Encyclopedia of Occupational Safety & Health : Chapter 93 - Construction

Summary Statement

A comprehensive overview of health and safety in construction worldwide, including trades, typical hazards, methods of prevention, regulations, management structure, and major sectors.

1998

| eLCOSH Editor's note: This is a large document. You may find it helpful using your browser's "Find in Page" feature (Control/F, or Edit/Find on Page). For example, to locate information on cement, press Control/F and enter "cement" as the search text, then click on the "Find Next" button to locate the next occurrence of "cement." |

Construction workers

build, repair, maintain, renovate, modify and demolish houses, office

buildings, temples, factories, hospitals, roads, bridges, tunnels, stadiums,

docks, airports and more. The International Labor Organization (ILO) classifies

the construction industry as government and private-sector firms erecting

buildings for habitation or for commercial purposes and public works such

as roads, bridges, tunnels, dams or airports. In the United States and

some other countries, construction workers also clean hazardous waste

sites.

Construction as a proportion of gross domestic product varies widely in

industrialized countries. It is about 4% of GDP in the United States,

6.5% in Germany and 17% in Japan. In most countries, employers have relatively

few full-time employees. Many companies specialize in skilled trades—electricity,

plumbing or tile setting, for instance—and work as subcontractors.

The Construction Labor Force

A large portion of construction workers are unskilled laborers; others

are classified in any of several skilled trades (see table

93.1). Construction workers include about 5 to 10% of the workforce

in industrialized countries. Throughout the world, over 90% of construction

workers are male. In some developing countries, the proportion of women

is higher and they tend to be concentrated in unskilled occupations. In

some countries, the work is left to migrant workers, and in others, the

industry provides relatively well-paid employment and an avenue to financial

security. For many, unskilled construction work is the entry into the

paid labor force in construction or other industries.

Work Organization

and Labor Instability

Construction projects, especially large ones, are complex and dynamic.

Several employers may work on one site simultaneously, with the mix of

contractors changing with the phases of the project; for example, the

general contractor is present at all times, excavating contractors early,

then carpenters, electricians and plumbers, followed by floor finishers,

painters and landscapers. And as the work develops—for instance,

as a building’s walls are erected, as the weather changes or as a

tunnel advances—the ambient conditions such as ventilation and temperature

change too.

Construction workers typically are hired from project to project and may

spend only a few weeks or months at any one project. There are consequences

for both workers and work projects. Workers must make and remake productive

and safe working relationships with other workers whom they may not know,

and this may affect safety at the work site. And in the course of the

year, construction workers may have several employers and less than full

employment. They might work an average of only 1,500 hours in a year while

workers in manufacturing, for example, are more likely to work regular

40 hour weeks and 2,000 hours per year. In order to make up for slack

time, many construction workers have other jobs—and exposure to other

health or safety hazards—outside of construction.

For a particular project, there is frequent change in the number of workers

and the composition of the labor force at any one site. This change results

both from the need for different skilled trades at different phases of

a work project and from the high turnover of construction workers, particularly

unskilled workers. At any one time, a project may include a large proportion

of inexperienced, temporary and transient workers who may not be fluent

in the common language. Although construction work often must be done

in teams, it is difficult to develop effective, safe teamwork under such

conditions.

Like the workforce, the universe of construction contractors is marked

by high turnover and consists mainly of small operations. Of the 1.9 million

construction contractors in the United States identified by the 1990 Census,

only 28% had any full-time employees. Just 136,000 (7%) had 10 or more

employees. The degree of contractor participation in trade organizations

varies by country. In the United States, only about 10 to 15% of contractors

participate; in some European countries, this proportion is higher but

still involves less than half of contractors. This makes it difficult

to identify contractors and inform them of their rights and responsibilities

under pertinent health and safety or any other legislation or regulations.

As in some other industries, an increasing proportion of contractors in

the United States and Europe consists of individual workers hired as independent

contractors by prime- or sub-contractors who employ workers. Ordinarily,

an employing contractor does not provide subcontractors with health benefits,

workers’ compensation coverage, unemployment insurance, pension benefits

or other benefits. Nor do prime contractors have any obligation to subcontractors

under health and safety regulations; these regulations govern rights and

responsibilities as they apply to their own employees. This arrangement

gives some independence to individuals who contract for their services,

but at the cost of removing a wide range of benefits. It also relieves

employing contractors of the obligation to provide mandated benefits to

individuals who are contractors. This private arrangement subverts public

policy and has been successfully challenged in court, yet it persists

and may become more of a problem for the health and safety of workers

on the job, regardless of their employment relationship. The US Bureau

of Labor Statistics (BLS) estimates that 9% of the US workforce is self-employed,

but in construction as many as 25% of workers are self-employed independent

contractors.

Health Hazards on Construction Sites

Construction workers are exposed to a wide variety of health hazards on the job. Exposure differs from trade to trade, from job to job, by the day, even by the hour. Exposure to any one hazard is typically intermittent and of short duration, but is likely to reoccur. A worker may not only encounter the primary hazards of his or her own job, but may also be exposed as a bystander to hazards produced by those who work nearby or upwind. This pattern of exposure is a consequence of having many employers with jobs of relatively short duration and working alongside workers in other trades that generate other hazards. The severity of each hazard depends on the concentration and duration of exposure for that particular job. Bystander exposures can be approximated if one knows the trade of workers nearby. Hazards present for workers in particular trades are listed in table 93.2 .

Table

93.2 Primary hazards encountered in skilled construction trades

Each trade is listed below with an indication of the primary hazards to

which a worker in that trade might be exposed. Exposure may occur to either

supervisors or to wage earners. Hazards that are common to nearly all

construction—heat, risk factors for musculoskeletal disorders and stress—are

not listed.

The classifications

of construction trades used here are those used in the United States.

It includes the construction trades as classified in the Standard Occupational

Classification system developed by the US Department of Commerce. This

system classifies the trades by the principal skills inherent in the trade.

| Occupations | Hazards |

| Brickmasons | Cement dermatitis, awkward postures, heavy loads |

| Stonemasons | Cement dermatitis, awkward postures, heavy loads |

| Hard tile setters | Vapor from bonding agents, dermatitis, awkward postures |

| Carpenters | Wood dust, heavy loads, repetitive motion |

| Drywall installers | Plaster dust, walking on stilts, heavy loads, awkward postures |

| Electricians | Heavy metals in solder fumes, awkward posture, heavy loads, asbestos dust |

| Electrical power installers and repairers | Heavy metals in solder fumes, heavy loads, asbestos dust |

| Painters | Solvent vapors, toxic metals in pigments, paint additives |

| Paperhangers | Vapor from glue, awkward postures |

| Plasterers | Dermatitis, awkward postures |

| Plumbers | Lead fumes and particles, welding fumes |

| Pipefitters | Lead fumes and particles, welding fumes, asbestos dust |

| Steamfitters | Welding fumes, asbestos dust |

| Carpet layers | Knee trauma, awkward postures, glue and glue vapor |

| Soft tile installers | Bonding agents |

| Concrete and terrazzo finishers | Awkward postures |

| Glaziers | Awkward postures |

| Insulation workers | Asbestos, synthetic fibers, awkward postures |

| Paving, surfacing and tamping equipment operators | Asphalt emissions, gasoline and diesel engine exhaust, heat |

