Summary Statement

A retrospective study of injuries from pneumatic nail guns in Washington State, including advice on engineering controls, administrative controls and PPE that can be used to reduce injuries.

Jan 20001

Numerous cases of nail gun injuries have been documented, involving injuries not only to the extremities (such as the hands) but also more-serious injuries to the brain, heart, neck and eyes. Systematic surveillance of work-related nail gun injuries has not been previously reported in the State of Washington or elsewhere. This study conducted retrospective surveillance of injuries related to the use of pneumatic nailers in Washington. Case data were extracted from the Washington State Workers’ Compensation database. Based on the findings, the authors outline engineering controls, administrative controls and personal protective equipment that can prevent injuries related to use of these devices.

Nail guns (nailers,

pneumatic hammers, pneumatic nailers or air-powered nailers) are relatively

new types of tools. With the squeeze of a trigger, they can drive anything

from a small finishing nail into a piece of plywood to a three-inch nail

into wood and concrete block. These tools, which look like large power

drills with a supply of nails and a pneumatic hose attached, can fire

up to nine nails per second (Gaylord 50) at velocities as high as 1,400

ft. per second (Hoffman, et al 1644). Thanks to such features, these tools

can substantially increase production rates in many jobs, which leads

to lower production and manufacturing costs.

However, nail guns impart a large amount of energy to a small projectile.

If the nail is not properly aimed, is shot before the operator is ready

or penetrates the work piece, then a high-velocity projectile is loose

in the workplace. If this nail strikes a worker, he may suffer an injury—ranging

from a slight scratch to a fractured bone or worse.

Case reports of nail gun injuries have been documented as early as 1966

(Montoli), and such injuries have been discussed in case series and instructional

publications. Reported injuries range from damage to the extremities to

more-serious injuries to the brain, heart, neck and eyes (Beaver and Cheatham;

Eachempati, et al; Bauch, et al; Vosswinkel and Bilfinger; Hoffman, et

al; Alberico, et al; Lee and Sternberg). However, no systematic surveillance

of these injuries has been reported— in the state of Washington or elsewhere.

The objective of this study was to conduct retrospective surveillance

of work-related injuries related to the use of pneumatic nailers in Washington.

RESEARCH

METHODS

In Washington, employers

must obtain WC insurance through the Dept. of Labor and Industries (L&I),

unless they are able to self-insure. Hence, two-thirds of workers in the

state are covered by the State Fund insurance. The remaining one-third

typically work for the largest 400 companies and are covered through their

employers. In addition, self-employed workers are not required to have

coverage.

The L&I Industrial

Insurance System (LINIIS) contains data needed to administer claims, including

incident type, nature of injury, source of injury, occupation, employer

information, claim status and cost. Details are encoded using codes in

ANSI Z16.2, “Methods of Recording Basic Facts Relating to the Nature

and Occurrence of Work Injuries”; these codes indicate injury type

and source as well as the nature of the injury and body part involved

in the case.

An employer’s

industry is identified using standard industrial classification (SIC)

codes and a worker’s occupation is identified by standard census

occupation codes. The state also uses a risk classification, known as

the Washington Industrial Classification (WIC), to describe a job. This

system uses a combination of industry and occupation to group workers

by similar risk of injury for insurance purposes.

Data extracted for

this study were assembled by matching records with a specific source of

injury to textual data collected on the claim initiation form. Textual

responses were then searched for terms indicative of nail gun injuries.

To be included in the study, a claim must have met each of the following

criteria.

1) Incident occurred

between Jan. 1, 1990, and Dec. 31, 1998.

2) Source of injury

category used was either a hammer-type power hand tool (which includes

hammers, tampers, jackhammers and air nailers) or an unusual metal item

(including fasteners such as bolts, nails, nuts, pins, rivets, screws,

spikes, staples, clamps and couplings). Non-nail gun-related incidents

were excluded when criterion number 4 was applied to the data.

