OSHA Guidance Document - Fall Protection in Residential Construction

Summary Statement

This OSHA guidance document is designed to help employers prevent fall-related injuries and fatalities among workers engaged in residential construction activities, such as roofing. Falls are the leading cause of work-related deaths among residential construction workers

December 16, 2010

Table of Contents

Executive Summary

Introduction

Installing Roof Trusses

Installing Ridge Poles and Rafters

Installing Roof Sheathing

Roofing – Weatherproofing

Foundation Walls and Formwork

Installing Floor Joists and Floor Trusses

Installing Subfloors

Installing Walls

Sheathing Walls

Exterior Finishing

Interior Finishing

More Resources

This OSHA guidance document is designed to help employers prevent fall-related injuries and fatalities among workers engaged in residential construction activities, such as roofing. Falls are the leading cause of work-related deaths among residential construction workers.

On December 16, 2010, OSHA issued STD 03-11-002, Compliance Guidance for Residential Construction, which rescinds STD 03-00-001, Interim Fall Protection Compliance Guidelines for Residential Construction, and provides that OSHA will be enforcing 29 CFR 1926.501(b)(13) for all residential construction work.

This guidance document is intended to assist employers with their compliance efforts. It provides information on various work methods that may be used at different stages of the residential construction process.

David Michaels, PhD, MPH

Assistant Secretary of Labor for

Occupational Safety and Health

| This document is intended to assist employers in their efforts to comply with fall protection requirements for residential construction work. The Occupational Safety and Health Act requires employers to comply with safety and health standards promulgated by OSHA or by a state with an OSHA-approved state plan. However, this document is not itself a standard or regulation and it creates no new legal obligations. |

Falls are the leading cause of death for workers engaged in residential construction. This “Fall Protection in Residential Construction” guidance document describes various methods that residential construction employers may be able to use to prevent fall-related injuries and fatalities at various points in the residential construction process.

The focus of this document is mostly on new construction. The examples provided in this guidance document do not represent all possible work methods that can be used in residential construction. Moreover, employers should be aware that the examples described in this document may not be suitable in all situations. Employers are responsible for ensuring compliance with applicable OSHA requirements.

Under 29 CFR 1926.501(b)(13), workers engaged in residential construction six (6) feet or more above lower levels must be protected by conventional fall protection (in other words, guardrail systems, safety net systems, or personal fall arrest systems) or other fall protection measures allowed elsewhere in 1926.501(b). (Although the standard does not mention personal fall restraint systems, OSHA will accept a properly utilized fall restraint system in lieu of a personal fall arrest system when the restraint system is rigged in such a way that the worker cannot get to the fall hazard.) If an employer can demonstrate that the fall protection required under 1926.501(b)(13) is infeasible or presents a greater hazard, it must instead implement a written fall protection plan meeting the requirements of 1926.502(k).

Fall protection used to comply with 1926.501(b)(13), including guardrail systems, safety net systems, and personal fall arrest systems, must meet and be used in accordance with applicable requirements in 1926.502. Requirements for work performed on scaffolds, ladders, and aerial lifts are in Part 1926 – Subpart L, Subpart X, and 1926.453, respectively.

State plans may also have additional requirements. For further information on state plan standards, please visit: http://www.osha.gov/dcsp/osp/statestandards.html.

Numerous methods can be used to prevent fall-related injuries and fatalities among workers installing roof trusses.

Bracket Scaffold

A bracket scaffold can be placed on the interior or exterior of a structure. The scaffold can provide a stable working platform. When bracket scaffolds are used on the interior of the structure, the exterior wall can limit employee exposures to fall hazards.

|

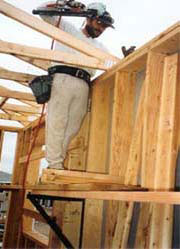

| Figure 1 - A worker installing roof trusses from an interior bracket scaffold. |

Exterior bracket scaffolds can also be used for installing roof trusses and other rooftop construction activities. The guardrail system on the scaffold can provide fall protection. With the addition of toeboards, falling object protection can be provided to the areas below.

|

| Figure 2 - Workers using an exterior bracket scaffold to install roof trusses. |

Ladders

Platform ladders and step ladders can provide a stable, elevated platform from which to work.

|

| Figure 3 - Platform ladders can be set up inside a structure and used to install roof trusses. |

Anchors

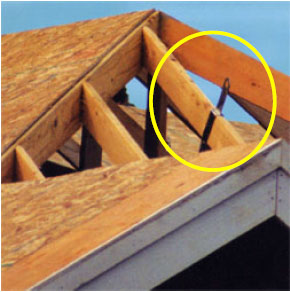

A spreader braces the trusses and distributes arrest forces across several trusses. Spreaders can act as anchors for personal fall arrest systems and fall restraint. They can be reused according to the manufacturer’s instructions. It is important to refer to the truss manufacturer’s instructions and have a qualified person determine if trusses will meet strength requirements for a personal fall arrest system or fall restraint system.

|

| Figure 4 – An example of a spreader attached to roof trusses. |

Installing Ridge Poles and Rafters

Although the use of roof trusses is nearly universal, some builders still frame roof systems with ridge poles and rafters. While performing this task, workers need to be protected from falls.