| Rail- and track-laying equipment operators | Silica dust, heat |

| Roofers | Roofing tar, heat, working at heights |

| Sheetmetal duct installers | Awkward postures, heavy loads, noise |

| Structural metal installers | Awkward postures, heavy loads, working at heights |

| Welders | Welding emissions |

| Solderers | Metal fumes, lead, cadmium |

| Drillers, earth, rock | Silica dust, whole-body vibration, noise |

| Air hammer operators | Noise, whole-body vibration, silica dust |

| Pile driving operators | Noise, whole-body vibration |

| Hoist and winch operators | Noise, lubricating oil |

| Crane and tower operators | Stress, isolation |

| Excavating and loading machine operators | Silica dust, histoplasmosis, whole-body vibration, heat stress, noise |

| Grader, dozer and scraper operators | Silica dust, whole-body vibration, heat noise |

| Highway and street construction workers | Asphalt emissions, heat, diesel engine exhaust |

| Truck and tractor equipment operators | Whole-body vibration, diesel engine exhaust |

| Demolition workers | Asbestos, lead, dust, noise |

| Hazardous waste workers | Heat, stress |

Construction Hazards

As in other jobs, hazards for construction workers are typically of four

classes: chemical, physical, biological and social.

Chemical hazards

Chemical hazards are often airborne and can appear as dusts, fumes, mists,

vapors or gases; thus, exposure usually occurs by inhalation, although

some airborne hazards may settle on and be absorbed through the intact

skin (e.g., pesticides and some organic solvents). Chemical hazards also

occur in liquid or semi-liquid state (e.g., glues or adhesives, tar) or

as powders (e.g., dry cement). Skin contact with chemicals in this state

can occur in addition to possible inhalation of the vapor resulting in

systemic poisoning or contact dermatitis. Chemicals might also be ingested

with food or water, or might be inhaled by smoking.

Several illnesses have been linked to the construction trades, among them:

- silicosis among

sand blasters, tunnel builders and rock drill operators

- asbestosis (and

other diseases caused by asbestos) among asbestos insulation workers,

steam pipe fitters, building demolition workers and others

- bronchitis among

welders

- skin allergies

among masons and others who work with cement

- neurologic disorders among painters and others exposed to organic solvents and lead.

Elevated death rates

from cancer of the lung and respiratory tree have been found among asbestos

insulation workers, roofers, welders and some woodworkers. Lead poisoning

occurs among bridge rehabilitation workers and painters, and heat stress

(from wearing full-body protective suits) among hazardous-waste cleanup

workers and roofers. White finger (Raynaud’s syndrome) appears among

some jackhammer operators and other workers who use vibrating drills (e.g.,

stopper drills among tunnellers).

Alcoholism and other alcohol-related disease is more frequent than expected

among construction workers. Specific occupational causes have not been

identified, but it is possible that it is related to stress resulting

from lack of control over employment prospects, heavy work demands or

social isolation due to unstable working relationships.

Physical hazards

Physical hazards

are present in every construction project. These hazards include noise,

heat and cold, radiation, vibration and barometric pressure. Construction

work often must be done in extreme heat or cold, in windy, rainy, snowy,

or foggy weather or at night. Ionizing and non-ionizing radiation is encountered,

as are extremes of barometric pressure.

The machines that have transformed construction into an increasingly mechanized

activity have also made it increasingly noisy. The sources of noise are

engines of all kinds (e.g., on vehicles, air compressors and cranes),

winches, rivet guns, nail guns, paint guns, pneumatic hammers, power saws,

sanders, routers, planers, explosives and many more. Noise is present

on demolition projects by the very activity of demolition. It affects

not only the person operating a noise-making machine, but all those close-by

and not only causes noise-induced hearing loss, but also masks other sounds

that are important for communication and for safety.

Pneumatic hammers, many hand tools and earth-moving and other large mobile

machines also subject workers to segmental and whole-body vibration.

Heat and cold hazards arise primarily because a large portion of construction

work is conducted while exposed to the weather, the principal source of

heat and cold hazards. Roofers are exposed to the sun, often with no protection,

and often must heat pots of tar, thus receiving both heavy radiant and

convective heat loads in addition to metabolic heat from physical labor.

Heavy equipment operators may sit beside a hot engine and work in an enclosed

cab with windows and without ventilation. Those that work in an open cab

with no roof have no protection from the sun. Workers in protective gear,

such as that needed for removal of hazardous waste, may generate metabolic

heat from hard physical labor and get little relief since they may be

in an airtight suit. A shortage of potable water or shade contributes

to heat stress as well. Construction workers also work in especially cold

conditions during the winter, with danger of frostbite and hypothermia

and risk of slipping on ice.

The principal sources of non-ionizing ultraviolet (UV) radiation are the

sun and electric arc welding. Exposure to ionizing radiation is less common,

but can occur with x-ray inspection of welds, for example, or it may occur

with instruments such as flow meters that use radioactive isotopes. Lasers

are becoming more common and may cause injury, especially to the eyes,

if the beam is intercepted.

Those who work under water or in pressurized tunnels, in caissons or as

divers are exposed to high barometric pressure. Such workers are at risk

of developing a variety of conditions associated with high pressure: decompression

sickness, inert gas narcosis, aseptic bone necrosis and other disorders.

Strains and sprains are among the most common injuries among construction

workers. These, and many chronically disabling musculoskeletal disorders

(such as tendinitis, carpal tunnel syndrome and low-back pain) occur as

a result of either traumatic injury, repetitive forceful movements, awkward

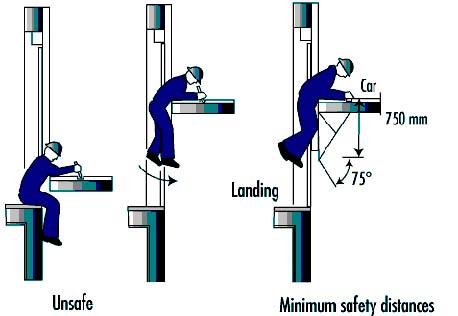

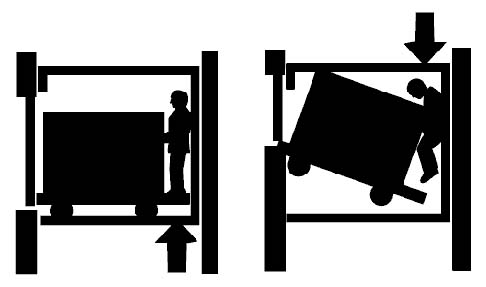

postures or overexertion (see figure 93.1). Falls

due to unstable footing, unguarded holes and slips off scaffolding (see

figure 93.2) and ladders are very common.

Figure

93.1 Carrying without appropriate work clothing and protective equipment

Figure 93.2 Unsafe scaffolding in Kathmandu, Nepal, 1974

Jane Seegal

Biological

hazards

Biological hazards are presented by exposure to infectious microorganisms,

to toxic substances of biological origin or animal attacks. Excavation

workers, for example, can develop histoplasmosis, an infection of the

lung caused by a common soil fungus. Since there is constant change in

the composition of the labor force on any one project, individual workers

come in contact with other workers and, as a consequence, may become infected

with contagious diseases—influenza or tuberculosis, for example.

