Summary Statement

This 2010 program called DROPS was established by Chevron to prevent injuries to workers and damage to offshore oil rigs from objects dropped from elevated work stations.

January 2010

Dropped Objects Prevention

Deepwater Exploration/Projects SBU

Operational Excellence: One Team, One Goal, Incident-Free Operations (IFO)

Historically, dropped objects have played a principal role in oil and gas incidents. This situation should not be tolerated or allowed to continue. We must eliminate this type of incident.

Dropped objects is a collective issue and not just an operator or a rig owner’s problem; it is a common problem for everyone in our industry.

It occurs in most areas of the oil and gas industry, including fixed installations, mobile drilling units and land rigs and in all areas of our supply chain, including the office.

The solution is not an individual one, but a common solution, one that can be practiced by everyone who is involved in our industry.

Joint Health Environment Safety Improvement Team

Chevron values the safety of all workers and the protection of the environment.

Chevron is committed to Incident-Free Operations (IFO), but this can be achieved only by working as a team with our contractors.

Chevron wishes to acknowledge the valued contribution made by its contractors and the Dropped Objects Prevention Scheme (DROPS) in the production of this book.

Operational Excellence

One Team, One Goal, Incident-Free Operations (IFO)

Operational Excellence: Tenets of Operation

Two Key Principles

- Do it safely or not at all.

- There is always time to do it right.

We will ALWAYS:

- Operate within design and environmental limits.

- Operate in a safe and controlled condition.

- Ensure safety devices are in place and functioning.

- Follow safe work practices and procedures.

- Meet or exceed customer’s requirements.

- Maintain integrity of dedicated systems.

- Comply with all applicable rules and regulations.

- Address abnormal conditions.

- Follow written procedures for high risk or unusual situations.

- Involve the right people in decisions that affect procedures and equipment.

Stop Work Authority

Stop Work Authority (SWA) is the responsibility and authority of any individual to stop work when an unsafe condition or act could result in an undesirable event. By failing to exercise SWA when needed, your behavior sends the message that the practice is acceptable.

Contents

1.0 Purpose2.0 Scope

3.0 Goal/Objective

4.0 Definition

5.0 Why Focus on Dropped Objectives?

6.0 Dropped Objects Manifest Themselves in Many Ways

7.0 Strategy

8.0 Some Examples of Risk Areas

9.0 What Creates Dropped Objects?

10.0 What are the Effects of a Dropped Object?

11.0 The DROPS Calculator

12.0 Recommended Actions

13.0 Secondary Retention

14.0 How Can I Personally Prevent Dropped Objects?

15.0 Chevron Hazard ID Tool: A 360-Degree Approach

16.0 Part of a Complete Safety Package

-

16.1 Hazard Hunt Using the Hazard ID Tool

16.2 What is a Hazard?

16.3 What to do Following a Hazard Hunt

16.4 Inspections

16.5 Temporary Equipment

18.0 Pre-Job Risk Assessment

19.0 References

Note: The mention of any product or company in this handbook does not constitute an endorsement.

1.0 Purpose

To describe measures to prevent the occurrence of dropped objects, align with industry best practices and meet legislative requirements.

2.0 Scope

This booklet describes the management of objects that could fall and harm people or damage property during operations performed on all facilities under Chevron operational control. Specific reference is made to the Chevron Global Dropped Objects Management Guidelines (Issue 2010) and cross-industry Dropped Objects Prevention Scheme.

3.0 Goal/ Objective

The objective of this booklet is simple guidance to eliminate dropped objects through:

- Identification and understanding of potential workplace dropped objects hazards

- Creation of a dropped objects work group

- Understanding the various levels of protection that are available to prevent dropped objects

- Selecting and supplying the right level of mitigation

- Raising the overall awareness of dropped objects

The contents of this booklet apply to all Chevron personnel, contractors and subcontractors working on sites under Chevron operational control.

4.0 Definition

A dropped object is:

“Any object, with the potential to cause death, injury or equipment/environmental damage, that falls from its pre- vious static position under its own weight.”

When referring to dropped objects, consider:

- Hand tools being used at heights

- Hand tools/equipment left behind after working at height

- Operations conducted at height

- Equipment mounted at a height that, following contact, vibration or environmental conditions, could fall, i.e., piping, lights, cameras, rigging gear, etc.

- Temporary equipment at height

- Where personnel are working on a level directly below the work site

- Lifting operations

5.0 Why Focus on Dropped Objects?

Dropped objects are regularly the principal causes of incidents in the oil and gas industry and contribute to the total risk level for offshore and onshore facilities.

