Summary Statement

http://www.cpwrconstructionsolutions.org/structural_steel/hazard/1175/weld-plasma-cut-air-arc-and-flame-cut-metal-eye-injury.html

summer 2001

Portland cement is

one of the most widely used materials in construction. Applications include

concrete floors, walls, and pavement; concrete blocks; and different mixtures

of mortar and grout.

Thousands of construction workers are exposed to concrete every day without harm. But anyone who uses or supervises the use of portland cement should know its health hazards and the safe working procedures necessary to minimize exposure. This article outlines those hazards and makes recommendations on how to use cement safely.

Waterproof rubber boots are essential in working with wet concrete

Health effects

Cement can cause ill health by skin contact, eye contact, or inhalation. Risk of injury depends on duration and level of exposure and individual sensitivity.

Hazardous materials in wet concrete and mortar include:

- alkaline compounds

such as lime (calcium oxide) that are corrosive to human tissue

- trace amounts

of crystalline silica which is abrasive to the skin and can damage lungs

- trace amounts of chromium that can cause allergic reactions.

The hazards of wet cement are due to its caustic, abrasive, and drying properties.

Wet concrete contacting the skin for a short period and then thoroughly washed off causes little irritation. But continuous contact between skin and wet concrete allows alkaline compounds to penetrate and burn the skin.

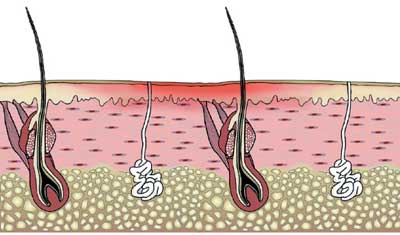

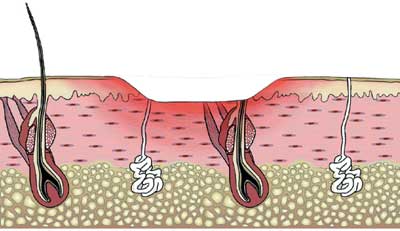

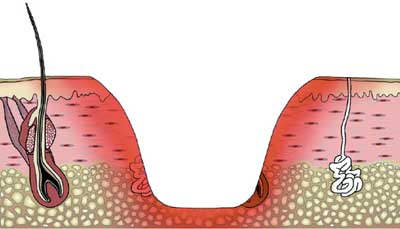

When wet concrete or mortar is trapped against the skin—for instance, by falling inside a worker’s boots or gloves or by soaking through protective clothing—the result may be first, second, or third degree burns or skin ulcers. These injuries can take several months to heal and may involve hospitalization and skin grafts.

First

degree burn - outer

skin layer

Second degree burn - middle skin layer

Third degree burn - deep skin layer

Ironically, severe cases often occur when personal protective clothing or equipment is worn. Wet concrete may get trapped inside rubber boots or gloves or gradually soak through coveralls. Concrete finishers kneeling on fresh concrete have had their knees severely burned. Corrosive bleed water from the concrete is absorbed by the worker’s pants and held against the skin for prolonged periods.

Without waterproof knee pads, kneeling on wet concrete can irritate

or burn the skin

Cement dust released during bag dumping or concrete cutting can also irritate the skin. Moisture from sweat or wet clothing reacts with the cement dust to form a caustic solution.

Allergic skin reactionSome workers become allergic to the hexavalent chromium in cement. A small yet significant percentage of all workers using cement will develop an allergy to chromium, with symptoms ranging from a mild rash to severe skin ulcers.

In addition to skin reactions, hexavalent chromium can cause a respiratory allergy called occupational asthma. Symptoms include wheezing and difficulty breathing. Workers may develop both skin and respiratory allergies to hexavalent chromium.

It’s possible to work with cement for years without any allergic skin reaction and then to suddenly develop such a reaction. The condition gets worse until exposure to even minute quantities triggers a severe reaction. The allergy usually lasts a lifetime and prevents any future work with wet concrete or powder cement.

Eye contactExposure to airborne dust may cause immediate or delayed irritation of the eyes. Depending on the level of exposure, effects may range from redness to chemical burns and blindness.

InhalationInhaling high levels of dust may occur when workers empty bags of cement. In the short term, such exposure irritates the nose and throat and causes choking and difficult breathing. Sanding, grinding, or cutting concrete can also release large amounts of dust containing high levels of crystalline silica. Prolonged or repeated exposure can lead to a disabling and often fatal lung disease called silicosis. Some studies also indicate a link between crystalline silica exposure and lung cancer.

Dry cutting

generates high levels of dust

The following are some basic recommendations for handling and using cement safely.

Personal protectionTo protect skin from cement and cement mixtures, workers should wear:

- alkali-resistant gloves

- coveralls with long sleeves and full-length trousers (pull sleeves down over gloves and tuck pants inside boots and duct-tape at the top to keep mortar and concrete out)

- waterproof boots high enough to prevent concrete from flowing in when workers must stand in fresh concrete

- suitable respiratory protective equipment such as a P, N or R 95 respirator when cement dust can’t be avoided

- suitable eye protection where mixing, pouring, or other activities may endanger eyes (minimum—safety glasses with sideshields or goggles, under extremely dusty conditions, tight-fitting unvented or indirectly vented goggles. Don’t wear contact lenses when handling cement or cement products).

- When laying concrete block, have different sizes on hand to avoid cutting or hammering to make them fit.

- Work in ways that minimize the amount of cement dust released.

- Where possible, wet-cut rather than dry-cut masonry products.

- Mix dry cement in well-ventilated areas.

- Make sure to work upwind from dust sources.

- Where possible, use ready-mixed concrete instead of mixing on site.

- When kneeling on fresh concrete, use a dry board or waterproof kneepads to protect knees from water that can soak through fabric.

- Remove jewelry such as rings and watches because wet cement can collect under them.

- Clothing contaminated

by wet cement should be quickly removed. Skin in contact with wet cement

should be washed immediately with

large amounts of cool clean water. - Don’t wash your hands with water from buckets used for cleaning tools.

- Provide adequate hygiene facilities on site for workers to wash hands and face at the end of a job and before eating, drinking, smoking, or using the toilet. Facilities for cleaning boots and changing clothes should also be available.

Under the Workplace Hazardous Materials Information System (WHMIS) in force across Canada, workers handling, using, or exposed to dry or wet cement must be educated in hazards and controls.

First aidSkin contaminated with wet or dry cement should be washed with cold running water as soon as possible. Open sores or cuts should be thoroughly flushed and covered with suitable dressings. Get medical attention if discomfort persists. Contaminated eyes should be washed with cold tap water for at least 15 minutes before the affected person is taken to hospital.

ReferencesHealth and Safety

Executive, Cement, Construction Information Sheet No 26

(revised)

Portland Cement Association, Skin Safety with Cement and Concrete,

videotape