Anchors

Employees installing ridge poles and rafters can use strap anchors and bolt-on anchors. These anchors can be used with personal fall arrest systems and fall restraint to provide fall protection for workers engaged in this activity. Both anchors can be removed and reused according to the manufacturer’s instructions.

|

| Figure 5 - Strap anchors providing anchorage for three personal fall arrest systems. |

|

| Figure 6 - A bolt-on anchor attached to a rafter. |

Once a roof has been framed, roof sheathing operations can begin. There are serious fall hazards associated with this activity, but there are a number of ways to protect workers.

Safety Net System

Safety net systems can be used as fall protection for workers installing roof sheathing.

|

| Figure 7 - An example of a safety net system. |

Bracket Scaffold

A bracket scaffold can be attached to the top plate of a structure. The scaffold can provide a secure work platform from which to install roof sheathing.

|

| Figure 8 – A worker sheathing a roof from a bracket scaffold. |

Anchors

Anchors and retractable lifeline stands can be used by workers installing roof sheathing.

|

|

| Figure 9 - Anchors that can be used while performing roof sheathing operations. | |

As with other roofing activities, fall protection is critical for this type of work.

Bracket Scaffolds

An exterior bracket scaffold can be used for workers weatherproofing a roof. Bracket scaffolds can be especially useful for installing materials along the edge of the roof. Some exterior bracket scaffolds can be used as catch platforms to prevent workers from falling six feet to the lower level.

|

| Figure 10 - An exterior bracket scaffold with guardrails being used to protect workers while weatherproofing. |

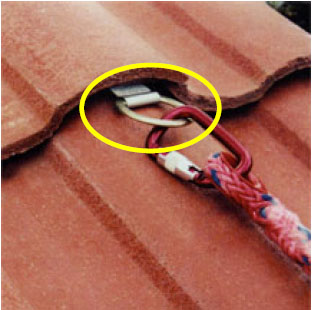

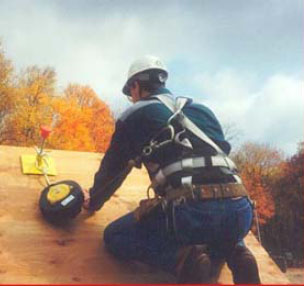

Anchors

Permanent anchors can be installed during roofing operations and left in place after construction is complete. They can provide an anchorage point during the life of the roof. Reusable anchors can also be used while weatherproofing a roof. It is important to inspect these anchors prior to use.

|

|

| Figures 11 & 12 - Permanent anchors on completed roofs. | |

|

| Figure 13 - A worker using a reusable anchor with a retractable lifeline. |

In most residential construction, concrete or masonry block is used to create the foundation and the foundation walls of a structure. The concrete is usually poured into an excavation to create the foundation and the foundation walls.

Anchors

Anchors can be added to cured concrete. Anchors with expandable bolts can be placed in holes that have been drilled into the concrete.

|

| Figure 14 – A cutaway picture of an anchor with an expandable bolt for use in concrete. |

Strap anchors can provide versatility and options for anchorage points while performing this type of work. Strap anchors can be looped over rebar and removed when no longer necessary.

|

| Figure 15 - A worker placing a strap on anchor over rebar. |

These strap anchors can also be poured over with concrete and left in during construction. Antichafe sleeves (the green part of the anchor) can be used to maintain the integrity of the strap. Once no longer needed, the strap can be cut out of the concrete and removed.

Anchor straps are typically reusable if they have not been poured into concrete or have not been shock loaded. Please refer to the manufacturer’s instructions when using this equipment.

Scaffolds

Scaffolds can provide elevated work surfaces for workers performing foundation work.

|

| Figure 16 - A bracket-form scaffold attached to formwork. |

Installing Floor Joists and Floor Trusses

Floor joists and floor trusses are usually constructed directly over the foundation walls. Fall hazards may be present, for example, if the structure being built has a basement.

Anchors

A reusable floor truss anchor can act as a temporary truss brace and spacer as well as an anchor point for a self-retracting lifeline. The device can spread shock loads over multiple trusses. These kinds of anchors can be uninstalled, moved, reinstalled and reused as per the manufacturer’s instructions.

|

| Figure 17 - A retractable lifeline attached to a floor truss anchor. |

Scaffolds

Scaffolds can be used for residential construction workers installing floor joists and floor trusses.

Mobile scaffolds can be used effectively for residential construction workers. These scaffolds can be placed on the cured concrete basement floor of a structure. From the elevated platforms of the mobile scaffold, workers can install carrier beams, floor joists, and floor trusses.

|

| Figure 18 - Workers installing a steel beam from a mobile scaffold. |

Wall bracket scaffolds can be used on a residential structure once a wall has been completed. These scaffolds can provide access around the perimeter of the structure and can be used by workers while they install carrier beams, floor joists, and floor trusses. This type of scaffold can also be used in other phases of residential construction.

|

| Figure 19 – A scaffold rigged for installing floor joists and floor trusses. |

Subfloors are usually installed by fastening a wood deck to floor joists and floor trusses. Because of the openings between floor joists and floor trusses, fall hazards may exist while performing this task.