The consequences of a falling object include:

- Personal injury/death

- Structural damage

- Damage to equipment

- Release of hydrocarbons/fire

6.0 Dropped Objects Manifest Themselves in Many Ways

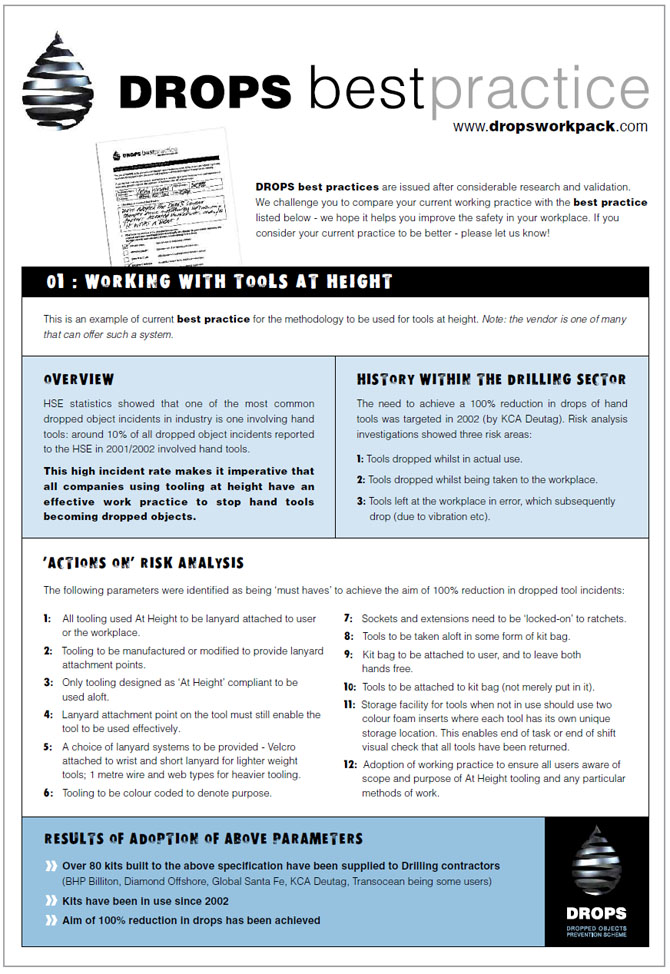

The following photographs show items found during Hazard Hunts.

7.0 Strategy

- Create site-specific dropped objects work groups.

- Identify and assess problem areas.

- Develop and implement an action plan.

- Monitor results.

- Continually improve.

8.0 Some Examples of Risk Areas

- Rig derricks/drill floor

- Areas below lifting operations

- Cranes

- Elevated work areas or platforms

- Work spaces where equipment is mounted overhead

- Temporary/portable equipment

- Remotely operated vehicles (ROVs)

- Vessels/barges

- Pipe racks

- Forklift trucks

- Poor stacking of materials

- Ladders

- Scaffolding

These are two examples of Risk Areas.

9.0 What Creates Dropped Objects?

- Poor housekeeping

- Scrap and debris left aloft

- No inspection

- No equipment maintenance

- Poor designs

- Weather

- No restraints

- No planning

- Load miscalculation

- Lack of risk assessment

- Errors in space requirements

- Instability

- Ineffective control of equipment or tools taken aloft

- No lanyards on tools used at height

- Improperly secured or inappropriate loads

- No regular inspection procedures

- Becoming blind to changes in activity (dynamic risk assessment)

- Carrying equipment while at height

10.0 What are the Effects of a Dropped Object?

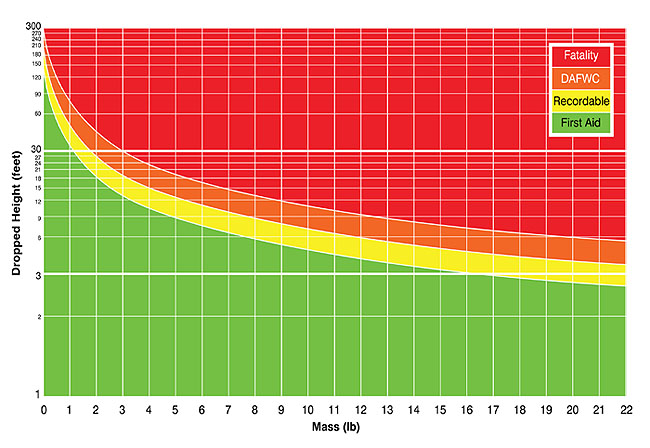

Even a small object falling from a height can cause serious or fatal injuries.

The potential harm to the individual has been determined using the Dropped Objects Calculator.

The Dropped Objects Calculator was developed with a mathematical model based upon the mass of the object and the height from which it falls.

This calculator and other resources can be found at:

11.0 The DROPS Calculator

12.0 Recommended Actions

- Create a dropped objects work group specific to the site.

- Complete a derrick or work site dropped objects inventory with the Chevron HAZARD ID tool.

- Use the inventory to develop an inspection program.

- Introduce working at height procedures.

- Introduce specific toolkits for working at height. Implement processes to account for tools.

- Raise overall dropped objects identification and mitigation among the workforce.

- Train relevant personnel to identify and mitigate dropped objects processes.

- Secure tools from dropping to lower levels.

- Following Job Safety Environment Assessment (JSEA) guidelines, erect signage and physical barriers to restrict access before work is conducted overhead.

- All rigging risk assessments require consideration of the risks involved in moving equipment at height.

- Review and revise JSEAs for dropped objects potential.

