be turned off at the switch box, and the switch must be padlocked in the OFF position. At the same time, the equipment must be securely tagged to warn everyone that work is being performed. Again, test circuits and equipment to ensure they are de-energized.

No two locks should be alike. Each key should fit only one lock, and only one key should be issued to each worker. If more than one worker is working on a circuit or repairing a piece of equipment, each worker should lock out the switch with his or her own lock and never permit anyone else to remove it. At all times, you must be certain that you are not exposing other workers to danger. Workers who perform lock-out/tag-out must be trained and authorized to repair and maintain electrical equipment. A locked-out switch or feeder panel prevents others from turning on a circuit. The tag informs other workers of your action.

- Remove jewelry and metal objects—Remove jewelry and other metal objects or apparel from your body before beginning work. These things can cause burns if worn near high currents and can get caught as you work.

- Plan to avoid falls—Injuries can result from falling off scaffolding or ladders. Other workers may also be injured from equipment and debris falling from scaffolding and ladders.

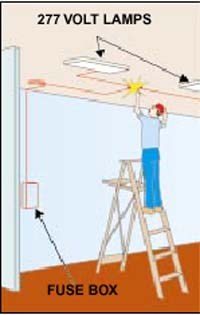

A

worker was attempting to correct an electrical problem involving two

non-operational lamps. He examined the circuit in the area where he

thought the problem was located. He had not shut off the power at

the circuit breaker panel and did not test the wires to see if they

were live. He was electrocuted when he grabbed the two live wires

with his left hand. He collapsed to the floor and was found dead. A

worker was attempting to correct an electrical problem involving two

non-operational lamps. He examined the circuit in the area where he

thought the problem was located. He had not shut off the power at

the circuit breaker panel and did not test the wires to see if they

were live. He was electrocuted when he grabbed the two live wires

with his left hand. He collapsed to the floor and was found dead.

|

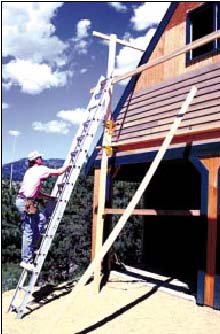

Ladder Safety Fact Sheet

To prevent injury

when climbing, follow these procedures:

To prevent injury

when climbing, follow these procedures:1. Position the ladder at a safe angle to prevent slipping. The horizontal distance from the base of the ladder to the structure should be one-quarter the length of the ladder. If you don’t have a way

to make this measurement, follow the steps below to determine if the ladder is positioned at a safe angle.

- Put your feet

at the base of the ladder and extend your arms straight out.

- If you can touch

the closest part of the ladder without bending your arms, the ladder

is probably at the correct angle.

- If you have to bend your arms to touch the closest part of the ladder or if you can’t reach the ladder at all, the ladder is not positioned at a safe angle.

3. Follow the manufacturer’s recommendations for proper use.

4. Check the condition of the ladder before using it. Joints must be tight to prevent wobbling or leaning.

|

|

|

|

6. When using scaffolding, use a ladder to access the tiers. Never climb the cross braces.

7. Do not use metal ladders. Instead, use ladders made of fiberglass. (Although wooden ladders are permitted, wood can soak up water and become conductive.)

8. Beware of overhead powerlines when you work with ladders and scaffolding.

| Learn how to use ladders and scaffolding properly. |

| A crew of 7

workers was painting a 33-foot sign at a shopping mall. The crew used

tubular welded frame scaffolding that was 31 feet tall and made up

of several tiers. The sign was partially painted when the crew was

instructed to move the scaffolding so that concrete could be poured

for an access road. The crew moved the scaffolding 30 feet without

disassembling it. An overhead powerline was located about 10 feet

away from the scaffolding. After the concrete hardened, the workers

lifted the scaffolding to move it back to the sign. The top tier came

loose, fell, and contacted the powerline. All seven workers were knocked

away from the scaffolding. Two died; five were hospitalized. You must take certain precautions when working with scaffolding.

|

|

|

| A company was

contracted to install wiring and fixtures in a new office complex.

