Summary Statement

Describes methods to inspect and test insulating gloves.

How to Perform a Field Test for Insulating Gloves

The Occupational Safety and Health Administration 29CFR 1910.137 paragraph (b)(2)(ii) requires insulating equipment to be visually inspected before use each day and immediately after any incident which might be suspected of causing damage.The ASTM Standard Specification for Rubber Insulating Gloves states that "Gloves shall be free on both inner and outer surface of harmful irregularities that can be detected through testing and inspection." Harmful irregularities are defined as any feature that disrupts the uniform, smooth surface contour and represents a potential hazard to the user, such as pinholes, cracks, blisters, cuts, conductive embedded foreign matter, creases, pinch marks, voids (entrapped air), prominent ripples, and mold marks. In addition, the OSHA Standard 29CFR1910.137 states that rubber gloves must be subjected to an air test along with the inspection.

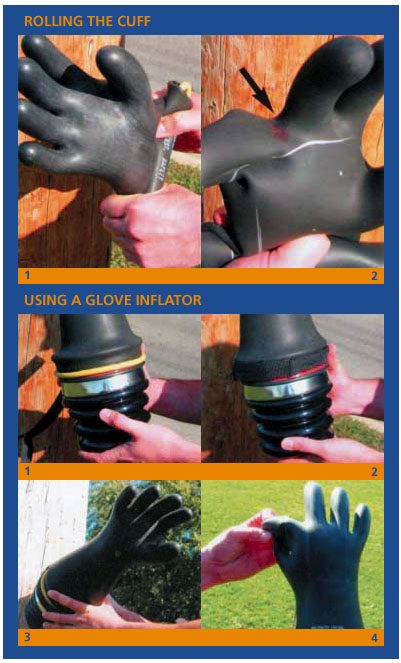

In the field, the test can be done by either rolling the cuff towards the palm so that air is entrapped within the glove or with the use of a mechanical inflator. The following information outlines a procedure on how to perform a field air test and inspection by either rolling the cuff or using a glove inflator.

Rolling the cuff:

- Grab the glove by the cuff, flip it around several times

to make a seal, and then roll the glove toward the fingers. An air

pocket will form within the glove.

- Hold tightly the rolled portion of the glove and inspect the inflated exterior of the glove for cracking or any degradation of the insulating material surface. Forcing air into the glove will expose any damage to the insulating material that might otherwise not be seen when performing only a visual inspection. In addition, you will also want to carefully inspect the glove for any holes in the insulating material. To inspect for a hole in the glove, hold the glove close to your ear. If you hear air escaping from the glove or if the glove will not hold pressure, the glove is damaged and shall be removed from service.

- Place the glove around the top of the inflator. The glove

is in place when the bead of the glove is seated in the groove of

the inflator.

- Roll the o-ring up and over the bead of the glove.

- Inflate the glove by pumping the bellows of the glove inflator

against a hard surface.

- Inspect the glove for air leaks and cracking or degradation of the insulating material.

Any glove that shows signs of surface degradation, or has a hole in the insulation, shall be immediately removed from service and either discarded or returned to a testing facility to be tested in accordance with the ASTM Standards D120-87 as specified by OSHA.

While the roll up method is still a widely accepted common practice, the use of a glove inflator inflates the entire glove thus permitting a much better inspection of the entire surface area of the glove.