3) In addition to

the primary source, the associated source of injury also had to be listed

as either a hammer-type power hand tool or as an unusual metal item.

4) A nail gun was

specifically identified in the incident report. A nail gun was assumed

to be involved if the report contained any of the following words: “nail-gun,”

“nail gun,” “nailer”; or both of the following words:

“pneumatic” and “nail.”

5) Claims were limited

to those under State Fund insurance jurisdiction.

6) Claims were limited

to accepted claims, including “compensable,” “non-compensable,”

“fatal,” “kept on salary,” “loss of earning power”

and “total permanent disability” claims.

TABLE 1 Cost & Number of Lost-Time Days [1990-1998]

|

WIC

Description [Code]

|

Cost

|

#

Lost-Time Days

|

Percentage

|

|

Wood

Frame Building Construction (0150)

|

$3,853,378

|

26,270

|

61.3

|

|

Interior

Finish Carpentry (0513)

|

$388,889

|

1,571

|

3.7

|

|

Building

Construction NOC (0518)

|

$298,065

|

1,647

|

3.8

|

|

Carpentry

NOC (0516)

|

$274,941

|

2,611

|

6.1

|

|

Wood

Products Manufacturing (2903)

|

$251,255

|

3,467

|

8.1

|

|

Wallboard

Installation (0515)

|

$199,083

|

713

|

1.7

|

|

Roofing

(0507)

|

$171,728

|

1,512

|

3.5

|

|

Cabinet/Countertop

Manufacturing (2907)

|

$149,668

|

1,928

|

4.5

|

|

Other

|

$645,385

|

3,122

|

7.3

|

|

Total

|

$6,232,392

|

42,841

|

NOC = Not otherwise classified

Table 2 Indicated Body Part for Nail Gun Injuries [1990-1998]

| Claimants in WIC 0510 accounted for more than 60 percent of recorded lost-time days. The most common body part injured was the finger(s) (42.7 percent) and hand (23.3 percent). The foot, thigh, wrist, knee and toe(s) were other commonly identified sites of injury. In 1.4 percent of the injuries, the eye was identified as the injured body part. Nearly all claims involved the claimant being "struck by" an "unusual object," "flying object" or "object not elsewhere classified." |

Body

Part

|

Frequency

|

Percentage

|

Cumulative

Percentage

|

| Finger(s) |

1,543

|

42.7

|

42.7

|

|

| Hand |

844

|

23.3

|

66.0

|

|

| Foot |

215

|

5.9

|

72.0

|

|

| Thigh |

167

|

4.6

|

76.6

|

|

| Wrist |

139

|

3.8

|

80.4

|

|

| Knee |

137

|

3.8

|

84.2

|

|

| Toe(s) |

104

|

2.9

|

87.1

|

|

| Lower Leg |

66

|

1.8

|

88.9

|

|

| Forearm |

64

|

1.8

|

90.7

|

|

| Eye(s) |

49

|

1.4

|

92.0

|

|

| Leg(s) Unusual |

48

|

1.3

|

93.4

|

|

| Other |

240

|

6.6

|

100.0

|

|

| Total | 3,616 |

DATA

ANALYSIS

Frequency of claims by year of injury, industry, occupation, risk class (WIC), type and nature of injury, and body part involved were used to describe general characteristics of the reported injuries. Claims rates were determined by dividing the number of identified claims by the number of hours worked. The number of hours worked was extracted from payroll data reported to L&I. This was then converted to “full time equivalent workers” (FTEs) by multiplying the claims rate by a conversion factor which assumes that the average FTE works 2,000 hours per year. Claims rates were reported in unit of claims per 10,000 FTEs/year by multiplying the rate by 10,000.

To identify industry and occupation groups for intervention priority, the prevention index (PI) was calculated. PI is the average of the frequency ranking and claims rate ranking by industry or WIC. Claims rates for categories containing less than 16 cases or 90,000 hours (the equivalent of five FTEs per year) were not included. Trends over time in claims rates were then assessed using Poisson regression and assumed linear trend. Invalid industry codes were not used in this analysis.

