OSHA Hazard Alert: Working Safely with Scissor Lifts

Summary Statement

Scissor lifts provide a safe and reliable platform for workers to perform job tasks when used according to the manufacturer’s instructions. When not used properly, scissor lifts can present a serious hazard to workers. This OSHA Hazard Alert highlights specific hazards present in workplaces where scissor lifts are used and controls employers must implement to prevent injuries or fatalities.

2016

Introduction

Scissor lifts are work platforms used to safely move workers vertically and to different locations in a variety of industries including construction, retail, entertainment and manufacturing. Scissor lifts are different from aerial lifts because the lifting mechanism moves the work platform straight up and down using crossed beams functioning in a scissorlike fashion. Although scissor lifts present hazards similar to scaffolding when extended and stationary, using scissor lifts safely depends on considering equipment capabilities, limitations and safe practices.

Scissor lifts are work platforms used to safely move workers vertically and to different locations in a variety of industries including construction, retail, entertainment and manufacturing. Scissor lifts are different from aerial lifts because the lifting mechanism moves the work platform straight up and down using crossed beams functioning in a scissorlike fashion. Although scissor lifts present hazards similar to scaffolding when extended and stationary, using scissor lifts safely depends on considering equipment capabilities, limitations and safe practices.

Over a one-year period, OSHA investigated ten preventable fatalities and more than 20 preventable injuries resulting from a variety of incidents involving scissor lifts. OSHA’s investigations found that most injuries and fatalities involving scissor lifts were the result of employers not addressing:

- Fall Protection

- Stabilization

- Positioning

How to Safely Use Scissor Lifts

Employers need to assess the worksite to identify all possible hazards in order to select the appropriate equipment for the task. Employers who use scissor lifts need to evaluate and implement effective controls that address fall protection, stabilization and positioning. Only trained workers should be allowed to use scissor lifts, and employers should make sure that those workers show that they can use a scissor lift properly. Safe scissor lift use includes properly maintaining the equipment, following the manufacturer’s instructions, providing workers training and needed personal protective equipment (PPE), and implementing safe work practices.

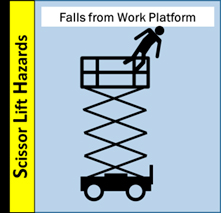

Fall Protection

Scissor lifts must have guardrails installed to prevent workers from falling (see 29 CFR 1926.451(g) or 29 CFR 1910.29(a)(3)(vii)).

Scissor lifts must have guardrails installed to prevent workers from falling (see 29 CFR 1926.451(g) or 29 CFR 1910.29(a)(3)(vii)).

Employers should train workers to:

- Check to see that a guardrail system is in place before working on the scissor lift.

- Only stand on the work platform; never stand on the guardrails.

- Keep work within easy reach to avoid leaning away from the scissor lift.

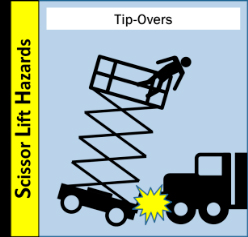

Stabilization

Employers should ensure that scissor lifts are stable and will not tip over or collapse. Some safe work practices to ensure safe, stable conditions for scissor lift use include:

- Follow the manufacturer’s instructions for safe movement—this usually rules out moving the lift in an elevated position.

- Isolate the scissor lift or implement traffic control measures to ensure that other equipment cannot contact the scissor lift.

- Select work locations with firm, level surfaces away from hazards that can cause instability (e.g., dropoffs, holes, slopes, bumps, ground obstructions, or debris).

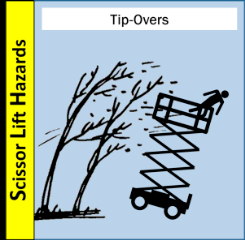

- Use the scissor lift outside only when weather conditions are good. Scissor lifts rated for outdoor use are generally limited to wind speeds below 28 miles per hour.

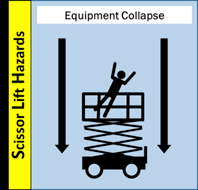

Although rare, the collapse of scissor lifts can be prevented if employers:

- Ensure that safety systems designed to stop collapsing are maintained and not bypassed.

- Never allow the weight on the work platform to exceed the manufacturer’s load rating.

- Never allow equipment other than the scissor mechanism to be used to raise the work platform (e.g., using a forklift to lift the work platform).

- Keep the lift from being struck by other moving equipment on the worksite.

Caution: Wind Can Make Extended Scissor Lifts Unstable

During the Fall 2010 college football season, a student who was also an employee of the University of Notre Dame was killed while filming the school’s football team practice from a scissor lift. Reportedly, the untrained worker raised the lift over 39 feet to film the practice. The wind gusts that day were more than 50 miles per hour. The high winds blew the lift over, killing the worker.Positioning

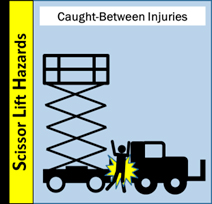

Positioning the scissor lift to avoid crushing or electrocution hazards is important for safe use.

Crushing hazards are present in workplaces using scissor lifts and may expose workers nearby, even those not working on the scissor lift.

Scissor lifts present crushing hazards similar to vehicles and other mobile equipment at worksites. Employers should train workers to be watchful when:

Scissor lifts present crushing hazards similar to vehicles and other mobile equipment at worksites. Employers should train workers to be watchful when:

- A moving scissor lift is near a fixed object.

- A moving vehicle and the scissor lift are operating closely.

- The scissor lift passes under a fixed object, such as a door frame or a support beam.

