Summary Statement

Describes a process to reduce noise exposure by defining a noise perimeter zone, keeping workers out of the zone who do not need to be there, and using engineering controls and hearing protection.

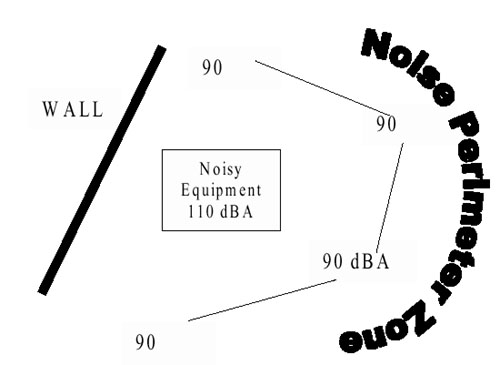

Noise Perimeter Zones

One way to make sure that as few workers as possible are exposed to loud noise is to post a "Noise Perimeter Zone" around loud equipment. This means that places where noise levels are 90dBA or more roped off and marked to keep out all workers who don't have to be there.Using a sound level meter, the safe distance from the source of the noise can be measured and Noise Perimeter Zones can be set up at that distance. Noise radiates from the source of the noise, but not at the same level in all directions. Noise from machinery can be higher in one direction than another. The noise can also be either absorbed or deflected from the surfaces it contacts, such as the ground or a wall. Measurements can be taken at several points in an area where people might be working. Determine the points where the noise levels are 90 dBA or more and rope off this area as the Noise Perimeter Zone. Exclude all workers who do not need to be in that zone. All workers who need to work within the zone must wear hearing protection. The area can be marked "Noisy Area - Hearing Protection Required" in the same way that a "Hard Hat Area" is marked off.

Of course, that entire

site can be inside a Noise perimeter Zone. Then everyone on site must

wear hearing protection.

For more information on community noise regulations which apply to construction

equipment see: http://www.nonoise.org/resource/construc/bigdig.htm

Engineering Controls

- Install high-quality

mufflers/silencers on engine-powered equipment.

- Replace worn,

loose, or unbalanced machine parts that cause vibration.

- Keep machine

parts well lubricated to reduce friction.

- Erect acoustical

enclosures and barriers around generators.

- Install sound absorbing material and vibration isolation systems on hand tools.

Hearing Protectors

Each hearing protection

device (HPD) has a Noise Reduction Rating (NRR) assigned by the manufacturer.

These NRRs show how much the muffs or plugs reduce the noise and are the

result of laboratory tests. Tests in the real world have shown that the

noise reduction is much lower. Therefore OSHA compliance officers consider

the true noise reduction to be about one-half of the NRRs on the labels.

Independent tests have shown that earmuffs provide the highest real-world

noise reductions, followed by foam earplugs.

Hearing protectors must also be comfortable to wear. NIOSH says that "the best hearing protector is the one that the worker will wear."

Administrative Controls

Limit the Time of

Exposure

To keep within the OSHA noise limits for construction you can limit the

amount of time a worker is exposed to noise:

|

Noise

level (dBA)

|

Maximum

exposure time per day

|

|

85

|

16

hours

|

|

90

|

8

hours

|

|

95

|

4

hours

|

|

100

|

2

hours

|

|

105

|

1

hour

|

|

110

|

30

minutes

|

This table assumes that there is minimal noise exposure for the rest of the day!

Turn off equipment

not in use.

Many times machinery and equipment are left running even though nobody

is using them. Every piece of running equipment contributes to the noise.

Turn it off!