The third floor was being prepared in a hurry for a new tenant, and

daily changes to the electrical system blueprints were arriving by

fax. The light fixtures in the office were mounted in a metal grid

that was fastened to the ceiling and properly grounded. A 23-year-old male apprentice electrician was working on a light fixture when he contacted an energized conductor. He came down from the fiberglass ladder and collapsed. Apparently, he had contacted the “hot” conductor while also in contact with the metal grid. Current passed through his body and into the ground-ed grid. Current always takes a path to ground. In this case, the worker was part of that path. He was dead on arrival at a nearby hospital. Later, an investigation showed that the victim had cross-wired the conductors in the fixture by mistake. This incorrect wiring allowed electricity to flow from a live circuit on the completed section of the building to the circuit on which the victim was working. Below are some safety procedures that should have been followed in this case. Because they were ignored, the job ended in death.

|

Avoid wet working conditions and other dangers

Remember that any hazard becomes much more dangerous in damp or wet conditions. To be on the safe side, assume there is dampness in any work location, even if you do not see water. Even sweat can create a damp condition!

-

Do not work wet—Do not work on circuits or use electrical equipment in damp or wet areas. If necessary, clear the area of loose material or hanging objects. Cover wet floors with wooden planking that can be kept dry. Wear insulating rubber boots or shoes. Your hands must be dry when plugging and unplugging power cords and extension cords. Do not get cleaning solutions on energized equipment.Avoid wet conditions! Even avoid damp conditions!

Portable GFCI. - Use a GFCI—Always use a GFCI when using portable tools and extension cords.

Be very careful not to contact overhead powerlines or other exposed wires. More than half of all electrocutions are caused by contact with overhead lines. When working in an elevated position near overhead lines, avoid locations where you (and any conductive object you hold) could contact an unguarded or uninsulated line. You should be at least 10 feet away from high-voltage transmission lines.

Vehicle operators should also pay attention to overhead wiring. Dump trucks, front-end loaders, and cranes can lift and make contact with overhead lines. If you contact equipment that is touching live wires, you will be shocked and may be killed. If you are in the vehicle, stay inside. Always be aware of what is going on around you.

| A

worker from an electrical service company was changing bulbs in pole-mounted

light fixtures in a shopping center parking lot. The procedure for

installing the bulbs was as follows: The worker would park the truck

near the first light pole. The truck was equipped with a roof-mounted

ladder. The worker would extend the ladder high enough to change the

bulb, then drive to the next pole without lowering the ladder. After the worker replaced the first bulb, he got back in the truck and drove toward the next light pole. As the truck moved along, a steel cable attached to the top of the ladder contacted an overhead powerline. The worker realized something was wrong, stopped the truck, and stepped onto the pavement while still holding onto the door of the truck. By doing this, he completed the path to ground for the current in the truck. Because the ladder was still in contact with the powerline, the entire truck was now energized. He was engulfed in flames as the truck caught fire. Fire, police, and paramedic units arrived within 5 minutes. Utility workers arrived in about 10 minutes and de-energized (shut off) the powerline. The victim burned to death at the scene. Below are some ways to prevent contact with overhead powerlines.

|

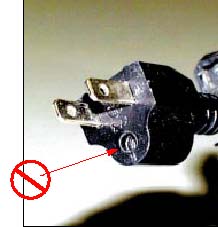

Use proper wiring and connectors

- Avoid overloads—Do not overload circuits.

- Test GFCI’s—Test GFCI’s monthly using the “test” button.

- Check switches

and insulation—Tools and other equipment must operate properly.

Make sure that switches and insulating parts are in good condition.

Never use a three-prong grounding plug with the third prong broken off.

- Use three-prong plugs—Never use a three-prong grounding plug with the third prong broken-off. When using tools that require a third-wire ground, use only three-wire extension cords with three-prong grounding plugs and three-hole electrical outlets. Never remove the grounding prong from a plug! You could be shocked or expose someone else to a hazard. If you see a cord without a grounding prong in the plug, remove the cord from service immediately.

