Summary Statement

Student manual on electrical safety with information on recognizing, evaluating and avoiding hazards related to electricity.

January 2002

Safety Model Stage 1— Recognizing Hazards

How Do You Recognize Hazards?

The first step toward protecting yourself is recognizing the many hazards you face on the job. To do this, you must know which situations can place you in danger. Knowing where to look helps you to recognize hazards.

-

Inadequate wiring is dangerous.

-

Exposed electrical parts are dangerous.

-

Overhead powerlines are dangerous.

-

Wires with bad insulation can give you a shock.

-

Electrical systems and tools that are not grounded or double-insulated are dangerous.

-

Overloaded circuits are dangerous.

-

Damaged power tools and equipment are electrical hazards.

-

Using the wrong PPE is dangerous.

-

Using the wrong tool is dangerous.

-

Some on-site chemicals are harmful.

-

Defective ladders and scaffolding are dangerous.

-

Ladders that conduct electricity are dangerous.

-

Electrical hazards can be made worse if the worker, location, or equipment is wet.

|

|

|

| Worker was electrocuted while removing energized fish tape. |

| An

electrician was removing a metal fish tape from a hole at the

base of a metal light pole. (A fish tape is used to pull wire

through a conduit run.) The fish tape became energized, electro-cuting

him. As a result of its inspection, OSHA issued a citation for

three serious violations of the agency's construction standards.

If the following OSHA requirements had been followed, this death could have been prevented.

|

Fish Tape. |

Inadequate wiring hazards

An electrical hazard exists when the wire is too small a gauge for the current it will carry. Normally, the circuit breaker in a circuit is matched to the wire size. However, in older wiring,

|

| This

hand-held sander has exposed wires and should not be used. |

When you use an extension cord, the size of the wire you are placing into the circuit may be too small for the equipment. The circuit breaker could be the right size for the circuit but not right for the smaller-gauge extension cord. A tool plugged into the extension cord may use more current than the cord can handle without tripping the circuit breaker. The wire will overheat and could cause a fire.

The kind of metal used as a conductor can cause an electrical hazard. Special care needs to be taken with aluminum wire. Since it is more brittle than copper, aluminum wire can crack and break more easily. Connections with aluminum wire can become loose and oxidize if not made properly, creating heat or arcing. You need to recognize that inadequate wiring is a hazard.

|

|

|

|

|

|

|

|

|

|

Exposed electrical parts hazards

Electrical hazards exist when wires or other electrical parts are exposed. Wires and parts can be exposed if a cover is removed from a wiring or breaker box. The overhead wires coming into a home may be exposed. Electrical terminals in motors, appliances, and electronic equipment may be exposed. Older equipment may have exposed electrical parts. If you contact exposed live electrical parts, you will be shocked. You need to recognize that an exposed electrical component is a hazard.

Overhead powerline hazards

Most people do not realize that overhead powerlines are usually not insulated. More than half of all electrocutions are caused by direct worker contact with energized powerlines. Powerline workers must be especially aware of the dangers of overhead lines. In the past, 80% of all lineman deaths were caused by contacting a live wire with a bare hand. Due to such incidents, all linemen now wear special rubber gloves that protect them up to 34,500 volts. Today, most

electrocutions involving overhead powerlines are caused by failure to maintain proper work distances.

|

Overhead powerlines kill many workers! |

|

|

|

|

| Watch out for exposed electrical wires around electronic equipment. | Electrical line workers need special training and equipment to work safely. |

|

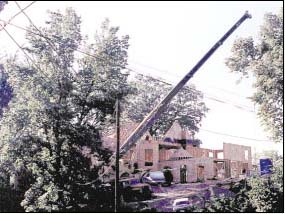

Shocks

and electrocutions occur where physical barriers are not in place

to prevent contact with the wires. When dump trucks, cranes, work

platforms, or other conductive materials (such as pipes and ladders) contact overhead wires, the equipment operator or other workers can be killed. If you do not maintain required clearance distances from powerlines, you can be shocked and killed. (The minimum distance for voltages up to 50kV is 10 feet. For voltages over 50kV, the minimum distance is 10 feet plus 4 inches for every 10 kV over 50kV.) Never store materials and equipment under or near over-head powerlines. You need to recognize that overhead powerlines are a hazard. |

| Operating

a crane near overhead wires is very hazardous. |

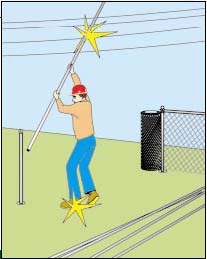

Five

workers were constructing a chain-link fence in front of a house,

directly below a 7,200-volt energized powerline. As they prepared

to install 21-foot sections of metal top rail on the fence, one

of the workers picked up a section of rail and held it up vertically.

The rail contacted the 7,200-volt line, and the worker was electrocuted.