RESULTS

In the nine-year period 1990 through 1998, 3,616 accepted State Fund claims were associated with nail gun injuries. Of those, most were non-compensable medical-only claims (2,885), with approximately one-fifth being compensable, involving more than three days away from work. No fatalities involving nail guns were reported during this period.

For the nine years,

the total cost was $6,232,392 or $692,548 per year. More than 60 percent

of this cost was incurred from claimants in the wood frame building construction

class (WIC 0510) (Table 1). The median number of lost-time

days was zero for all claimants. Of those with compensable claims, the

median number of lost-time days was 11. Claimants in WIC 0510 also accounted

for more than 60 percent of recorded lost-time days (Table

1).

The average age of

claimants was 29.6 years. About two-thirds were single and almost all

were male. In comparison, the average age of claimants not reporting nail

gun injuries was 34.6 years; nearly 70 percent were male and 60 percent

were single.

The most-common body part injured was the finger(s) (42.7 percent) and hand (23.3 percent). The foot, thigh, wrist, knee and toe(s) were other commonly identified sites of injury (Table 2). In 1.4 percent of the injuries, the eye was identified as the injured body part. Nearly all claims (93 percent) involved the claimant being "struck by" an "unusual object," "flying object" or "object not elsewhere classified." Another two percent involved the claimant being "struck by falling object." Eighty-five percent of the injuries resulted in a "cut," while eight percent caused a fracture.

The most-common occupation reported by claimants was carpentry (54.3 percent). Other occupations included construction laborers (9.9 percent), non-construction laborers (5.6 percent), construction supervisors (3.3 percent), assemblers (2.7 percent), roofers (2.3 percent), cabinet makers and bench carpenters (1.6 percent), construction trades not elsewhere classified (1.5 percent) and construction helpers (1.1 percent). Nearly eight percent did not report any occupation. Occupations linked with construction accounted for more than 70 percent of the claims.

Of the WICs, building construction was the most-commonly reported among claimants; it included the following categories: wood frame building, construction or alterations (55.4 percent); interior finish carpentry (5.1 percent); building alteration and concrete construction not otherwise classified (4.9 percent); building repair and carpentry (3.8 percent); and roofing construction and repair (2.4 percent). Manufacture of wood products was also commonly reported; this class includes the manufacture of wood boxes, shocks, pallets or bins (2.8 percent); cabinets, countertops or fixtures (2.8 percent); wood trusses (2.1 percent); factory-built homes (1.7 percent); and wood doors, sashes, molding and miscellaneous millwork (1.1 percent) (Table 3).

TABLE 3 WC Claims Rates for Nail Gun Injuries by WIC [1990-1998]

| WIC | Description | Frequency | Employee Hours [Ten Thousands] | Rate [/10,00 FTEs-Yr.] | PI | Slope of Rate Over Time | Of the WICs, building construction was the most-commonly reported among claimants. For industry classifications as defined by SIC codes, general contractors for single-family homes and carpentry work were the most-reported classifications among claims—42.5 percent and 12.4 percent, respectively. |

