International Social Security Association Construction Awareness

Summary Statement

This PowerPoint was developed by CPWR - The Center for Construction Research and Training for the International Social Security Association (ISSA) to highlight the international importance of the construction sector and the elevated risks to workers in the field. The program is modeled on a previous ISSA PowerPoint for the mining industry, which featured strong photos and limited copy. The mining program promoted an ISSA safety initiative called Vision Zero; this program promotes the 2014 guidance from CPWR and NIOSH on strengthening jobsite safety climate.

10-19-15

A New Strategy for Protecting Construction Workers

-ISSA Construction 10-19-2015

Construction is BEAUTIFUL

Photo of Smithsonian National Museum of the American Indian

courtesy Wikimedia Commons and the Smithsonian Institute.

Photographer: Carol M. Highsmith.

This newest addition to the Smithsonian museums on the mall was built with union labor.

Construction is COMPLEX.

Photo is the Las Vegas City Center. Courtesy Wikimedia

Commons and Wladimir Labeikovsky.

Construction is SKILLED

Photo courtesy of International Brotherhood of Boilermakers.

Construction is DIVERSE

Photo courtesy Chicago Women in Trades.

Construction is ESSENTIAL

Photo courtesy of International Brotherhood of Boilermakers.

Construction is DYNAMIC

Photo courtesy of International Brotherhood of Boilermakers.

Construction is HIGH-TECH.

Photo courtesy of International Brotherhood of Boilermakers.

Construction is INFRASTRUCTURE.

Photo courtesy Earl Dotter and CPWR.

Construction is POWERFUL.

E66 Wind Turbine Rotor Detail. Photo courtesy Wikimedia Commons and Daniel Arnold -

Photo Licensed under CC BY-SA 3.0 via Wikimedia

Commons. E66-wind-turbine-rotor-detail-16-05-2005.

Construction is TEAMWORK.

Photo courtesy International Union of Operating Engineers

and Neil W. Lippy.

But construction has other faces.

Construction ENDANGERS.

Photo: 2nd place in OSHA’s 2011 photo contest. Courtesy

Roberto Carlos Vergara of Charlotte, North Carolina.

Construction EXPOSES.

Photo courtesy CCBC and Neil W. Lippy.

Construction SICKENS.

Photo of asphalting a road with its fumes and workman standing by. Photo courtesy CPWR’s electronic Library of Construction

Safety and Health (eLCOSH).

Construction DAMAGES.

Photo courtesy CPWR’s electronic Library of Construction

Safety and Health (eLCOSH).

Construction HURTS.

Photo courtesy CPWR’s electronic Library of Construction

Safety and Health (eLCOSH) and Earl Dotter.

Construction KILLS.

Photo courtesy CPWR’s electronic Library of Construction

Safety and Health (eLCOSH).

Let's talk about SAFETY.

Risks are different in construction.

Photo courtesy Wikimedia Commons.

Bystander exposures are much more prominent.

Photo courtesy eLCOSH and Neil W. Lippy.

Multi-employer worksites complicate communication.

Photo courtesy eLCOSH.

Conditions change daily.

Nearly half of construction workers reported being very hot or very cold at least once a week.1

Photo courtesy International Union of Operating

Engineers and Neil W. Lippy.

Photo courtesy the International Union of

Operating Engineers and Neil W. Lippy.

More than half of construction workers reported exposure to vapors, gas, dust or fumes twice a week or more.

Photo courtesy George Washington

University and the Whiting Turner

Construction Company.

In 2010, more than 50 percent of construction workers reported that they were regularly exposed to vapors, gas, dust or fumes at work twice a week or more, which was more than double that of all industries combined. Construction workers, representing only five to six percent of the non-farm labor force, account for half of all occupational cancers.2

Photo courtesy eLCOSH and Mt. Sinai School of Medicine.

Construction workers are 5-6% of non-farm labor force, but account for half of all occupational cancers.3

828 U.S. construction workers died on the job in 2013. The highest count of fatal injuries among U.S. sectors.4

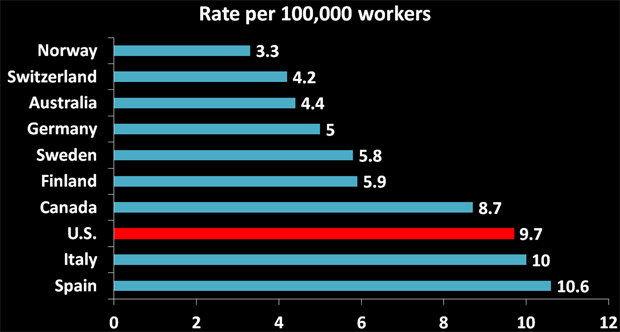

The rate of deaths from injuries in construction is higher in the U.S. than in many industrialized countries (2008).

In 2008, construction fatal injury rates among selected industrial countries ranged from 3.3 to 10.6 deaths per 100,000 workers (chart 37a). The reported construction fatality rate in the United States was relatively high, at 9.7 deaths per 100,000 full-time equivalent workers (FTEs, see Glossary) – only slightly lower than the rates for Spain and Italy, but nearly triple the rate for Norway.

