Summary Statement

This September 2012 Safety Flash from Day & Zimmerman warns about small cracks in the side rails of a fiberglass extension ladder that was less than 2 months old and had been inspected. The 30-foot Type 1A extension ladder was being used to access the roof of a building when it collapsed. This document provides information on the near miss that resulted and outlines steps employers and worker should take when inspecting fiberglass ladders before use.

September 18, 2012

Safety Flash No.: SF2012-022

Location: Westar

Issue Date: 9/18/12

Ladder Inspections ‐ Why they are so Important

Two roofing technicians were going on to a flat roof to perform an inspection and repair. The first technician set up a 30 foot extension ladder to access the roof. The ladder was a Type IA Fiberglass ladder rated for a load capacity of 300 pounds. The technician weighed approximately 160 pounds. The ladder had been inspected and was less than 2 months old. The ladder had not been damaged or subjected to any harsh conditions.

As the technician was climbing the ladder he felt the ladder start to give from underneath him. He was able to reach and hold on to the roof edge as the ladder collapsed. The second technician was able to get another ladder from their service truck, set the ladder up and get the first technician down safely without incident.

Ladder collapsed – worker was able to grab on to the leading edge of the building

The lower section of the ladder failed

Investigation

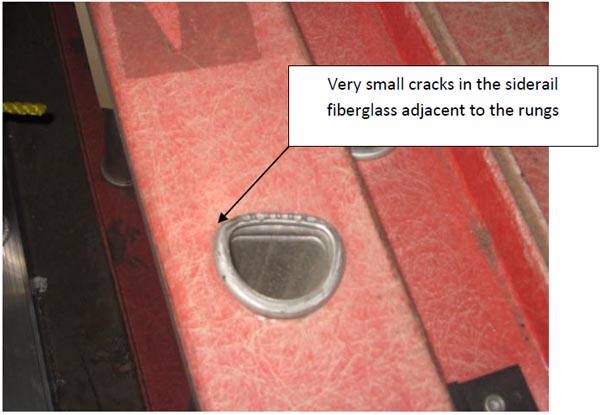

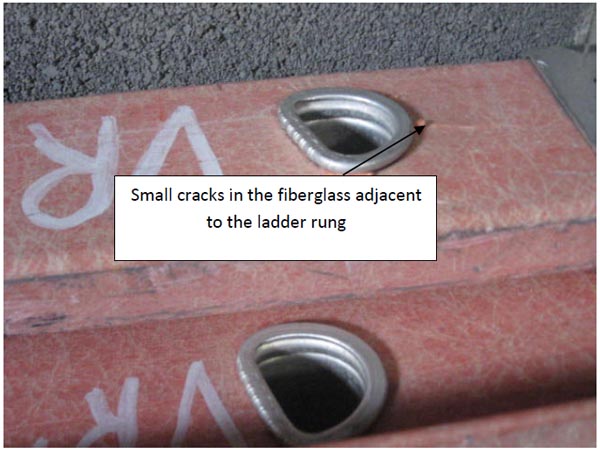

All fiberglass ladders were immediately brought in from the field and closely examined for any possible defects or damage. The company found that on approximately 20% of their fiberglass extension ladders there were very small cracks in the fiberglass on the siderails immediately next to the rungs of some ladders.

In addition to the small cracks in the fiberglass in some areas the fiberglass material had split.

Follow‐up

The small cracks found in the siderails of the extension ladders were not noted to be in any pattern along the siderail. The cracks and splits in the fiberglass were found to be immediately next to the rungs on the outside portion of the siderail.

Currently it is believed the fiberglass may have been damaged or fatigued during the manufacturing process when the rungs were crimped into the siderail of the ladder.

Recommendations

The small cracks around the rungs are not easily detected by a quick visual inspection. Workers need to ‘feel’ with their finger tips for any raised spots in the fiberglass and remove any debris along the side rails in the areas where the rungs are crimped to check for small cracks or splits. The cracks were not found in any pattern or specific location on all the ladders inspected. It is important to inspect each rung on both the exterior and interior side of the siderail for any signs of cracks or splits in the fiberglass.

Any fiberglass ladder with these small cracks should be removed from service.