Workers may also be at risk of malaria, yellow fever or Lyme disease if

work is conducted in areas where these organisms and their insect vectors

are prevalent.

Toxic substances of plant origin come from poison ivy, poison oak, poison

sumac and nettles, all of which can cause skin eruptions. Some wood dusts

are carcinogenic, and some (e.g., western red cedar) are allergenic.

Attacks by animals are rare but may occur whenever a construction project

disturbs them or encroaches on their habitat. This could include wasps,

hornets, fire ants, snakes and many others. Underwater workers may be

at risk from attack by sharks or other fish.

Social hazards

Social hazards stem from the social organization of the industry. Employment

is intermittent and constantly changing, and control over many aspects

of employment is limited because construction activity is dependent on

many factors over which construction workers have no control, such as

the state of an economy or the weather. Because of the same factors, there

can be intense pressure to become more productive. Since the workforce

is constantly changing, and with it the hours and location of work, and

many projects require living in work camps away from home and family,

construction workers may lack stable and dependable networks of social

support. Features of construction work such as heavy workload, limited

control and limited social support are the very factors associated with

increased stress in other industries. These hazards are not unique to

any trade, but are common to all construction workers in one way or another.

Health

Risks of Underground Construction Work

Bohuslav Malek

Hygenic Institute of Prague

Hazards

Underground construction work includes tunneling for roads, highways and

railroads and laying pipelines for sewers, hot water, steam, electrical

conduits, telephone lines. Hazards in this work include hard physical

labour, crystalline silica dust, cement dust, noise, vibration, diesel

engine exhaust, chemical vapours, radon and oxygen-deficient atmospheres.

Occasionally this work must be done in a pressurized environment. Underground

workers are at risk for serious and often fatal injuries. Some hazards

are the same as those of construction on the surface, but they are amplified

by working in a confined environment. Other hazards are unique to underground

work. These include being struck by specialized machinery or being electrocuted,

being buried by roof falls or cave-ins and being asphyxiated or injured

by fires or explosions. Tunneling operations may encounter unexpected

impoundments of water, resulting in floods and drowning.

The construction of tunnels requires a great deal of physical effort.

Energy expenditure during manual work is usually from 200 to 350 W, with

a great part of static load of the muscles. Heart rate during work with

compressed-air drills and pneumatic hammers reaches 150 to 160 per minute.

Work is often done in unfavorable cold and humid microclimatic conditions,

sometimes in cumbersome work postures. It is usually combined with exposure

to other risk factors which depend on the local geological conditions

and on the type of technology used. This heavy workload can be an important

contribution to heat stress.

The need for heavy manual labour can be reduced by mechanization. But

mechanization brings its own hazards. Large and powerful mobile machines

in a confined environment introduce risks of serious injury to persons

working nearby, who may be struck or crushed. Underground machinery also

may generate dust, noise, vibration and diesel exhaust. Mechanization

also results in fewer jobs, which reduces the number of persons exposed

but at the expense of unemployment and all of its attendant problems.

Crystalline silica (also known as free silica and quartz) occurs naturally

in many different types of rock. Sandstone is practically pure silica;

granite may contain 75%; shale, 30%; and slate, 10%. Limestone, marble

and salt are, for practical purposes, completely free of silica. Considering

that silica is ubiquitous in the earth’s crust, dust samples should

be taken and analyzed at least at the start of an underground job and

whenever the type of rock changes as work progresses through it.

Respirable silica dust is generated whenever silica-bearing rock is crushed,

drilled, ground or otherwise pulverized. The main sources of airborne

silica dust are compressed-air drills and pneumatic hammers. Work with

these tools most often occurs in the fore part of the tunnel and, therefore,

workers in these areas are the most heavily exposed. Dust suppression

technology should be applied in all instances.

Blasting generates not only flying debris, but also dust and nitrogen

oxides. To prevent excessive exposure, the customary procedure is to prevent

re-entry to the affected area until the dust and gases have cleared. A

common procedure is to blast at the end of the last work shift of the

day and to clear out debris during the next shift.

Cement dust is generated when cement is mixed. This dust is a respiratory

and mucous membrane irritant in high concentrations, but chronic effects

have not been observed. When it settles on skin and mixes with sweat,

however, cement dust can cause dermatoses. When wet concrete is sprayed

in place, it too can cause dermatoses.

Noise can be significant in underground construction work. Principal sources

include pneumatic drills and hammers, diesel engines and fans. Since the

underground work environment is confined, there is also considerable reverberant

noise. Peak noise levels can exceed 115 dBA, with time-weighted average

noise exposure equivalent to 105 dBA. Noise-reducing technology is available

for most equipment and should be applied.

Underground construction workers can also be exposed to whole-body vibration

from mobile machinery and to hand-arm vibration from pneumatic drills

and hammers. The levels of acceleration transmitted to the hands from

pneumatic tools can reach about 150 dB (comparable to 10 m/s2). Harmful

effects of hand-arm vibration can be aggravated by a cold and damp working

environment.

If soil is highly saturated with water or if construction is conducted

under water, the work environment may have to be pressurized to keep water

out. For underwater work, caissons are used. When workers in such a hyperbaric

environment make too rapid a transition to normal air pressure, they risk

decompression sickness and related disorders. Since the absorption of

most toxic gases and vapours depends on their partial pressure, more may

be absorbed at higher pressure. Ten ppm of carbon monoxide (CO) at 2 atmospheres

of pressure, for example, will have the effect of 20 PPM CO at 1 atmosphere.

Chemicals are used in underground construction in a variety of ways. For

example, insufficiently coherent layers of rock may be stabilized with

an infusion of urea formaldehyde resin, polyurethane foam or mixtures

of sodium water glass with formamide or with ethyl and butyl acetate.

Consequently, vapours of formaldehyde, ammonia, ethyl or butyl alcohol

or di-isocyanates may be found in the tunnel atmosphere during application.

Following application, these contaminants may escape into the tunnel from

the surrounding walls, and it may therefore be difficult to fully control

their concentrations, even with intensive mechanical ventilation.

Radon occurs naturally in some rock and may leak into the work environment,

where it will decay into other radioactive isotopes. Some of these are

alpha emitters that may be inhaled and increase the risk of lung cancer.

Tunnels constructed in inhabited areas can also be contaminated with substances

from surrounding pipes. Water, heating and cooking gas, fuel oil, petrol

and so on may leak into a tunnel or, if pipes carrying these substances

are broken during excavation, they may escape into the work environment.

The construction of vertical shafts using mining technology poses similar

health problems to those of tunneling In terrain where organic substances

are present, products of microbiological decomposition may be expected.

Maintenance work in tunnels used for traffic differs from similar work

on the surface mainly in the difficulty of installing safety and control

equipment, for example, ventilation for electric arc welding; this may

influence the quality of safety measures. Work in tunnels in which pipelines

for hot water or steam are present is associated with great heat load,

demanding a special regime of work and breaks.

Oxygen deficiency may occur in tunnels either because oxygen is displaced

by other gases or because it is consumed by microbes or by the oxidation

of pyrites. Microbes may also release methane or ethane, which not only

displace oxygen but, in sufficient concentration, may create the risk

of explosion. Carbon dioxide (commonly called blackdamp in Europe) is

also generated by microbial contamination. The atmospheres in spaces which

have been closed for a long time may contain mostly nitrogen, practically

no oxygen and 5 to 15% carbon dioxide.

