Summary Statement

Images of an oxygen cylinder that exploded along with a description of the factors that led to the incident.

Airgas-Safecore

- Improper methods used to render scrap cylinder unserviceable

- Unsafe modifications to cylinder design

Accident Profile

- Two individuals (ages 42 and 60) found a liquid oxygen cylinder that had been removed from service and left at a scrap metal dealer

- The individuals were self-employed in scrap metal cutting operations and intended to use the cylinder in their work

- The individuals had access to a liquid oxygen supplier where cylinder ownership would not be questioned

- Jury-rigging fill connections, the first attempt to fill the cylinder resulted in rapid venting through the Pressure Relief Device (PRD)The PRDs were removed and plugged

- The cylinder was filled while onboard a pickup truck

- The cylinder, which had no vacuum, was now unable to vent excess pressure

- While being transported down a busy highway, the pickup truck experienced a flat tire

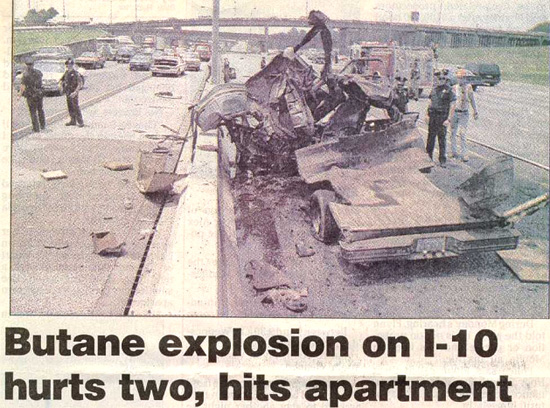

- Shortly thereafter, the cylinder exploded with the results shown in the following slides

Pickup and cylinder remains

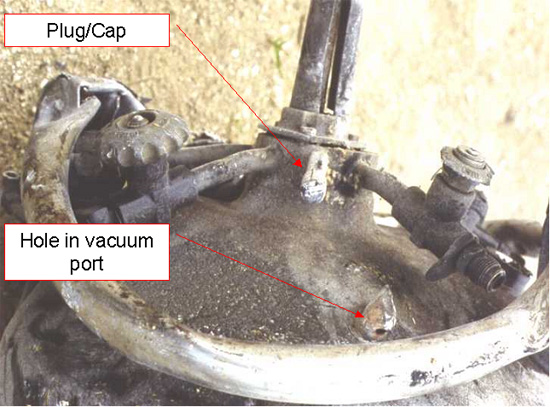

Cylinder top

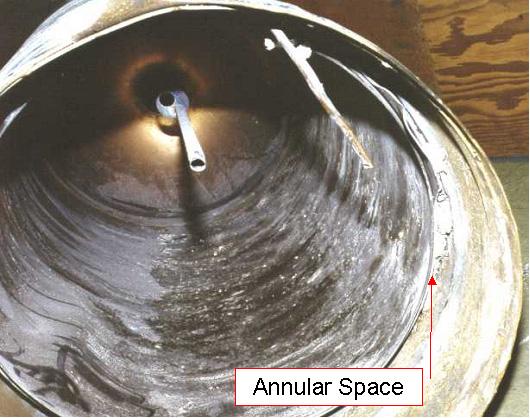

Cylinder outer shell, bottom

Cylinder bottom shell

PRD location was plugged using a threaded cap

Both inner and outer shells separated at bottom welds

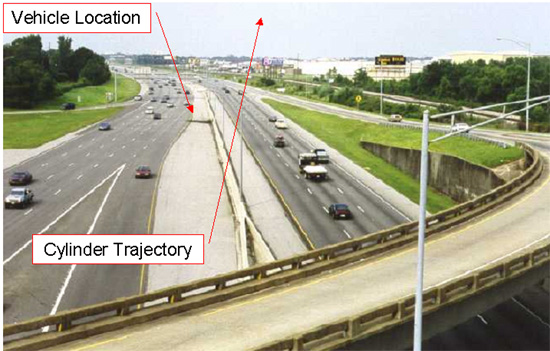

Cylinder exploded at 12:40 PM while transport vehicle was parked on busy Interstate highway

The blast blew one individual across 5 lanes of traffic. The other was blown approximately 40 feet. Both survived

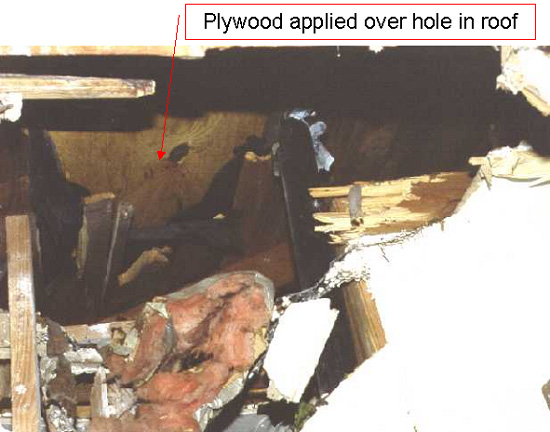

Cylinder flew approximately ¼ mile before plunging through the roof of an apartment, severing a main natural gas line and coming to rest in the living space

Despite heavy damage, no injuries to apartment tenants were reported

Apartment interior

Note that the media reported the event as a Butane cylinder explosion