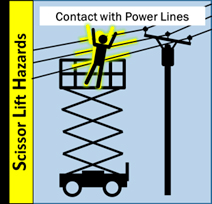

Positioning the scissor lift to avoid electrocution, arc flash, and thermal burns is important for safely using scissor lifts near energized power lines. Since electricity can arc or jump from the power line to the scissor lift or worker, electrocution can occur even if neither the scissor lift nor the worker touches the power line.

Employers should use the following work practices to ensure that scissor lifts are safely positioned:

Employers should use the following work practices to ensure that scissor lifts are safely positioned:

- Implement traffic control measures around the scissor lift to prevent other workers or vehicles from getting too close.

- Use ground guides when operating or moving the scissor lift around the workplace.

- Select work locations that do not approach electrical power sources (e.g., power lines, transformers) by at least 10 feet and that do not pose other overhead hazards (e.g., other utilities, branches, overhangs, etc.).

- If the job task requires work near an electrical source, ensure that the worker is qualified and has received the required electrical training. (29 CFR 1910.269; 29 CFR 1910.333; 29 CFR 1926 Subpart V).

Maintaining Scissor Lifts

Employers must regularly maintain scissor lifts to ensure that they are safe to use (e.g., prevent the lifting mechanism from collapsing). Manufacturer’s maintenance and inspection instructions will generally include how to:

- Test and inspect controls and components before each use.

- Ensure that guardrail systems are in good working condition.

- Verify that brakes once set will hold the scissor lift in position.

Training Workers

Employers must provide workers training on hazards, including how to work safely with or near scissor lifts. (29 CFR 1926.454). Training must, at a minimum, include:

- Manufacturer’s instructions for operating the scissor lift vertically and while in transit.

- How to handle materials on the scissor lift, including weight limits.

- Other worksite hazards workers may encounter when working on a scissor lift (e.g., contact with electrical wires).

- Reporting any equipment defects or maintenance needs.

OSHA Standards

Employers must comply with the following OSHA standards (29 CFR) to protect workers from hazards associated with scissor lifts.

General Industry

- 1910.23 – Guarding Floor and Wall Openings and Holes

- 1910.28 – Safety Requirements for Scaffolding

- 1910.29 – Manually Propelled Mobile Ladder Stands and Scaffolds (Towers)

- 1910.333 – Selection and Use of Work Practices

Shipyards

- 1915.71 – Scaffolds or Staging

Construction

- 1926.21 – Safety Training and Education

- 1926.451 – General Requirements

- 1926.452 – Additional Requirements to Specific Types of Scaffolds

- 1926.454 – Training Requirements

Additional Information

Many scissor lifts are covered under OSHA’s Scaffolding standard. For technical assistance, please refer to OSHA’s eTool and other resources on scaffolding.

The American National Standards Institute (ANSI) has standards for manufacturing, owning and operating scissor lifts. They can be found in ANSI A92.3-2006 (Manually Propelled Elevating Aerial Platforms) and A92.6-2006 (Self-Propelled Elevating Work Platforms).

How OSHA Can Help

OSHA has compliance assistance specialists throughout the nation who can provide information to employers and workers about OSHA standards, short educational programs on specific hazards or OSHA rights and responsibilities, and information on additional compliance assistance resources.

Contact your local OSHA office for more information. OSHA’s On-site Consultation Program offers free and confidential advice for small and medium-sized businesses with fewer than 250 employees at a site (and no more than 500 employees nationwide) to help identify and correct hazards at worksites. On-site consultation services are separate from enforcement and do not result in penalties or citations. To locate the nearest OSHA Consultation office, visit: www.osha. gov/consultation or call 1-800-321-OSHA (6742).

Workers’ Rights

Workers have the right to:

- Working conditions that do not pose a risk of serious harm.

- Receive information and training (in a language and vocabulary the worker understands) about workplace hazards, methods to prevent them, and the OSHA standards that apply to their workplace.

- Review records of work-related injuries and illnesses.

- File a complaint asking OSHA to inspect their workplace if they believe there is a serious hazard or that their employer is not following OSHA’s rules. OSHA will keep all identities confidential.

- Exercise their rights under the law without retaliation, including reporting an injury or raising health and safety concerns with their employer or OSHA. If a worker has been retaliated against for using their rights, they must file a complaint with OSHA as soon as possible, but no later than 30 days.

For more information, see OSHA’s Workers page.

Contact OSHA

For questions or to get information or advice, to report an emergency, fatality, inpatient hospitalization, amputation, or loss of an eye, or to file a confidential complaint, or to request OSHA’s free on-site consultation service, contact your nearest OSHA office, visit www.osha.gov, or call OSHA at 1-800- 321-OSHA (6742), TTY 1-877-889-5627.

Many states operate their own occupational safety and health programs approved by OSHA. States enforce similar standards that may have different or additional requirements. A list of state plans is available at www.osha.gov/dcsp/osp.

Disclaimer

This Hazard Alert is not a standard or regulation, and it creates no new legal obligations. It contains recommendations as well as descriptions of mandatory safety and health standards [and other regulatory requirements]. The recommendations are advisory in nature, informational in content, and are intended to assist employers in providing a safe and healthful workplace. The Occupational Safety and Health Act requires employers to comply with safety and health standards and regulations promulgated by OSHA or by a state with an OSHA-approved state plan. In addition, the Act’s General Duty Clause, Section 5(a)(1), requires employers to provide their employees with a workplace free from recognized hazards likely to cause death or serious physical harm. The mention of any non-governmental organization or link to its website in this Hazard Alert does not constitute an endorsement by OSHA or NIOSH of that organization or its products, services, or website.