| 0510 | Wood Frame Building Construction |

2,002

|

19,452

|

205.8

|

1

|

0.0645 |

|

| 0513 | Interior Finish Carpentry |

186

|

5,671

|

65.6

|

4

|

0.0412

|

|

| 0516 | Carpentry NOC |

138

|

3,084

|

89.5

|

4.5

|

0.0407

|

|

| 2903 | Wood Products Manufacturing |

246

|

11,464

|

42.9

|

4.5

|

0.0414

|

|

| 2908 | Factory Built Housing |

75

|

974

|

154.1

|

5

|

0.0267

|

|

| 0105 | Fence Erection |

48

|

732

|

131.2

|

6

|

-0.0501

|

|

| 0518 | Building Construction NOC |

178

|

8,791

|

40.5

|

6

|

-0.0208

|

|

| 0507 | Roofing |

88

|

3,076

|

57.2

|

6.5

|

0.1376**

|

|

| 2907 | Cabinet/Countertop Manufacturing |

103

|

5,949

|

34.6

|

7.5

|

-0.0768*

|

|

| 7114 | Temporary Help -Assembly |

35

|

2,055

|

34.1

|

10.5

|

-0.0152

|

|

| 3404 | Aluminum Product Manufacturing |

38

|

13,977

|

5.4

|

11.5

|

-0.0548

|

|

| 1108 | Glass Merchants |

18

|

2,310

|

15.6

|

12.5

|

0.0003

|

|

| 6709 | Sheltered Workshops |

19

|

5,352

|

7.1

|

12.5

|

-0.0710

|

|

| 2009 | Building and Home Improvement Centers |

23

|

9,444

|

4.9

|

13

|

-0.3062

|

|

| 3510 | Plastic Products Manufacturing |

16

|

9,527

|

3.4

|

15.75

|

-0.0423

|

|

| 3402 | Machine Shops |

17

|

21,976

|

1.5

|

16

|

0.0728

|

|

| 2104 | Fruit and Vegetable Packing |

16

|

17,228

|

1.9

|

16.25

|

0.0097

|

* = P < 0.05

** = P < 0.01

ˆ = Estimates based on data from 1993-1998

NOC = not otherwise classified

TABLE 4 WC Claims Rates of Nail Gun Injuries by SIC [1990-1998]

|

SIC

|

Description

|

Frequency

|

Employee

Hours [Ten Thousands]

|

Rate

[/10,000 FTEs-YR]

|

PI

|

| 15 | Building Construction -General Contractors & Operative | 1,818 | 46,670 | 77.9 | 1 |

| 24 | Lumber & Wood Products, Except Furniture | 306 | 32,432 | 18.9 | 2.5 |

| 17 | Construction Special Trade Contractors | 805 | 108,816 | 14.8 | 2.5 |

| 52 | Building Materials, Hardware, Garden Supply & Mobile Home | 91 | 27,169 | 6.7 | 4.5 |

| 34 | Fabricated Metal Products, Except Machinery & Transportation | 33 | 19,593 | 3.4 | 7.5 |

| 25 | Furniture & Fixtures | 17 | 4,730 | 7.2 | 8.5 |

| 65 | Real Estate | 46 | 62,661 | 1.5 | 8.5 |

| 73 | Business Services | 76 | 112,861 | 1.3 | 9 |

| 47 | Transportation Services | 21 | 14,641 | 2.9 | 9.5 |

| 57 | Home Furniture, Furnishings and Equipment Stores | 23 | 27,354 | 1.7 | 10 |

| 32 | Stone, Clay, Glass and Concrete Products | 16 | 8,953 | 3.6 | 10.25 |

| 16 | Heavy Construction Other than Building Construction | 18 | 21,074 | 1.7 | 10.5 |

| 50 | Wholesale Trade - Durable Goods | 42 | 99,769 | 0.8 | 11 |

| 83 | Social Services | 25 | 50,527 | 1.0 | 11.5 |

| 35 | Industrial and Commercial Machinery, and Computer Equipment | 16 | 23,680 | 1.4 | 13.25 |

For industry classifications as defined by SIC codes, general contractors for single- family homes and carpentry work were the most-reported classifications among claims—42.5 percent and 12.4 percent, respectively. In addition, other construction- related industries, such as contractors for nonresidential buildings other than industrial buildings; roofing, siding and sheet metal work; and special trade contractors not elsewhere classified, were among the highest-ranked for the number of nail-gun-associated injuries.

Aside from construction, the following industries were among those with a high number of claims: manufacturing of wood pallets/skids, manufacturing of cabinets, manufacture of structural wood members not elsewhere classified, manufacture of prefabricated wood buildings and components, and retail trade of lumber and other building (Table 4).