Following inspection, OSHA determined that the employee who was

killed had never received any safety training from his employer

and no specific instruction on how to avoid the hazards associated

with overhead powerlines. Five

workers were constructing a chain-link fence in front of a house,

directly below a 7,200-volt energized powerline. As they prepared

to install 21-foot sections of metal top rail on the fence, one

of the workers picked up a section of rail and held it up vertically.

The rail contacted the 7,200-volt line, and the worker was electrocuted.

Following inspection, OSHA determined that the employee who was

killed had never received any safety training from his employer

and no specific instruction on how to avoid the hazards associated

with overhead powerlines.In this case, the company failed to obey these regulations:

|

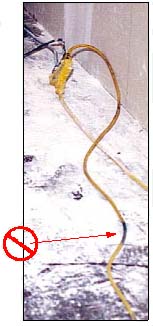

Defective insulation hazards

Insulation that is defective or inadequate is an electrical hazard. Usually, a plastic or rubber covering insulates wires. Insulation prevents conductors from coming in contact with each

other. Insulation also prevents conductors from coming in contact with people.

Extension cords may have damaged insulation. Sometimes the insulation inside an electrical tool or appliance is damaged. When insulation is damaged, exposed metal parts may become energized if a live wire inside touches them. Electric hand tools that are old, damaged, or misused may have damaged insulation inside. If you touch damaged power tools or other equipment, you will receive a shock. You are more likely to receive a shock if the tool is not grounded or double-insulated. (Double-insulated tools have two insulation barriers and no exposed metal parts.) You need to recognize that defective insulation is a hazard.

|

| This extension cord is damaged and should not be used. |

|

|

|

|

|

|

|

|

|

|

Improper grounding hazards

When an electrical system is not grounded properly, a hazard exists. The most common OSHA electrical violation is improper grounding of equipment and circuitry. The metal parts of an electrical wiring system that we touch (switch plates, ceiling light fixtures, conduit, etc.) should be grounded and at 0 volts. If the system is not grounded properly, these parts may become energized. Metal parts of motors, appliances, or electronics that are plugged into improperly grounded circuits may be energized. When a circuit is not grounded properly, a hazard exists because unwanted voltage cannot be safely eliminated. If there is no safe path to ground for fault currents, exposed metal parts in damaged appliances can become energized.

Extension cords may not provide a continuous path to ground because of a broken ground wire or plug. If you contact a defective electrical device that is not grounded (or grounded improperly), you will be shocked. You need to recognize that an improperly grounded electrical system is a hazard.

Electrical systems are often grounded to metal water pipes that serve as a continuous path to ground. If plumbing is used as a path to ground for fault current, all pipes must be made of conductive material (a type of metal). Many electrocutions and fires occur because (during renovation or repair) parts of metal plumbing are replaced with plastic pipe, which does not conduct electricity. In these cases, the path to ground is interrupted by nonconductive material.

A ground fault circuit interrupter, or GFCI, is an inexpensive life-saver. GFCI's detect any difference in current between the two circuit wires (the black wires and white wires). This difference in current could happen when electrical equipment is not working correctly, causing leakage current. If leakage current (a ground fault) is detected in a GFCI-protected circuit, the GFCI switches off the current in the circuit, protecting you from a dangerous shock. GFCI's are set at about 5 mA and are designed to protect workers from electrocution. GFCI's are able to detect the loss of current resulting from leakage through a person who is beginning to be shocked. If this situation occurs, the GFCI switches off the current in the circuit. GFCI's are different from circuit breakers because they detect leakage currents rather than overloads.

Circuits with missing, damaged, or improperly wired GFCI's may allow you to be shocked. You need to recognize that a circuit improperly protected by a GFCI is a hazard.

| If you touch a defective live component that is not grounded, you will be shocked. |

| GFCI—ground fault circuit interrupter—a device that detects current leakage from a circuit to ground and shuts the current off |

| leakage current—current that does not return through the intended path but instead "leaks” to ground |

| ground fault—a loss of current from a circuit to a ground connection |

| overload—too much current in a circuit |

| An overload can lead to a fire or electrical shock. |

Overload hazards

Overloads in an electrical system are hazardous because they can produce heat or arcing. Wires and other components in an electrical system or circuit have a maximum amount of current they can carry safely. If too many devices are plugged into a circuit, the electrical current will heat the wires to a very high temperature. If any one tool uses too much current, the wires will heat up.

|

Overloads

are a major cause of fires. |

The temperature of the wires can be high enough to cause a fire. If their insulation melts, arcing may occur. Arcing can cause a fire in the area where the overload exists, even inside a wall.

In order to prevent too much current in a circuit, a circuit breaker or fuse is placed in the circuit. If there is too much current in the circuit, the breaker “trips” and opens like a switch. If an overloaded circuit is equipped with a fuse, an internal part of the fuse melts, opening the circuit. Both breakers and fuses do the same thing: open the circuit to shut off the electrical current.