5Source: CPWR, The Center for Construction Research and Training. [2013, April].

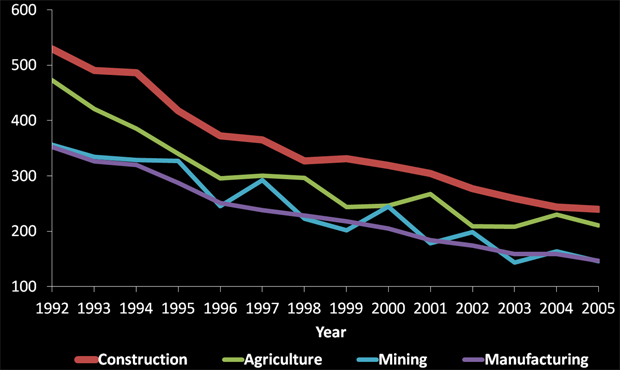

Construction led other U.S. sectors in the rate of nonfatal injuries and illnesses with days away from work 1992-2005 (Private wage-and-salary workers).

5Source: CPWR Construction Chart Book, April, 2013.

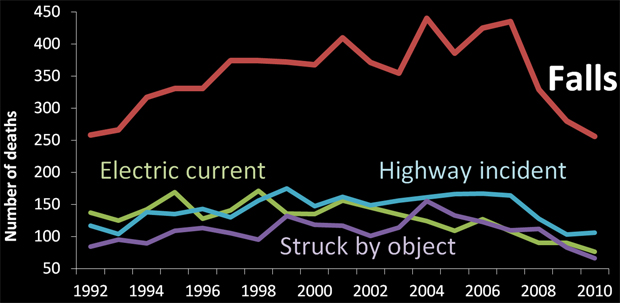

Falls are still the leading cause of death on U.S. construction projects.

5Source: CPWR Construction Chart Book, April, 2013.

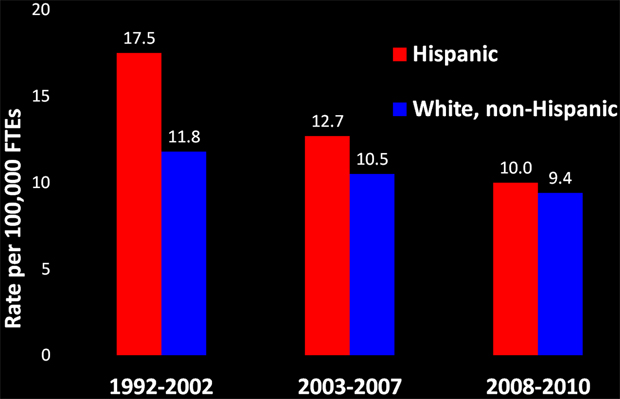

Hispanic construction workers die at a higher rate than white, non-Hispanic workers.

Rate of fatalities in construction,

by Hispanic ethnicity, 1992-2010 (All employment).

5Source: CPWR Construction Chart Book, April, 2013.

Latino workers often face fall hazards.

Photographs courtesy Robert Carr. California, 2006.

The photographer, Robert Carr, described the work scene below in his own words and noted that one of these three nearly fell while he photographed this work:

"These photos show three roofers at the edge of roof, without fall protection, lifting and tying off flared top of trash chute with which to funnel old roofing material into dump truck for disposal. The crew is using two pitch forks (hand tools for roof demolition) to pry the top flared part of the chute over and above the roof edge and gutter. The worker on the right shortly thereafter lost his balance but recovered and sat down on roof, rather than pitching over the roof edge and falling two floors. The workers returned the next day to demolish the roof, including near edge, and walk along the edge of the roof to drop debris into chute. They should all be wearing body harnesses, with lanyards tied back with safety line to a secure support near center of roof."

A strategy for construction

Logo Courtesy of ISSA-Mining.

We need a strategy for construction safety. Mining has a program called "Vision Zero." Vision Zero has 7 golden rules covering these fields of action: (1)technology, (2) workplace (3) rules, (4) people

Similarly, CPWR and NIOSH have developed, "Strengthening Jobsite Safety Climate, 2014," which is a document containing indicators similar to the 7 Golden Rules of ISSA's Vison Zero.

6Strengthening Jobsite Safety Climate, 2014

A company can check these indicators for guidance in strengthening its jobsite safety climate. It can be accessed at: http://www.elcosh.org

There are 8 leading indicators to check

These are the 8 indicators:

- Demonstrate Management Commitment.

- Align and Integrate Safety as a Value.

- Ensure Accountability At All Levels.

- Improve Supervisory Leadership.

- Empower and Involve Workers.

- Improve Communication.

- Train at All Levels.

- Encourage Owner and Client Involvement.