Blackdamp penetrates into the shaft from the surrounding terrain due to

changes in the atmospheric pressure. The composition of the air in the

shaft may change very quickly—it may be normal in the morning, but

be deficient in oxygen by the afternoon.

Prevention

Prevention of exposure to dust should in the first place be implemented

by technical means, such as wet drilling (and/or drilling with LEV), wetting

of the material before it is pulled down and loaded to the transport,

LEV of mining machines and mechanical ventilation of tunnels. Technical

control measures may not be sufficient to lower the concentration of respirable

dust to an acceptable level in some technological operations (e.g., during

drilling and sometimes also in the case of wet drilling), and therefore

it may be necessary to supplement the protection of the workers engaged

in such operations by the use of respirators.

The efficiency of technical control measures must be checked by monitoring

the concentration of airborne dust. In the case of fibrogenic dust, it

is necessary to arrange the programme of monitoring in such a way that

it allows the registration of the exposure of individual workers. The

individual exposure data, in connection with data about each worker’s

health, are necessary for the assessment of the risk of pneumoconiosis

in particular work conditions, as well as for the assessment of the efficiency

of control measures in the long-run. Last but not least, the individual

registration of exposure is necessary for evaluating the ability of individual

workers to continue in their jobs.

Due to the nature of underground work, protection against noise depends

mostly on the personal protection of hearing. Effective protection against

vibrations, on the other hand, can be achieved only by eliminating or

decreasing the vibration by mechanization of risky operations. PPE is

not effective. Similarly, the risk of diseases due to physical overload

of the upper extremities can be lowered only by mechanization.

Exposure to chemical substances can be influenced by the selection of

appropriate technology (e.g., the use of formaldehyde resins and formamide

should be eliminated), by good maintenance (e.g., of diesel engines) and

by adequate ventilation. Organization and work regime precautions are

sometimes very effective, especially in the case of the prevention of

dermatoses.

Work in underground spaces in which the composition of the air is not

known demands strict adherence to safety rules. Entering such spaces without

isolating breathing apparatuses must not be allowed. The work should be

done only by a group of at least three people—one worker in the underground

space, with breathing apparatus and safety harness, the others outside

with a rope to secure the inside worker. In case of accident it is necessary

to act quickly. Many lives have been lost in efforts to save the victim

of an accident when the safety of the rescuer was disregarded.

Pre-placement, periodic and post-employment preventive medical examinations

are a necessary part of the health and safety precautions for workers

in tunnels. The frequency of periodic examinations and the type and scope

of special examinations (x ray, lung functions, audiometry and so on)

should be individually determined for each workplace and for each job

according to the working conditions.

Prior to groundbreaking for underground work, the site should be inspected

and soil samples should be taken in order to plan the excavation. Once

work is underway, the work site should be inspected daily to prevent roof

falls or cave-ins. The workplace of solitary workers should be inspected

at least twice each shift. Fire suppression equipment should be strategically

placed throughout the underground work site.

Preventive

Health Services in Construction

Pekka Roto, Medicine

Officer

Tampere Regional Institute of Occupational Health

The construction industry forms 5 to 15% of the national economy of most

countries and is usually one of the three industries having the highest

rate of work-related injury risks. The following chronic occupational

health risks are pervasive (Commission of the European Communities 1993):

- Musculoskeletal

disorders, occupational hearing loss, dermatitis and lung disorders

are the most common occupational diseases.

- An increased risk

of respiratory tract carcinomas and mesothelioma caused by asbestos

exposure has been observed in all countries where occupational mortality

and morbidity statistics are available.

- Disorders resulting from improper nutrition, smoking or use of alcohol and drugs are associated especially with migrant workers, a substantial portion of construction employment in many countries.

Preventive health

services for construction workers should be planned with these risks as

priorities.

Types of Occupational Health Services

Occupational health services for construction workers consist of three

main models:

- specialized services

for construction workers

- occupational health

care for construction workers rendered by providers of broad-based occupational

health services

- health services provided voluntarily by the employer.

Specialized services are the most effective but also the most expensive

in terms of direct costs. Experiences from Sweden indicate that the lowest

injury rates on construction sites worldwide and a very low risk for occupational

diseases among construction workers are associated with extensive preventive

work through specialized service systems. In the Swedish model, called

Bygghälsan, technical and medical prevention have been combined.

Bygghälsan operates through regional centres and mobile units. During

the severe economic recession of the late 1980s, however, Bygghälsan

severely cut back its health service activities.

In countries that have occupational health legislation, construction companies

usually buy the needed health services from companies serving general

industries. In such cases, the training of occupational health personnel

is important. Without special knowledge of the circumstances surrounding

construction, medical personnel cannot provide effective preventive occupational

health programs for construction companies.

Some large multinational companies have well-developed occupational safety

and health program that are part of the culture of the enterprise. The

cost-benefit calculations have proved these activities economically profitable.

Nowadays, occupational safety program are included in quality management

of most international companies.

Mobile health

clinics

Because construction sites are often situated far from any established

providers of health services, mobile health service units may be necessary.

Practically all countries that have specialized occupational health services

for construction workers use mobile units for delivering the services.

The mobile unit’s advantage is the saving of work time by bringing

the services to worksites. Mobile health centres are contained in a specially

equipped bus or trailer and are especially suitable for all types of screening

procedures, such as periodic health examinations. Mobile services should

be careful to arrange in advance for collaboration with local providers

of health services in order to secure follow-up evaluation and treatment

for workers whose test results suggest a health problem.

Standard equipment for a mobile unit includes a basic laboratory with

a spirometer and an audiometer, an interview room and x-ray equipment,

when needed. It is best to design module units as multipurpose spaces

so they can be used for different types of projects. The Finnish experience

indicates that mobile units are also suitable for epidemiological studies,

which can be incorporated into occupational health program, if properly

planned in advance.

Contents of

preventive occupational health services

Identification of risk at construction sites should guide medical activity,

although this is secondary to prevention through proper design, engineering

and work organization. Risk identification requires a multidisciplinary

approach; this requires close collaboration between the occupational health

personnel and the enterprise. A systematic workplace survey of risks using

standardized checklists is one option.

Preplacement and periodic health examinations are usually conducted according

to requirements set by legislation or guidance provided by authorities.

The examination’s content depends on the exposure history of each

worker. Short work contracts and frequent turnover of the construction

workforce can result in “missed” or “inappropriate”

health examinations, a failure to follow up on findings or unwarranted

duplication of health examinations. Therefore, regular standard periodic

examinations are recommended for all workers. A standard health examination

should contain: an exposure history; symptom and illness histories with

special emphasis on musculoskeletal and allergic diseases; a basic physical

examination; and audiometry, vision, spirometry and blood pressure tests.

The examinations should also provide health education and information

on how to avoid occupational risks known to be common.

Musculoskeletal

disorders and their prevention

Musculoskeletal disorders have multiple origins. Lifestyle, hereditary

susceptibility and aging, combined with improper physical strain and minor

injuries, are commonly accepted risk factors for musculoskeletal disorders.

The types of musculoskeletal problems have different exposure patterns

in different construction professions.