If the breakers or fuses are too big for the wires they are supposed to protect, an overload in the circuit will not be detected and the current will not be shut off. Overloading leads to overheating of circuit components (including wires) and may cause a fire. You need to recognize that a circuit with improper overcurrent protection devices—or one with no overcurrent protection devices at all—is a hazard.

Overcurrent protection devices are built into the wiring of some electric motors, tools, and electronic devices. For example, if a tool draws too much current or if it overheats, the current will be shut off from within the device itself. Damaged tools can overheat and cause a fire. You need to recognize that a damaged tool is a hazard.

|

| Damaged equipment can overheat and cause a fire |

| circuit

breaker—an overcurrent protection device that automatically shuts off the current in a circuit if an overload occurs |

| trip—the automatic opening (turning off) of a circuit by a GFCI or circuit breaker |

| fuse—an overcurrent protection device that has an internal part that melts and shuts off the current in a circuit if there is an overload |

| Circuit breakers and fuses that are too big for the circuit are dangerous. |

| Circuits without circuit breakers or fuses are dangerous. |

| Damaged power tools can cause overloads. |

| Wet conditions are dangerous. |

Wet conditions hazards

Working in wet conditions is hazardous because you may become an easy path for electrical current. If you touch a live wire or other electrical component—and you are well-grounded because you are standing in even a small puddle of water—you will receive a shock.

Damaged insulation, equipment, or tools can expose you to live electrical parts. A damaged tool may not be grounded properly, so the housing of the tool may be energized, causing you to receive a shock. Improperly grounded metal switch plates and ceiling lights are especially hazardous in wet conditions. If you touch a live electrical component with an uninsulated hand tool, you are more likely to receive a shock when standing in water.

But remember: you don’t have to be standing in water to be electrocuted. Wet clothing, high humidity, and perspiration also increase your chances of being electrocuted. You need to recognize that all wet conditions are hazards.

|

|

|

|

Additional hazards

In addition to electrical hazards, other types of hazards are present at job sites. Remember that all of these hazards can be controlled.

- There may

be chemical hazards. Solvents and other substances may be poisonous

or cause disease.

- Frequent

overhead work can cause tendinitis (inflammation) in your shoulders.

- Intensive

use of hand tools that involve force or twisting can cause tendinitis

of the hands,

wrists, or elbows. Use of hand tools can also cause carpal tunnel syndrome, which results when nerves in the wrist are damaged by swelling tendons or contracting muscles.

|

Overhead work can cause long-term shoulder pain. |

|

|

| Frequent

use of some hand tools can cause wrist problems such as carpal tunnel syndrome. |

|

| A 22-year-old

carpenter’s apprentice was killed when he was struck in the

head by a nail fired from a powder-actuated nail gun (a device

that uses a gun powder cartridge to drive nails into concrete

or steel). The nail gun operator fired the gun while attempting

to anchor a plywood concrete form, causing the nail to pass through

the hollow form. The nail traveled 27 feet before striking the

victim. The nail gun operator had never received training on how

to use the tool, and none of the employees in the area was wearing

PPE. In another situation, two workers were building a wall while remodeling a house. One of the workers was killed when he was struck by a nail fired from a powder-actuated nail gun. The tool operator who fired the nail was trying to attach a piece of plywood to a wooden stud. But the nail shot though the plywood and stud, striking the victim. Below are some OSHA regulations that should have been followed.

|

| PPE—personal protective equipment (eye protection, hard hat, special clothing, etc.) |

- Low back

pain can result from lifting objects the wrong way or carrying heavy

loads of wire or other material. Back pain can also occur as a result

of injury from poor working surfaces such as wet or slippery floors.

Back pain is common, but it can be disabling and can affect young

individuals.

- Chips and

particles flying from tools can injure your eyes. Wear eye protection.

- Falling objects

can hit you. Wear a hard hat.

- Sharp tools

and power equipment can cause cuts and other injuries. If you receive

a shock, you may react and be hurt by a tool.

- You can be

injured or killed by falling from a ladder or scaffolding. If you

receive a shock—even a mild one—you may lose your balance

and fall. Even without being shocked, you could fall from a ladder

or scaffolding.

- You expose yourself to hazards when you do not wear PPE.

|

|

| Lift with your legs, not your back! | You need to be especially careful when working on scaffolding or ladders. |

Summary of Section 5

You need to be able to recognize that electrical shocks, fires, or falls result from these hazards:

- Inadequate

wiring

- Exposed electrical

parts

- Overhead powerlines

- Defective

insulation

- Improper grounding

- Overloaded

circuits

- Wet conditions

- Damaged tools

and equipment

- Improper PPE