- Use extension cords properly—If an extension cord must be used, choose one with sufficient ampacity for the tool being used. An undersized cord can overheat and cause a drop in voltage and tool power. Check the tool manufacturer’s recommendations for the required wire gauge and cord length. Make sure the insulation is intact. To reduce the risk of damage to a cord’s insulation, use cords with insulation marked “S” (hard service) rather than cords marked “SJ” (junior hard service). Make sure the grounding prong is intact. In damp locations, make sure wires and connectors are waterproof and approved for such locations. Do not create a tripping hazard.

- Check power

cords and extensions—Electrical cords should be inspected regularly

using the following procedure:

-

1. Remove the

cord from the electrical power source before inspecting.

2. Make sure the grounding prong is present in the plug.

3. Make sure the plug and receptacle are not damaged.

4. Wipe the cord clean with a diluted detergent and examine for cuts, breaks, abrasions, and defects in the insulation.

5. Coil or hang the cord for storage. Do not use any other methods. Coiling or hanging is the best way to avoid tight kinks, cuts, and scrapes that can damage insulation or conductors.

using a continuity tester as follows:

-

1. Connect one

lead of the tester to the ground prong at one end of the cord.

2. Connect the second lead to the ground wire hole at the other end of the cord.

3. If the tester lights up or beeps (depending on design), the cord’s ground wire is okay. If not, the cord is damaged and should not be used.

- Do not pull on cords—Always disconnect a cord by the plug.

- Use correct

connectors—Use electrical plugs and receptacles that are right

for your current and voltage needs. Connectors are designed for specific

currents and voltages so that only matching plugs and receptacles will

fit together. This safeguard prevents a piece of equipment, a cord,

and a power source with different voltage and current requirements from

being plugged together. Standard configurations for plugs and receptacles

have been

established by the National Electric Manufacturers Association (NEMA).

Locking-type attachment plug. - Use locking connectors—Use locking-type attachment plugs, receptacles, and other connectors to prevent them from becoming unplugged.

Use and maintain tools properly

Your tools are at the heart of your craft. Tools help you do your job with a high degree of quality. Tools can do something else, too. They can cause injury or even death! You must use the right tools for the job. Proper maintenance of tools and other equipment is very important. Inadequate maintenance can cause equipment to deterio-rate, creating dangerous conditions. You must take care of your tools so they can help you and not hurt you.

|

|

|

|

|

| This cord has been spliced using a wire nut. Spliced cords are very dangerous! |

- Inspect tools before using them—Check for cracked casings, dents, missing or broken parts, and contamination (oil, moisture, dirt, corrosion). Damaged tools must be removed from service and properly tagged. These tools should not be used until they are repaired and tested.

- Use the right tool correctly—Use tools correctly and for their intended purposes. Follow the safety instructions and operating procedures recommended by the manufacturer. When working on a circuit, use approved tools with insulated handles. However, DO NOT USE THESE TOOLS TO WORK ON ENERGIZED CIRCUITS. ALWAYS SHUT OFF AND DE-ENERGIZE CIRCUITS BEFORE BEGINNING WORK ON THEM.

- Protect your tools—Keep tools and cords away from heat, oil, and sharp objects. These hazards can damage insulation. If a tool or cord heats up, stop using it! Report the condition to a supervisor or instructor immediately. If equipment has been repaired, make sure that it has been tested and certified as safe before using it. Never carry a tool by the cord. Disconnect cords by pulling the plug—not the cord!

- Use double-insulated

tools—Portable electrical tools are classified by the number

of insulation barriers between the electricalconductors in the tool

and the worker. The NEC permits the use

of portable tools only if they have been approved by Underwriter’s Laboratories (UL Listed). Equipment that has two insulation barriers and no exposed metal parts is called double-insulated.

When used properly, double-insulated tools provide reliable shock protection without the need for a third ground wire. Power tools with metal housings or only one layer of effective

insulation must have a third ground wire and three-prong plug. - Use multiple safe practices—Remember: A circuit may not be wired correctly. Wires may contact other “hot” circuits. Someone else may do something to place you in danger. Take all possible precautions.