There is no reliable test to predict an individual’s risk for acquiring

a musculoskeletal disorder. Medical prevention of musculoskeletal disorders

is based on guidance in ergonomic matters and lifestyles. Preplacement

and periodic examinations can be used for this purpose. Nonspecific strength

testing and routine x rays of the skeletal system have no specific value

for prevention. Instead, early detection of symptoms and a detailed work

history of musculoskeletal symptoms can be used as a basis for medical

counseling. A program that performs periodic symptom surveys to identify

work factors that can be changed has been shown to be effective.

Often, workers who have been exposed to heavy physical loads or strain

think the work keeps them fit. Several studies have proved that this is

not the case. Therefore, it is important that, in the context of health

examinations, the examinees be informed about proper ways to maintain

their physical fitness. Smoking has also been associated with lumbar disk

degeneration and low-back pain. Therefore, anti-smoking information and

therapy should be included in the periodic health examinations, too (Workplace

Hazard and Tobacco Education Project 1993).

Occupational noise-induced hearing loss

The prevalence of noise-induced hearing loss varies among construction

occupations, depending on levels and duration of exposure. In 1974, less

than 20% of Swedish construction workers at age 41 had normal hearing

in both ears. Implementation of a comprehensive hearing conservation program

increased the proportion in that age group having normal hearing to almost

40% by the late 1980s. Statistics from British Columbia, Canada, show

that construction workers generally suffer significant loss of hearing

after working more than 15 years in the trades (Schneider et al. 1995).

Some factors are thought to increase susceptibility to occupational hearing

loss (e.g., diabetic neuropathy, hypercholesterolemia and exposure to

certain ototoxic solvents). Whole-body vibration and smoking may have

an additive effect.

A large-scale program for hearing conservation is advisable for the construction

industry. This type of program requires not only collaboration at the

worksite level, but also supportive legislation. Hearing conservation

program should be specific in work contracts.

Occupational hearing loss is reversible in the first 3 or 4 years after

initial exposure. Early detection of hearing loss will provide opportunities

for prevention. Regular testing is recommended to detect the earliest

possible changes and to motivate workers to protect themselves. At the

time of testing, the exposed workers should be educated in the principles

of personal protection, as well as the maintenance and proper use of protection

devices.

Occupational dermatitis

Occupational dermatitis is prevented mainly by hygienic measures. The

proper handling of wet cement and skin protection are effective in promoting

hygiene. During health examinations, it is important to stress the importance

of avoiding skin contact with wet cement.

Occupational lung diseases

Asbestosis, silicosis, occupational asthma and occupational bronchitis

can be found among construction workers, depending on their past work

exposures (Finnish Institute of Occupational Health 1987).

There is no medical method to prevent the development of carcinomas after

someone has been sufficiently exposed to asbestos. Regular chest x rays,

every third year, are the most common recommendation for medical surveillance;

there is some evidence that x-ray screening improves the outcome in lung

cancer (Strauss, Gleanson and Sugarbaker 1995). Spirometry and anti-smoking

information are usually included in the periodic health examination. Diagnostic

tests for the early diagnosis of asbestos-related malignant tumors are

not available.

Malignant tumors and other lung diseases related to asbestos exposure

are widely underdiagnosed. Therefore, many construction workers eligible

for compensation remain without benefits. In the late 1980s and early

1990s, Finland conducted a nationwide screening of workers exposed to

asbestos. The screening revealed that only one-third of the workers with

asbestos-related diseases and who had access to occupational health services

had been diagnosed earlier (Finnish Institute of Occupational Health 1994).

Special needs of migrant workers

Depending on the construction site, the social context, sanitary conditions

and climate may present important risks to construction workers. Migrant

workers often suffer from psychosocial problems. They have a higher risk

of work-related injuries than native workers. Their risk of carrying infectious

diseases, such as HIV/AIDS, tuberculosis, and parasitic diseases must

be taken into account. Malaria and other tropical diseases are problems

for workers in areas where they are endemic.

In many large construction projects, a foreign workforce is used. A preplacement

medical examination should be conducted in the home country. Also, the

spreading of contagious diseases must be prevented through proper vaccination

program In the host countries, proper vocational training, health and

safety education, and housing should be organized. Migrant workers should

be provided the same access to health care and social security as native

workers (El Batawi 1992).

In addition to preventing construction-related ailments, the health practitioner

should work to promote positive changes in lifestyle, which can improve

a worker’s health overall. Avoiding alcohol and smoking are the most

important and fruitful themes for health promotion for construction workers.

It has been estimated that a smoker costs the employer 20 to 30% more

than a nonsmoking worker. Investments in anti-smoking campaigns pay not

only in the short term, with lower accident risks and shorter sick leaves,

but also in the long term, with lower risks of cardiovascular pulmonary

diseases and cancer. In addition, tobacco smoke has harmful multiplier

effects with most dusts, especially with asbestos.

Economic benefits

It is difficult to prove any direct economic benefit of occupational health

services to an individual construction company, especially if the company

is small. Indirect cost-benefit calculations show, however, that accident

prevention and health promotion are economically beneficial. Cost-benefit

calculations of investments in preventive program are available for companies

to use internally. (For a model used extensively in Scandinavia, see Oxenburg

1991.)

Health

and Safety Regulations: The Netherlands Experience

Leen Akkers, Managing

Director

Stichting Arbouw

Implementation of

the EC directive Minimum Regulations for Health and Safety on Temporary

and Mobile Building Sites typifies the legal regulations emanating from

the Netherlands and from the European Union. Their aim is to improve working

conditions, to combat disability and to reduce sickness absenteeism. In

the Netherlands, these regulations for the construction industry are expressed

in the Arbouw Resolution, Chapter 2, Section 5.

As is often the case, the legislation seems to be following the social

changes that began in 1986, when organizations of employers and employees

joined to establish the Arbouw Foundation to provide services for construction

companies in civil engineering and utility construction, earth works,

roadbuilding and water construction and the completion sectors of the

industry. Thus, the new regulations are scarcely a problem for the responsible

companies already committed to implement health and safety considerations.

The fact that these principles are often very difficult to put into practice,

however, has led to non-observance and unfair competition and, consequently,

the need for legal regulations.

Legal Regulations

The legal regulations focus on preventive measures before the construction

project is started and while it is in progress. This will yield the greatest

long-term benefit.

The Health and Safety Act stipulates that evaluations of risks must address

not only those arising from materials, preparations, tools, equipment

and so on, but also those involving special groups of workers (e.g., pregnant

women, young and elderly workers and those with disabilities).

Employers are obliged to have written risk evaluations and inventories

produced by certified experts, who may be employees or external contractors.

The document must include recommendations for eliminating or limiting

the risks and must also stipulate phases of the work when qualified specialists

will be required. Some construction companies have developed their own

approach to the evaluation, the General Business Investigation and Risk

Inventory and Evaluation (ABRIE), which has become the prototype for the

industry.

The Health and Safety Act obliges employers to offer a periodic health

examination to their employees. The purpose is to identify health problems

that may make certain jobs especially hazardous for some workers unless

certain precautions are taken. This requirement echoes the various collective

labor agreements in the construction industry which for years have required

employers to provide employees with comprehensive occupational health

care, including periodic medical examinations. The Arbouw Foundation has

contracted with the Federation of Occupational Health and Safety Care

Centres for the provision of these services. Over the years, a wealth

of valuable information has been accumulated which has contributed to

enhancement of the quality of the risk inventories and evaluations.