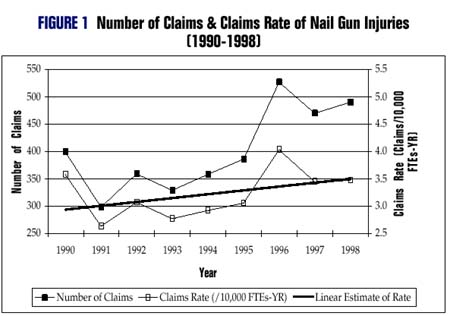

The average nail-gun-related

claims rate for the nine years was 3.2 claims/10,000 FTEs (Table

5). This rate sharply declined between 1990 and 1991. From 1991 to

1996, the rate increased, peaking in 1996. It then decreased slightly,

but rates in 1997 and 1998 were greater than reported rates before 1996.

As Figure 1 shows, since 1991, the increasing trend in the claims rate

was statistically significant (p=0.0061). Tables 3 and

4 list the claims rates and PI for the top WIC (four

digit) and two-digit SIC. Using SIC codes, general contractors for single-family

homes had the highest PI (1.0). Using WIC, wood frame building construction

or alterations had the highest PI (1.0).

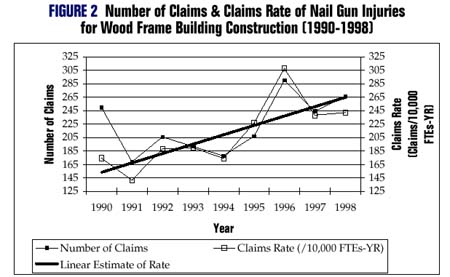

Claims rates were

examined for trends over the nine-year study period for each WIC category.

This analysis found that not all categories demonstrated an increasing

trend of nail gun claims over the study period. Table 3

lists slope parameters for the Poisson regressions for each category.

Only wood frame building construction (0510) and roofing (0507) showed

statistically significant increasing trends over time (Figure

2). After continual increases of claims rates, factory-built housing

(2908) showed a sharp decline in rate and number of claims during 1998.

A statistically significant

decrease in claims rate was also noted in the manufacture, modification

or repair of cabinet, countertop and fixture category (2907), as was a

statistically significant decrease (p=0.028) in the building and home

improvement centers category (2009). Estimates of slope for these establishments

were based on the last six years. By excluding 1990, a statistically significant

increase (p=0.0185) in the claims rate was noted for fruit and vegetable

packing

(2104) as well.

To further investigate the increase of claims in wood frame building construction, the proportion of all construction claims attributed to nail gun injuries was determined. In 1991, 6,662 claims were accepted by the State Fund from claimants in this industry class. Of these, 2.5 percent were identified as nail gun injuries. By 1998, only 4,665 claims were accepted for this group, but the percentage of injuries identified as being nail-gun- related more than doubled to 5.7 percent; risk ratio=2.25, 95 percent CI: 1.86, 2.72.

TABLE 5 WC Claims Rate By Year [1990-1998]

|

Year

|

Frequency

|

Employee

Hours

[Ten Thousands] |

Rate

[/10,000 FTEs-Yr.] |

|

1990

|

399

|

223,185

|

3.6

|

|

1991

|

298

|

226,265

|

2.6

|

|

1992

|

359

|

233,865

|

3.1

|

|

1993

|

329

|

237,383

|

2.8

|

|

1994

|

358

|

245,029

|

2.9

|

|

1995

|

386

|

252,013

|

3.1

|

|

1996

|

527

|

260,495

|

4.0

|

|

1997

|

470

|

272,161

|

3.5

|

|

1998

|

490

|

282,408

|

3.5

|

|

Total

|

3,616

|

2,234,734

|

3.2

|

|

The

average nail-gun-related claims rate for the nine years was 3.2

claims/10,000 FTEs. This rate sharply declined between 1990 and

1991. From 1991 to 1996, the rate increased, peaking in 1996. It

then decreased slightly, but rates in 1997 and 1998 were greater

than reported rates before 1996.

|

|||

DISCUSSION

From 1990 through

1998, 3,616 injuries involving nail guns incurred WC costs of $6,232,392.