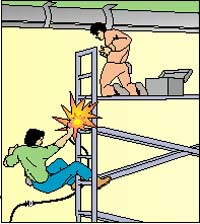

An

employee was climbing a metal ladder to hand an electric drill to

the journeyman installer ona scaffold about 5 feet above him. When

the victim reached the third rung of the ladder, he received an electrical

shock that killed him. An investigation showed that the grounding

prong was missing from the extension cord attached to the drill. Also,

the cord’s green grounding wire was, at times, contacting the

energized black wire. Because of this contact with the "hot"

wire, the entire length of the grounding wire and the drill’s

frame became energized. The drill was not double-insulated. An

employee was climbing a metal ladder to hand an electric drill to

the journeyman installer ona scaffold about 5 feet above him. When

the victim reached the third rung of the ladder, he received an electrical

shock that killed him. An investigation showed that the grounding

prong was missing from the extension cord attached to the drill. Also,

the cord’s green grounding wire was, at times, contacting the

energized black wire. Because of this contact with the "hot"

wire, the entire length of the grounding wire and the drill’s

frame became energized. The drill was not double-insulated.To avoid deadly incidents like this one, take these precautions:

|

|

|

|

|

|

| Don’t work on energized circuits like this one! Always follow correct lock-out/tag-out procedures. |

| A 22-year-old

male carpenter was building the wooden framework of a laundry building.

He was using portable power tools. Electricity was supplied to the

tools by a temporary service pole 50 feet away. The service pole had

not been inspected and was not in compliance. It was also not grounded.

The carpenter plugged a “homemade” cord into the service

pole and then plugged a UL-approved cord into the homemade cord. His

power saw was plugged into the UL-approved cord. The site was wet. Humidity was high and the carpenter was sweating. Reportedly, he was mildly shocked throughout the morning and replaced the extension cord he was using in an effort to stop the shocks. At one point, as he was climbing down a makeshift ladder constructed from a floor truss, he shifted the power saw from his right hand to his left hand and was shocked. He fell from the ladder into a puddle of water, still hold-ing the saw. The current had caused his hand to contract, and he was “locked” to the saw. A co-worker disconnected the power cord to the saw. CPR was given, but the shock was fatal. Attention to these general safety principles could have prevented this death.

|

Wear correct PPE

OSHA requires that you be provided with personal protective equipment. This equipment must meet OSHA requirements and be appro-priate for the parts of the body that need protection and the work performed. There are many types of PPE: rubber gloves, insulating shoes and boots, face shields, safety glasses, hard hats, etc. Even if laws did not exist requiring the use of PPE, there would still be every reason to use this equipment. PPE helps keep you safe. It is the last line of defense between you and the hazard.

| Wear and maintain PPE. |

|

- Wear safety

glasses—Wear safety glasses to avoid eye injury.

Wear safety glasses to avoid eye injury.

- Wear proper

clothing—Wear clothing that is neither floppy nor too tight.

Loose clothing will

catch on corners and rough sur-faces. Clothing that binds is uncomfortable and distracting.

Don't wear hard hats backwards! - Contain and secure loose hair—Wear your hair in such a way that it does not interfere with your work or safety.

- Wear proper foot protection—Wear shoes or boots that have been approved for electrical work. (Tennis shoes will not protect you from electrical hazards.) If there are non-electrical hazards present (nails on the floor, heavy objects, etc.), use footwear that is approved to protect against these hazards as well.

- Wear a hard hat—Wear a hard hat to protect your head from bumps and falling objects. Hard hats must be worn with the bill forward to protect you properly.

- Wear hearing protectors—Wear hearing protectors in noisy areas to prevent hearing loss.

- Follow directions—Follow the manufacturer’s directions for cleaning and maintaining PPE.

- Make an effort—Search

out and use any and all equipment that will protect you from shocks

and other injuries.

|

| Arcing electrical burns through the victim’s shoe and around the rubber sole. |

|

|

|

|

PPE Fact Sheet—The Right Equipment—Head to Toe

| PPE is the last line of defense against workplace hazards. OSHA defines PPE as "equipment for the eyes, face, head, and extremities, protective clothing, respiratory devices, protective shields and barriers." Many OSHA regulations state that PPE must meet criteria set by the American National Standards Institute (ANSI). |

|

|

Head

Protection

|

OSHA requires that head protection (hard hats) be worn if there is a risk of head injury from electrical burns or falling/flying objects.