Absenteeism Policy

The Health and Safety Act also requires employers to have an absenteeism

policy which includes a stipulation that experts in this field be retained

to monitor and counsel disabled employees.

Joint Responsibility

Many health and safety risks can be traced to inadequacies in the building

and organization choices or to poor planning of the work when setting

up a project. To obviate this, the employers, employees and the government

agreed in 1989 on a working conditions covenant. Among other things, it

specified cooperation between clients and contractors and between contractors

and subcontractors. This has resulted in a code of conduct which serves

as a model for the implementation of the European directive on temporary

and mobile building sites.

As part of the covenant, Arbouw formulated limits for exposure to hazardous

substances and materials, along with guidelines for the application in

various construction operations.

Under the leadership of Arbouw, the FNV Building Workers and Wood Workers

Union, the FNV Industry Union and the Mineral Wool Association, Benelux,

agreed to a contract that called for the development of glass wool and

mineral wool products with less dust emission, development of the safest

possible production methods for glass wool and mineral wool, formulation

and promotion of working methods for the safest use of these products

and performance of the research necessary to establish safe exposure limits

to them. The exposure limit for respirable fibers was set at 2/cm3

although a limit of 1/cm3 was regarded as feasible. They also

agreed to eliminate the use of raw and secondary materials that are health

risks, using as criteria the exposure limits formulated by Arbouw. Performance

under this agreement will be monitored until it expires on 1 January 1999.

Construction Process Quality

The implementation of the EC directive does not stand in isolation but

is an integral part of company health and safety policies, along with

quality and environmental policies. Health and safety policy is critical

part of the quality policy of the companies. The laws and regulations

will be enforceable only if the employers and employees of the construction

industry have played a role in their development. The government has dictated

the development of a model health and safety plan that is practicable

and can be enforced to prevent unfair competition from companies that

ignore or subvert it.

Organizational

Factors Affecting Health and Safety

Doug J. McVitte, Manager

Technical Services

Construction Safety Association of Ontario

Diversity of Projects

and Work Activities

Many people outside the construction industry are unaware of the diversity

and degree of specialization of work undertaken by the industry, though

they see portions of it every day. In addition to traffic delays caused

by encroachments on roads and street excavations, the public is frequently

exposed to buildings being erected, subdivisions being constructed and,

occasionally, to the demolition of structures. What is hidden away from

view, in most cases, is the large amount of specialized work done either

as part of a “new” construction project or as part of the ongoing

repairs maintenance associated with almost anything constructed in the

past.

The list of activities is very diverse, ranging from electrical, plumbing,

heating and ventilating, painting, roofing and flooring work to very specialized

work such as installing or repairing overhead doors, setting heavy machinery,

applying fireproofing, refrigeration work and installing or testing communications

systems.

The value of construction can be partially measured by the value of building

permits. Table 93.4 shows the value of construction

in Canada in 1993.

Table

93.4 Value of construction projects in Canada, 1993 (based on value of

building permits issued in 1993)

| Type of Project | Value ($ Cdn) | % of total |

| Residential building (houses, apartments) | 38,432,467,000 | 40.7 |

| Industrial buildings (factories, mining plants) | 2,594,152,000 | 2.8 |

| Commercial buildings (offices, stores, shops etc.) | 11,146,469,000 | 11.8 |

| Institutional buildings (schools, hospitals) | 6,205,352,000 | 6.6 |

| Other buildings (airports, bus stations, farm buildings, etc.) | 2,936,757,000 | 3.1 |

| Marine facilities (wharves, dredging) | 575,865,000 | 0.6 |

| Roads and highways | 6,799,688,000 | 7.2 |

| Water and sewage systems | 3,025,810,000 | 3.2 |

| Dams and irrigation | 333,736,000 | 0.3 |

| Electric power (thermal/nuclear/hydro) | 7,644,985,000 | 8.1 |

| Railway, telephone, telegraph | 3,069,782,000 | 3.2 |

| Gas and oil (refineries, pipelines) | 8,080,664,000 | 8.6 |

| Other engineering construction (bridges, tunnels, etc.) | 3,565,534,000 | 3.8 |

| Total | 94,411,261,000 | 100 |

The health and safety aspects of the work depend in large measure on the nature of the project. Each type of project and each work activity presents different hazards and solutions. Often, the severity, scope or size of the problem is related to the size of the project as well.

Client-Contractor

Relationships

Clients are the individuals, partnerships, corporations or public authorities

for whom construction is carried out. The vast majority of construction

is done under contractual arrangements between clients and contractors.

A client may select a contractor based on past performance or through

an agent such as an architect or engineer. In other cases, it may decide

to offer the project through advertising and tendering. The methods used

and the client’s own attitude to health and safety can have a profound

effect on the project’s health and safety performance.

For example, if a client chooses to “pre-qualify” contractors

to ensure that they meet certain criteria, then this process excludes

inexperienced contractors, those who may not have had satisfactory performance

and those without qualified personnel required for the project. While

health and safety performance has not previously been one of the common

qualifications sought or considered by clients, it is gaining in usage,

primarily with large industrial clients and with government agencies that

purchase construction services.

Some clients promote safety much more than others. In some cases, this

is due to the risk of damage to their existing facilities when contractors

are brought in to perform maintenance or to expand the client’s facilities.

Petrochemical companies in particular make it clear that contractor safety

performance is a key condition of the contract.

Conversely, those firms who choose to offer their project through an unqualified

open bidding process to obtain the lowest price often end up with contractors

that may be unqualified to perform the work or who take short cuts to

save on time and materials. This can have an adverse effect on health

and safety performance.

Contractor-Contractor Relationships

Many people who are not familiar with the nature of the contractual arrangements

common in construction presume that one contractor performs all or at

least the major part of most building construction. For example, if a

new office tower, sports complex or other high-visibility project is being

constructed, the general contractor usually erects signs and often company

flags to indicate its presence and to create the impression that this

is “its project”. Years ago, this impression may have been relatively

accurate, since some general contractors actually undertook to perform

substantial parts of the project with their own direct-hire forces. However,

since the mid-1970s, many, if not most, general contractors have assumed

more of a project management role on large projects, with the vast majority

of the work contracted out to a network of subcontractors, each of which

has special skills in a particular aspect of the project. (See table

93.5)

Table

93.5 Contractors/subcontractors on typical industrial/commercial/institutional

projects

| Project manager/general

contractor

Excavating contractor Formwork contractor Reinforcing steel contractor Structural steel contractor Electrical contractor Plumbing contractor Drywall contractor Painting contractor Glazing contractor Masonry contractor Finish carpentry/cabinet work contractor Flooring contractor Heating/ventilation/air conditioning contractor Roofing contractor Landscaping contractor |

As a result, the

general contractor could actually have fewer staff onsite than any of

several subcontractors on the project. In some cases the main contractor

has no workforce directly involved in construction activities, but manages

the work of subcontractors. On most major projects in the industrial,

commercial and institutional (ICI) sector, there are several layers of

subcontractors. Typically, the primary level of subcontractors have contracts

with the general contractor. However, these subcontractors may contract

part of their work out to other smaller or more specialized subcontractors.