Anchors

A truss bracket anchorage system can distribute the arresting forces across multiple trusses in the event of a fall. When appropriately installed in accordance with the manufacturer’s instructions, these anchors can be used with personal fall arrest systems and fall restraints. Because these anchors are reusable, they can be uninstalled and reinstalled in accordance with the manufacturer’s instructions.

|

| Figure 20 - Workers using a truss bracket anchor while installing a subfloor. |

Guardrails

Guardrail systems can be used to protect workers from falls during the performance of flooring and subflooring activities. If installed with a toeboard, guardrail systems can also protect workers on lower levels from falling objects.

|

|

| Figures 21 & 22 - Examples of guardrails installed around floor openings. | |

Framed wall sections usually are constructed on the ground and typically include sheathing and openings for windows and doors. Guardrails across these openings can help prevent falls while work is being performed in the house after the walls have been erected. These walls can be erected by using a lifting device such as a crane, boom truck, or forklift. Jacks can also be used to raise these walls. These practices greatly reduce the likelihood that a worker will be exposed to a fall during this stage of construction.

|

| Figure 23 - Framed walls being erected using a jack. |

For workers exposed to falls while framing walls, there remain various ways of protecting against falls to lower levels.

Anchors

Some models of strap anchors are looped through soft eyes or larger D rings and can be uninstalled, moved, reinstalled and reused following the manufacturer’s instructions.

|

| Figure 24 - A reusable strap anchoring a retractable lifeline. |

Strap anchors can also be preinstalled to provide an anchorage point once the walls have been erected and braced. They can be removed by cutting the strap off or pulling out the nails. Once cut or nailed, these must not be reused without being refurbished by the manufacturer.

|

|

| Figures 25 & 26 - Reusable anchors | |

Guardrails

Guardrail systems can provide fall protection while workers are framing walls.

|

| Figure 27 - Worker installing guardrails. |

Although it is common for sheathing to be included on panelized walls used in residential construction, sheathing still takes place on residential construction sites. Erecting the walls by lifting devices or jacks can lessen a worker’s exposure to fall hazards.

Scaffolds

Welded End Frame (X brace) scaffolds (like tube/coupler, and systems scaffolds) stand on their own. With proper bracing, the frames can be stacked from cellar hole to chimney top. Like other scaffolds, these can make stable work platforms for many residential construction operations. These stand-alone scaffolds can be used for sheathing and various other vertical wall operations such as masonry wall construction, siding, and stucco application.

|

| Figure 28 - Welded end frame scaffold. |

Exterior bracket scaffolds can provide a work surface from which to attach sheathing to the frame.

|

| Figure 29 – A worker sheathing walls from an exterior bracket scaffold. |

A ladder jack scaffold consists of a platform resting on brackets attached to a ladder. Ladder jacks provide limited elevation and are primarily used in light applications because of their portability and cost-effectiveness.

Aerial Lifts

Aerial lifts may be used for wall sheathing work. In particular, boom type elevating and rotating aerial work platforms can offer positioning flexibility and provide stable elevated platforms.

|

| Figure 30 - Worker performing residential construction activities from an aerial lift. |

The exterior finishing phase of residential construction includes a number of activities, such as installing windows, doors, siding, and gutters. Many of these tasks pose fall hazards.

Aerial Lifts

Aerial lifts can be ideal equipment for exterior finishing. By providing a stable, level work surface and positioning flexibility, an aerial lift can be used for numerous activities associated with finishing the exterior of a residential construction structure.

|

| Figure 31 - Worker positioning an aerial lift. |

Ladders

Ladders can provide access to areas of a structure where exterior finishing work will occur. They can provide a stable work surface for various exterior finishing tasks.

Scaffolds

Pump jack scaffolds consist of a platform supported by moveable brackets on vertical poles. Pump jacks are appealing for certain applications because they are easily adjusted to variable heights, and are relatively inexpensive. They can include a material shelf for carrying supplies and tools.

|

| Figure 32 - A worker performing siding activities from a pump jack scaffold. |

Although much of this work may take place while exterior finishing is happening, interior finishing is one of the last phases of residential construction. This does not mean that fall hazards are no longer present.

Guardrails

Guardrails can be an excellent option for providing fall protection for work on or near stairways and landings. The addition of a toeboard can also prevent objects from falling to lower levels.

|

| Figure 33 - Wooden guardrail system for a stairway. |

|

| Figure 34 - A landing protected by a wooden guardrail system with a toeboard. |

|

| Figure 35 - Guardrails protecting window openings. |

STD 03-11-002, Compliance Guidance for Residential Construction - http://www.osha.gov/pls/oshaweb/owadisp.show_document?p_table=DIRECTIVES&p_id=4755

Fact Sheet on Fall Protection in Residential Construction - http://www.osha.gov/doc/fall_protection_factsheet.html

Residential Construction Q & A’s - http://www.osha.gov/doc/residential-construction/residential-construction-qa.html