The most-common injury was a cut, usually resulting from a claimant being

struck by a flying or unusual object. Injuries in the wood frame building

construction or alterations category accounted for more than half of the

claims, some 60 percent of incurred costs and the highest claims rate.

In addition, this industry class had the highest PI and its claims rate

has been increasing since 1990. Other construction categories, as well

as the manufacture or assembly of wood products, have also contributed

to the increased number of nail gun injuries.

This surveillance

report is the first to describe the increase of work-related nail gun

injuries over this nine-year period. While the report documents the increase

of injuries, data are not sufficient to determine whether this is related

to an increase in the number of nail guns in use; an increase in the number

of hours the tool is used; a decrease in tool proficiency; a decline in

jobsite safety; or some combination of these factors.

Other study limitations

must also be noted. This report relies on the accuracy and completeness

of WC data reported to L&I. The case definition for a nail gun injury

is sensitive to the coding of WC claims. It may be fair to suggest that

the number of nail gun incidents has been underestimated for the following

reasons.

1) At least some injuries may be treated at the worksite and are not reported to the WC system.

2) The definition

of a nail gun incident may not be sensitive to all nail-gun related injuries.

Certain incidents may not have been identified due to misspellings, coding

inconsistencies or lack of keyword in the textual report. Such problems

would lead to an underestimation of the number of identified incidents.

3) The number of

hours reported by the company was used as a surrogate for the number of

hours a worker was exposed to potential incidents. One would expect that

most workers are not exposed to potential incidents throughout the entire

workday. Hence, it is likely the number of hours worked does not reflect

the number of hours exposed. As a result, stated claims rates are an underestimation

of actual rates.

4) The proportion

of hours workers are exposed to potential nail gun incidents likely varies

between industrial classifications. Therefore, the level of underestimation

of claims rates, which depends on the proportion of hours actually exposed,

may vary between industrial classifications.

Claims with an invalid SIC code were not included in analysis involving this variable. However, 1.6 percent of all nail gun injuries were reported among claims in this category. Further analysis demonstrated that of claims with an invalid SIC code, nearly 70 percent were categorized in the wood frame building construction or alterations WIC. Therefore, claims with an invalid SIC do not likely represent an industry not already reported as one with a high number of nail gun injuries.

PREVENTING

INJURIES

Since these tools

will likely continue to be used, management can reduce worker exposure

by using a combination of engineering controls, administrative controls

and personal protective equipment (PPE). These are the basic control strategies

considered when attempting to reduce workplace injuries or illnesses.

The priority for implementation starts with engineering controls, followed by administrative controls, then PPE. This hierarchy reflects the fact that it is better to first attempt to control an exposure using a method which requires no human intervention—where the hazard can be engineered out. Likewise, it is generally better to have en employee prevent an incident than it is to have him/her rely on PPE to prevent the exposure that will cause injury.

Because of the mobile nature of these tools, a combination of controls may be necessary. The following recommendations, based on various sources, are designed to reduce the number and severity of nail-gun-related injuries (Oregon Dept. of Consumer and Business Services; SENCO Tools; Canadian Center for Occupational Health and Safety; Eagle Insurance Group; Makita USA Inc.).

Data for Figure 2

| Year | Claims | Claims Rate |

|

1990

|

250

|

175

|

|

1991

|

169

|

142

|

|

1992

|

206

|

188

|

|

1993

|

192

|

190

|

|

1994

|

178

|

174

|

|

1995

|

207

|

226

|

|

1996

|

290

|

308

|

|

1997

|

244

|

238

|

|

1998

|

266

|

242

|

Nail guns can substantially increase production rates in many jobs, which leads to lower production and manufacturing costs. However, they also introduce many hazards that must be controlled to prevent injury.