The influence that this network of contractors may have on health and

safety becomes fairly obvious when it is compared with a fixed worksite

such as a factory or a mill. At a typical fixed-industry workplace, there

is only one management entity, the employer. The employer has sole responsibility

for the workplace, the lines of command and communication are simple and

direct, and only one corporate philosophy applies. At a construction project,

there may be ten or more employer entities (representing the general contractor

and the usual subcontractors), and the lines of communication and authority

tend to be more complex, indirect and often confused.

The attention given to health and safety by the person or company in charge

can influence the health and safety performance of others. If the general

contractor has attached a high degree of importance to health and safety,

this can have a positive influence on the health and safety performance

of the subcontractors on the project. The converse is also true.

Additionally, the overall health and safety performance of the site can

be adversely affected by the performance of one subcontractor (e.g., if

one subcontractor has poor housekeeping, leaving a mess behind as his

or her forces move through the project, it can create problems for all

of the other subcontractors onsite).

Regulatory efforts regarding health and safety are generally more difficult

to introduce and administer in these multi-employer workplaces. It may

be difficult to determine which employer has responsibility for which

hazards or solutions, and any administrative controls which appear to

be eminently workable in a single-employer workplace may need significant

modification to be workable on a multi-employer construction project.

For example, information regarding hazardous materials used on a construction

project must be communicated to those who work with or near the materials,

and workers must be adequately trained. At a fixed workplace with only

one employer, all of the material and the information accompanying it

is much more readily obtained, controlled and communicated, whereas on

a construction project, any of the various subcontractors may be bringing

in hazardous materials of which the general contractor has no knowledge.

Additionally, workers employed by one subcontractor using a certain material

may have been trained, but the crew working for another subcontractor

in the same area but doing something entirely different may know nothing

about the material and yet could be as much at risk as those using the

material directly.

Another factor which emerges regarding contractor-contractor relationships

relates to the bidding process. A subcontractor who bids too low may take

shortcuts that compromise health and safety. In these cases, the general

contractor must ensure that subcontractors adhere to the standards, specifications

and statutes pertaining to health and safety. It is not uncommon on projects

where everyone has bid very low to observe continuing health and safety

problems coupled with excessive passing of responsibility, until regulatory

authorities step in to impose a solution.

A further problem relates to the scheduling of work and the impact this

can have on health and safety. With several different subcontractors on

the site at one time, competing interests may create problems. Each contractor

wants to get his or her work done as quickly as possible. When two or

more contractors want to occupy the same space, or when one has to perform

work overhead of another, problems can occur. This is typically a much

more common problem in construction than in fixed industry, where the

main competing interests tend to involve only operations versus maintenance.

Employer-Employee

Relationships

The several employers on a particular project may have somewhat different

relationships with their employees than those common at most fixed industrial

workplaces. For example, unionized workers at a manufacturing facility

tend to belong to one union. When the employer needs additional workers,

it interviews and hires them and the new employees join the union. Where

there are former unionized workers on layoff, they are rehired generally

on a seniority basis.

In the unionized part of the construction industry, a completely different

system is used. Employers form collective associations which then enter

into agreements with building and construction trade unions. The majority

of the non-salaried direct-hire employees in the industry work through

their union. When, for example, a contractor needs five additional carpenters

at a project, he or she would call the local Carpenters’ Union and

place a request for five carpenters to show up for work at the project

on a certain day. The union would notify the five members at the top of

the employment list that they are to report to the project to work for

the particular firm. Depending on the provisions of the collective agreement

between the employers and the union, the contractor may be able to “name

hire” or select some of these workers. If there are no union members

available to fill the employment call, the employer may be able to hire

temporary workers who would join the union, or the union may bring in

skilled workers from other locals to help fill the demand.

In non-unionized situations, employers use different processes to obtain

additional staff. Prior employment lists, local employment centres, word

of mouth and advertising in local newspapers are the principal methods

used.

It is not uncommon for workers to be employed by several different employers

in the course of a year. The employment duration varies with the nature

of the project and the amount of work to be done. This places a large

administrative load on the construction contractors compared with their

fixed-industry counterparts (e.g., recordkeeping for income taxes, workers’

compensation, unemployment insurance, union dues, pensions, licensing

and other regulatory or contractual issues).

This situation presents some unique challenges compared to the typical

fixed-industry workplace. Training and qualifications must not only be

standardized but portable from one job or sector to another. These important

issues affect the construction industry much more profoundly than fixed

industries. Construction employers expect workers to come to the project

with certain skills and capabilities. In most trades, this is accomplished

by a comprehensive apprenticeship program. If a contractor places a call

for five carpenters, he or she expects to see five qualified carpenters

at the project on the day they are needed. If health and safety regulations

require special training, the employer needs to be able to access a pool

of workers with this training, since the training may not be readily available

at the time the work is scheduled to start. An example of this is the

Certified Worker Program required at larger construction projects in Ontario,

Canada, which involves having joint health and safety committees. Since

this training is not currently part of the apprenticeship program, alternative

training systems had to be put in place to create a pool of trained workers.

With growing emphasis on specialized training or at least confirmation

of skill level, training program conducted in conjunction with the building

and construction trades unions will likely grow in importance, number

and variety.

Inter-union Relationships

The structure of organized labor mirrors the way in which contractors

have specialized within the industry. On a typical construction project,

five or more trades may be represented onsite at any one time. This involves

many of the same problems posed by multiple employers. Not only are there

competing interests to deal with, but lines of authority and communication

are more complex and sometimes blurred when compared with a single-employer,

single-union workplace. This influences many aspects of health and safety.

For example, which worker from which union will represent all workers

on the project if there is a regulatory requirement for a health and safety

representative? Who gets trained in what and by whom?

In the case of rehabilitation and reinstatement of injured workers, the

options for skilled construction workers are much more limited than those

of their fixed-industry counterparts. For example, an injured worker at

a factory may be able to return to some other job at that workplace without

crossing important jurisdictional boundaries between one union and another,

because there is typically only one union in the factory. In construction,

each trade has fairly clearly defined jurisdiction over the types of work

its members can perform. This greatly limits the options for injured workers

who may not be able to perform their normal pre-injury job functions but

could none the less perform some other related work at that workplace.

Occasionally, jurisdictional disputes arise over which union should perform

certain types of work which have health and safety implications. Examples

include scaffold erection, boom truck operation, asbestos removal and

rigging. Regulations in these areas need to consider jurisdictional concerns,

especially with respect to licensing and training.

The Dynamic Nature of Construction

Construction workplaces are in many respects quite different from fixed

industry. Not only are they different, they tend to be constantly changing.

Unlike a factory which operates at a given location day after day, with

the same equipment, the same workers, the same processes and generally

the same conditions, construction projects evolve and change from day

to day. Walls are erected, new workers from different trades arrive, materials

change, employers change as they complete their portions of the work,

and most projects are affected to some degree just by the changes in the

weather.

When one project is completed, workers and employers move on to other

projects to start all over again. This indicates the dynamic nature of

the industry. Some employers work in several different cities, provinces,

states or even countries. Similarly, many skilled construction workers

move with the work. These factors influence many aspects of health and

safety, including workers’ compensation, health and safety regulations,

performance measurement and training.