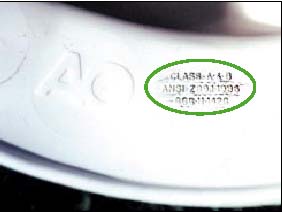

Aren’t all hard hats the same?

No. You must wear the right hat for the job. All hard hats approved for electrical work made since 1997 are marked "Class E." Hard hats made before 1997 are marked "Class B." These markings will be on a label inside the helmet or stamped into the helmet

itself. Newer hats may also be marked "Type 1" or "Type 2." Type 1 hard hats protect you from impacts on the top of your head. Type 2 hard hats protect you from impacts on the top and sides of your head.

|

|

| Class E, Type 1 hard hat. | Class B hard hat. |

|

| Don’t wear another hat under your hard hat! |

Always wear your hat with the bill forward. (Hats are tested in this position.) If you wear a hat differently, you may not be fully protected. The hat should fit snugly without being too tight. You should clean and inspect your hard hat regularly according to the manufacturer’s

instructions. Check the hat for cracks, dents, frayed straps, and dulling of the finish. These conditions can reduce protection. Use only mild soap and water for cleaning. Heavy-duty cleaners and other chemicals can damage the hat.

Do not "store" anything (gloves, wallet, etc.) in the top of your hard hat while you are wearing it. The space between the inside harness and the top of the hard hat must remain open to protect you. Do not put stickers on your hat (the glue can weaken the helmet) and keep it out of direct sunlight. If you want to express your personality, hard hats come in many colors and can be imprinted with custom designs by the manufacturer. Some hats are available in a cowboy hat design or with sports logos.

|

|

| Never

“store” anything in the top of your hard hat while you are wearing it. |

Class

B hard hat in a cowboy hat design. |

|

| Keep your hard hat out of direct sunlight when you are not wearing it! |

|

Use

your head and protect your head!

|

|

| Foot Protection |

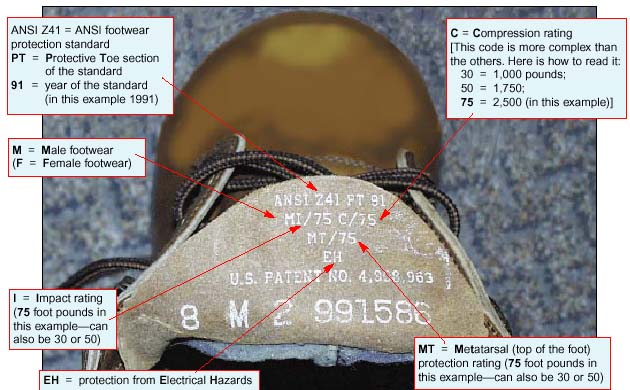

Workers must wear protective footwear when there is a risk of foot injury from sharp items or falling/rolling objects—or when electrical hazards are present. As with hard hats, always follow the manufacturer’s instructions for cleaning and maintenance of footwear. Remember that cuts, holes, worn soles, and other damage can reduce protection.

How do I choose the right footwear?

The footwear must be ANSI approved. ANSI approval codes are usually printed inside the tongue of the boot or shoe. Footwear will be marked "EH" if it is approved for electrical work. (The ANSI approval stamp alone does not necessarily mean the footwear offers protection from electrical hazards.) Note that footwear made of leather must be kept dry to protect you from electrical hazards, even if it is marked "EH."

What about non-electrical hazards?

All ANSI approved footwear has a protective toe and offers impact and compression protection. But the type and amount of protection is not always the same. Different footwear protects you in different ways. Check the product’s labeling or consult the manufacturer to make sure the footwear will protect you from the hazards you face.

|

Don’t

take risks because you are wearing PPE. PPE is the last line of

defense against injury!

|

Summary of Section 8

Control hazards through safe work practices.

- Plan your work

and plan for safety.

- Avoid wet working

conditions and other dangers.

- Avoid overhead

powerlines.

- Use proper wiring

and connectors.

- Use and maintain

tools properly.

- Wear correct PPE.