Engineering

Controls

- Use the sequential trigger (also known as a restrictive trigger or operating in the trigger fire mode). This mechanism allows a nail to be fired only if the trigger has been depressed after the nose guard trigger release has been activated; in addition, it permits only one nail to be fired per trigger activation. As employees gain experience with the tool, the “bump” trigger system can be implemented to reduce the potential risk of musculoskeletal disorders (e.g., trigger finger).

- Manufacturers should work with users and safety professionals to better balance the speed and productivity of using the “bump” mode with the accuracy and potential for fewer acute trauma injuries using the sequential mode. In all cases, the possibility of trigger finger must be considered.

- The male end (nipple) of the compression fitting should be the fitting screwed into the tool, and the loose end attached to the air hose should be the female fitting. If reversed, air pressure may remain in the tool after the air hose has been removed, which could allow a nail to be fired even if the hose is not attached.

- Use only clean, dry compressed air at manufacturer-recommended pressure.

- Never use bottled gases or air.

- Secure the hose when working on scaffolding.

Administrative

Controls Training

- Have all users review the owner’s manual for operation, maintenance and safety procedures. This could be a good annual safety meeting topic or monthly safety tailgate meeting exercise.

- Have workers demonstrate safe use of the tool. This is crucial for employees with little or no experience with pneumatic nailers.

- When purchasing or renting a tool, ensure that the distributor reviews the basics of safe tool use.

Use

& Transportation

- Post warnings about the use of high-power pneumatic tools.

- Do not carry the tool by the hose or with a finger on the trigger.

- Do not hold down the trigger unless intending to fire the tool—especially when walking or climbing a ladder.

- Never point the tool at anyone even if it is empty or disconnected from the air supply.

- Whenever the tool is initially connected to the air supply, aim the tool away from the body and other people. It is possible for the trigger mechanism to stick in the activated position; when this occurs, the gun will fire a nail even though the user has not touched the trigger.

- Never assume the tool is empty.

- Do not fire the tool unless the nose is placed firmly against the work piece.

- Keep the free hand out of the line of fire.

- Never rest the tool against any part of the body.

- Ensure that the tool is appropriate for the job.

- Design the task so that coworkers will be out of the line of fire.

- Disconnect the air hose prior to clearing a jam, repairing the unit, handing it to another worker, leaving the work area or moving the tool to another work area.

- Since sparks can

fly from the tool when it is in use, do not operate it near flammable

materials such as gasoline, thinner, paint or adhesives. Those materials

may ignite and explode, causing serious injury.

Checks

& Maintenance

- Inspect and perform any necessary maintenance on the tool and compressor prior to use.

- Check the air supply and pressure prior to connecting the tool.

- Make sure the nose guard safety spring is operational prior to use.

- Before clearing a blockage, disconnect the hose, then depress the trigger to ensure that all air is exhausted from the tool.

Safe

Construction Methods

- Nail from top to bottom when nailing wall sheathing in a vertical position.

- Nail from the eaves to the ridge when working on a roof.

- Move forward when nailing horizontal areas.

- Nails may not always be driven in straight or can be deflected, so keep hands and fingers away from areas where errant nails may exit the work piece.

Personal

Protective Equipment

- Always wear safety glasses.

- Use hearing protection as necessary according to the job environment.

- Wear steel-toe boots as the work environment dictates.

Management can reduce worker exposure to nail-gun hazards by using a combination of engineering controls, administrative controls and personal protective equipment.

REFERENCES

Alberico, G., et al. "An Unusual Case of Nail Gun Injury: Penetrating Neck Wound with Nail Retention in the Right Pleural Cavity." Journal of Trauma. 43(1997): 153-156.

American National

Standards Institute (ANSI). “Methods of Recording Basic Facts Relating

to the Nature and Occurrence of Work Injuries.” New York: American

National Standards Institute, 1969.

Bauch, C.D., et

al. “Penetrating Injury to the Brainstem After a Nailgun Accident:

A Case Study.” American Journal of Audiology. 8(1999): 57-64.