Summary

The construction industry is presented with some very different conditions

from those in fixed industry. These conditions must be considered when

control strategies are being contemplated and may help to explain why

things are done differently in the construction industry. Solutions developed

with the input from both construction labor and construction management,

who know these conditions and how to deal effectively with them, offer

the best chance for improving health and safety performance.

Integrating

Prevention and Quality Management

Rudolf Scholbeck,

Head

International Labour Office

Improving Occupational

Health and Safety

Construction companies are increasingly adopting the quality management

systems spelled out by the International Organization for Standardization

(ISO), such as the ISO 9000 series and the subsequent regulations that

have been based on it. Although no recommendations on occupational health

and safety are specified in this set of standards, there are cogent reasons

for including preventive measures when implementing a management system

such as that required by the ISO 9000.

Occupational health and safety regulations are written and implemented

and are continuously being adapted to technological progress as well as

to new safety techniques and to advances in occupational medicine. All

too often, however, they are not followed, either deliberately or out

of ignorance. When this occurs, models for safety management, such as

the ISO 9000 series, assist in integrating the structure and content of

preventive measures into management. The advantages of such a comprehensive

approach are obvious.

Integrated management means that occupational health and safety regulations

are no longer looked at in isolation, but gain relevance from the corresponding

sections of a quality management handbook, as well as in process and work

instructions, thus creating a fully integrated system. This integral approach

can improve the chances of greater attention to accident prevention measures

in daily construction practice and, thereby, reduce the number of workplace

accidents and injuries. Dissemination of a handbook that integrates occupational

health and safety procedures into the processes it describes is crucial

for this process.

New management methods are aimed at putting people closer to the centre

of the processes. Coworkers are being more actively involved. Information,

communication and cooperation are promoted across hierarchical barriers.

The reduction of absences due to illness or workplace accidents enhances

the implementation of the principles of quality management in construction.

With the development of new building methods and equipment, safety requirements

increase steadily in number. The increasing concern with environmental

protection makes the problem even more complex. Coping with the demands

of modern prevention is difficult without appropriate regulations and

a centrally directed articulation of the process and work instructions.

Clear divisions of responsibility and effective coordination for the prevention

plan should, therefore, be written into the quality management system.

Improving Competitiveness

Documentation of the existence of an occupational safety management system

is increasingly required when contractors submit bids for work, and its

effectiveness has become one of the criteria for awarding a contract.

The pressure of international competition could become even greater in

the future. It seems prudent, therefore, to integrate preventive measures

into the quality management system now, rather than waiting and being

forced by increasing competitive pressure to do so later, when the pressure

of time and the costs of personnel and financing will be much greater.

Furthermore, a not inconsiderable benefit of an integrated prevention/quality

management system is that having such a well-documented program in place

is likely to reduce the costs of coverage, not only for workers’

compensation, but also for product liability.

Company Management

Company management must be committed to the integration of occupational

health and safety into the management system. Goals specifying the content

and time-frame of this effort should be defined and included in the basic

statement of company policy. The necessary resources should be made available

and appropriate personnel assigned to accomplish the project goals. Specialized

safety personnel are generally required in large and mid-sized construction

companies. In smaller companies, the employer must take the responsibility

for the preventive aspects of the quality management system.

A periodic company management review closes the circle. The collective

experiences in utilizing the integrated prevention/ quality management

system should be examined and assessed, and plans for revision and for

subsequent review should be formulated by company management.

Assessing Results

Assessment of results of the occupational safety management system that

has been instituted is the second step in the integration of preventive

measures and quality management.

The dates, kinds, frequency, causes and costs of accidents should be compiled,

analyzed and shared with all those in the company with relevant responsibilities.

Such an analysis enables the company to set priorities in formulating

or modifying process and work instructions. It also makes clear the extent

to which occupational health and safety experience affects all divisions

and all processes in the construction company. For this reason, defining

the interface between company processes and preventive aspects takes on

great importance. During bid preparation, the resources in time and money

needed for comprehensive preventive measures, such as those incurred in

clearing debris, can be precisely calculated.

When purchasing construction materials, attention should be paid to the

availability of substitutes for potentially dangerous materials. From

the beginning of a project responsibility for occupational health and

safety should be assigned for particular aspects and each phase of the

construction project. The need and availability for special training in

occupational health and safety as well as the relative risks of injury

and disease should be compelling considerations in the adoption of particular

construction processes. These conditions must be recognized early on so

that appropriately qualified workers can be selected and the courses of

instruction can be arranged in a timely manner.

The responsibilities and authorities of the personnel assigned to safety

and how they fit into the daily work should be documented in writing and

collated with the onsite task descriptions. The construction company’s

occupational safety staff should appear shown in its organizational chart,

which, along with a clear responsibility matrix and schematic flowcharts

of processes, should appear in the quality management handbook.

An Example

from Germany

In practice, there are four formal procedures and their combinations for

integrating occupational health and safety into a quality management system

that have been implemented in Germany:

- A quality management handbook and a separate occupational safety management handbook are developed. Each has its own procedures and work instructions. In extreme cases, this creates ineffective, insular organizational solutions, which require twice the amount of work and in practice do not accomplish the desired results.

- An additional section is inserted into the quality management handbook with the heading “Occupational health and safety”. All statements on occupational health and safety are organized in this section. This path is chosen by some construction companies. Positioning a health and safety problem in a separate section may well highlight the importance of prevention, but it entails the risk being ignored as a “fifth wheel” and serves more as an evidence of intent rather than a command for appropriate action.

- All aspects of occupational health and safety are worked directly into the quality management system. This is the most systematic implementation of the basic idea of integration. The integrated and flexible structuring of the presentation models of the German DIN EN ISO 9001-9003 permits such an inclusion.

- The Underground Construction Trade Organization (Berufs-genossenschaft) favors a modular integration. This concept is explained below.

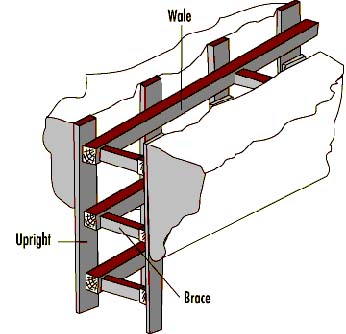

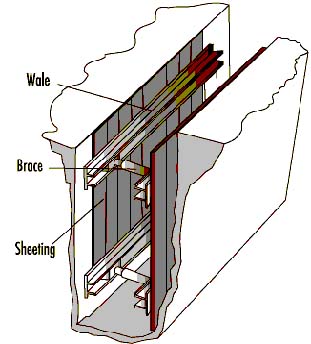

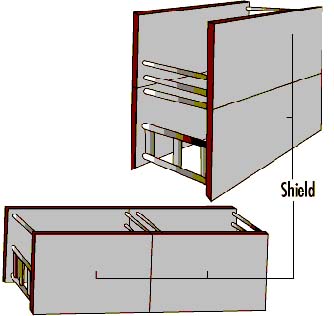

Once the assessment is completed, at the latest, those responsible for the construction project should contact the quality management officers and decide on the steps for actually integrating occupational safety into the management system. Comprehensive preparatory work should facilitate setting common priorities during the work that promise the greatest preventive results.