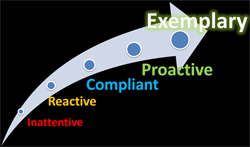

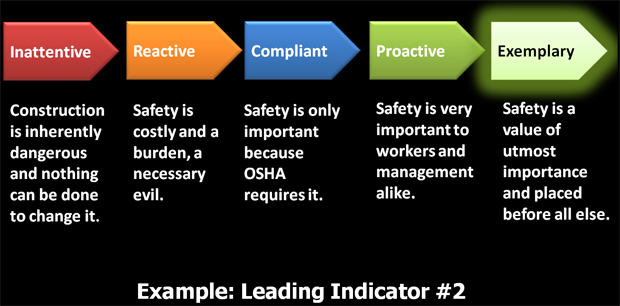

Each indicator has its own worksheet. Within the document, companies can check where they are on the path to an exemplary safety climate.

Is the company (in increasing levels of desirability): (1) inattentive, (2) reactive, (3) compliant, (4) proactive, or (5) exemplary? See Indicator #2. How well does your firm Align and Integrate Safety as a Value?

Leading Indicators

Photo courtesy Earl Dotter.

1- Demonstrate Management Commitment.

Management:

- Is present and visible on job sites

- Practices safe behaviors on job sites

- Identifies and eliminates or at least reduces hazards

- Has a respectful process for corrective action

- Has a respectful reaction to worker injuries

- Reviews and analyzes safety policies, procedures & trends

2- Align and Integrate Safety as a Value.

Photo courtesy of International

Brotherhood of Boilermakers.

- Safety is: Discussed at all regularly scheduled meetings, Aligned with other values such as productivity and cost reduction, and Integrated into all organizational policies & procedures.

- Leading safety indicators are used to improve jobsite safety climate.

- Adequate resources are allocated for safety program and safety activities.

Photo courtesy of International

Brotherhood of Boilermakers.

3- Ensure Accountability At All Levels.

Element 3 is Ensuring Accountability at All Levels.

- A system of safety accountability is created for:

- Workers,

- Managers and supervisors, and

- Project owners.

- Policies setting safety goals, roles and responsibilities for a positive jobsite safety climate are established.

- An incentive structure that promotes and rewards safety processes not just outcomes is developed.

4- Improve Supervisory Leadership.

Photo courtesy: J. Vinton Schafer & Sons, Inc.

and CCBC Catonsville Campus

Element 4 is Improving Site Safety Leadership.

- Supervisors and foremen share a vision and a commitment to safety.

- Supervisor safety leadership is supported with training.

- Leaders are expected to lead by example, coach, and motivate others when it comes to safety.

5- Empower and Involve Workers.

Photo courtesy IBEW Local 26 and NECA’s Joint

Apprenticeship and Training Committee, Lanham, MD.

Element 5 is Empowering and Involving Workers.

- Workers are empowered to invest in safety for themselves and fellow coworkers.

- Worker input is sought on hazard reduction and safety improvement.

- Joint worker-management committees are relied upon to address safety and health concerns.

6- Improve Communication.

Photo courtesy Balfour Beatty.

Element 6 is Improving Communication.

- Open lines of communication between employees and all levels of management are established and maintained.

- All employees and managers receive safety trend reports.

- Process for communicating safety messages across entire organization is robust.

7- Train at All Levels.

Photo courtesy IBEW Local 26 and NECA’s Joint Apprenticeship

and Training Committee, Lanhan, MD.

Element 7 is Training at All Levels.

- Safety training for workers, supervisors, and managers is ongoing.

- Workers have OSHA-10 certificates and supervisors have OSHA-30 plus the STS certification.

- Training curriculum is tailored to specific roles and responsibilities at each level of the organization.

- Formal and informal assessments are conducted of training needs.

- Training knowledge and certificates are verified for all employees and contractors.

- Safety training is delivered by highly qualified experts.

8- Encourage Owner and Client Involvement.

Photo courtesy of Balfour Beatty.

Element 8 is Encouraging Owner and Client Involvement.

- Owners are visible on the jobsite.

- Contractors are held accountable for safety.

- Safety is a priority when selecting contractors.

- Prevention through Design (PtD) principles are used to prevent jobsite hazards.

- Incentives are aligned with safety.

Questions?

Contact CPWR

CPWR- The Center for

Construction

Research and Training

8484 Georgia Avenue,

Silver Spring, MD, USA

http://www.cpwr.com

301-578-8500

References

1Data from: Liss GM, Petsonk EL, Linch KD [2010, Nov]. The construction industry. In: Occupational and Environmental Lung Diseases: Diseases from Work, Home, Outdoor, and Other Exposures. Eds: Tarlo S, Cullinan P, & Nemery B, eds., Hoboken, NJ: John Wiley & Sons, Ltd. 273-289.

2CPWR, The Center for Construction Research and Training. [2013, April]. The construction chart book. Online. Available at: http://www.cpwr.com. p. 35.

3CPWR’s Construction Chart Book, 2013.

4Source: U.S. Bureau of Labor Statistics

5CPWR, The Center for Construction Research and Training. [2013, April]. The construction chart book. Online. Available at: http://www.cpwr.com

6Strengthening Jobsite Safety Climate, 2014. Accessed at: http://www.elcosh.org