Beaver, A.C. and

M.L. Cheatham. “Life-Threatening Nail Gun Injuries.” American

Surgeon. 65(1999): 1113-1116.

Canadian Center

for Occupational Health and Safety. “Powered Hand Tools: Basic

Safety for Pneumatic Tools.” Nov. 3, 1999. http://www.ccohs.ca/oshanswers/safety_haz/power_tools/pneumat.html.

Canadian Center

for Occupational Health & Safety. “Powered Hand Tools: Basic

Safety for Pneumatic Tools.” Nov.,1999.

http://www.ccohs.ca/oshanswers/safety_haz/Power_tools/nailing.html.

Eachempati, S.R.,

et al. “The Image of Trauma: Nail Gun Injury to the Right Ear and

Base of Skull.” Journal of Trauma. 47(1999): 985.

Eagle Insurance Group. “Construction Safety: Nail Gun Safety.”

SMO 95-0106. Seattle: Eagle Insurance, 1995.

* http://www.eig.com/smos/smo95016.html.

Gaylord, W.A. “Nail

Guns: Speed Before Safety.” Trial. 30(1994): 46-48, 50,

52.

Hoffman, D.R., et al. “Nail Gun Injuries of the Hand.” American

Family Physician. 56(1997): 1643-1646.

Lee, B.L. and P.

Sternberg Jr. “Ocular Nail Gun Injuries.” Ophthalmology.

103(1996): 1453-1457.

Makita USA Inc.

Pneumatic Framing Nailer Instruction Manual. Model AN922/942.

La Miranda, CA: Makita, 1999.

Montoli, E. “Accidents

Due to the Nail Driving Gun: Personal Cases.” Minerva Med.

57(1966): 174-182.

Office of Management and Budget (OMB). Standard Industrial Classification Manual. Washington, DC: OMB, 1987.

Oregon Dept. of

Consumer and Business Services. “Use of Pneumatic Nail Guns.”

Hazard Alert. Salem, OR: Oregon Dept. of Occupational Safety and Health.

SENCO Tools. “SENCO

Tools Safety Tips.” Sept. 3, 1999.

http://www.senco.com/.

* eLCOSH editors' note: This link was not working as of July 2001.

____________________________

James Baggs,

Ph.D., is an epidemiologist with the Safety & Health

Assessment & Research for Prevention (SHARP) program in the State

of Washington’s Dept. of Labor and Industries. He holds a B.S.

in Biology from the University of Nevada, Las Vegas, and a Ph.D. from

the Rollins School of Public Health at Emory University. Prior to joining

the SHARP program, Baggs worked with the Centers for Disease Control

and Prevention, focusing on epidemiology and surveillance of HIV genetic

variation globally. His major areas of research include surveillance

of occupational injuries and illness, occupational asthma, hospitalized

burns due to occupational exposures and surveillance methodology.

Marty Cohen,

Sc.D., CIH, is an industrial hygienist with SHARP. In addition,

he is program manager for the NIOSH-funded Fatality Assessment and Control

Evaluation (FACE) Program in Washington and an affiliate assistant professor

at the University of Washington. Cohen holds an Sc.D. in Environmental

Health/Exposure Assessment from the Harvard School of Public Health.

John Kalat

is a computer information system specialist who reports to SHARP

from the Information Services Applications & Data Management Group.

He holds a B.A. from Evergreen State College.

Barbara Silverstein, Ph.D., M.P.H., is SHARP’s research director. She holds an M.S. in Nursing from the University of California, San Francisco; and an M.P.H. in Epidemiology and Environmental and Industrial Health, and Ph.D. in Epidemiologic Science, both from the University of Michigan.

ACKNOWLEDGMENT

The authors wish to thank Mark Kastenbaum, Tom Sjostrom, Heather Grob and George King for their insightful review and recommendations for this report. We also thank representatives from business and labor for input from a user’s perspective, as well as Dr. Eric Smith for his insight into worker health and safety issues.