Summary Statement

Brief description of the inspection process that should be gone through before each work shift to ensure that there are no hazards related to the scaffold.

Inspect scaffolds and scaffold parts daily, before each work shift, and after any event that may have caused damage.

- Check to see if powerlines near scaffolds are de-energized or that the scaffolds are at least 10 feet away from energized powerlines.

- Make sure that tools and materials are at least 10 feet away from energized powerlines.

- Verify that the scaffold is the correct type for the loads, materials, employees, and weather conditions.

- Check footings to see if they are level, sound, rigid, and capable of supporting the loaded scaffold.

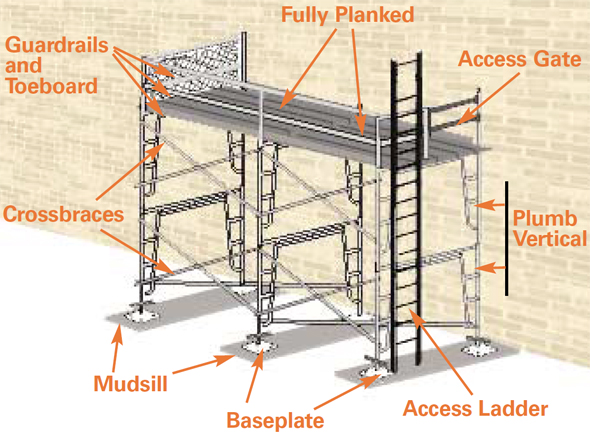

- Check legs, posts, frames, and uprights to see if they are on baseplates and mudsills.

- Check metal components for bends, cracks, holes, rust, welding splatter, pits, broken welds, and non-compatible parts.

- Check for safe access. Do not use the crossbraces as a ladder for access or exit.

- Check wooden planks for cracks, splits greater than one-quarter (1/4) inch, end splits that are long, many large loose knots, warps greater than one-quarter (1/4) inch, boards and ends with gouges, mold, separated laminate(s), and grain sloping greater than 1 in 12 inches from the long edge and are scaffold grade lumber or equivalent.

- If the planks deflect one-sixtieth (1/60) of the span or 2 inches in a 10-foot wooden plank, the plank has been damaged and must not be used.

- Check to see if the planks are close together, with spaces no more than 1 inch around uprights.

- Check to see if 10-foot or shorter planks are 6 to 12 inches over the center line of the support, and that 10-foot or longer planks are no more than 18 inches over the end.

- Check to see if the platform is 14 inches or more away from the wall or 18 inches or less away if plastering or stucco.

- Check for guardrails and midrails on platforms where work is being done.

- Check for employees under the platform and provide falling object protection or barricade the area. Make sure that hard hats are worn.

- Use braces, tie-ins and guying as described by the scaffold's manufacturer at each end, vertically and horizontally to prevent tipping.