- Introduce regular dropped objects campaigns.

- Schedule regular Hazard Hunts.

- Review handling and securing procedures for tubular components.

- Introduce area ownership, and hold personnel accountable.

- Add secondary retention, and consider safety systems, such as safety nets.

- Inspect personal protective equipment (PPE), for example, safety harness, lanyard and chin straps.

- Inspect all overhead equipment and locations for loose items that may present a hazard during maintenance activities.

13.0 Secondary Retention

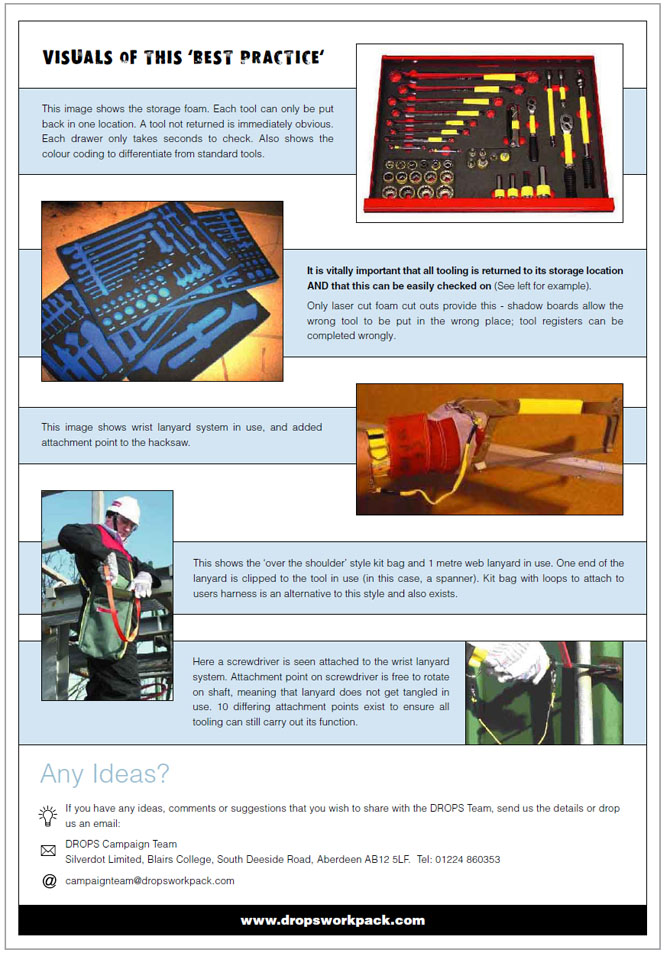

Secondary Securing Devices

Secondary securing devices (SSDs) secure a component at height, if the primary securing method fails. This could be a secondary safety wire (SSW), a safety net or some other engineered method designed for this function. SSD selection should consider the shock loading that may occur if the primary securing method fails. The integrity of the SSD will deteriorate over time and exposure to the elements and needs to be inspected.

Secondary Safety Systems

Secondary safety systems are fail-safe systems incorporated into equipment to ensure integrity of that equipment if the primary safety system fails. For example, a racking arm runs along a beam and is hoisted and lowered with a wire. If the wire fails, an inertia brake prevents the arm from freefalling to the ground.

Secondary safety methods to secure equipment and machinery at height is detailed in the Reliable Securing document published by DROPS.

http://www.dropsonline.org/downloads/DROPS%20Reliable%20Securing%20Revision%203.pdf

14.0 How Can I Personally Prevent Dropped Objects?

- Actively support the dropped objects work group.

- Take responsibility for my actions.

- Look after my colleagues.

- Maintain good housekeeping.

- Stop unsafe activities by using my SWA.

- Make observations and report incidents.

- Review and follow procedures.

- Recognize known hazards, and follow the controls in place.

- Consider dropped objects in all Toolbox Talks.

- Consider dropped objects in all JSEAs.

- Check areas after all work is completed, even if it is permit-controlled.

- Participate in Hazard Hunts.

- Investigate all incidents, including near misses.

- Secure all tools and equipment when working at height.

Lanyard Used for Hand Tools

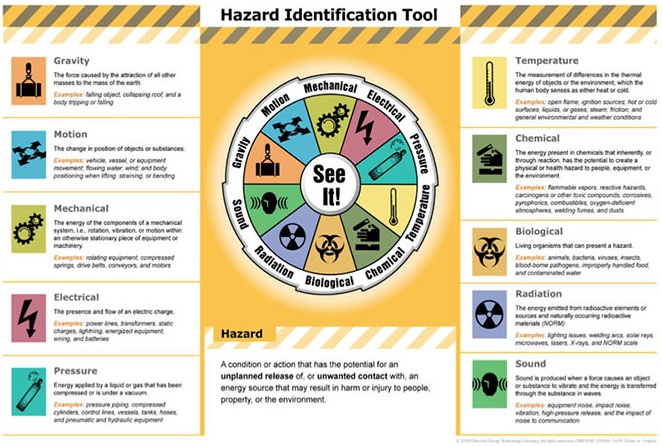

15.0 Chevron Hazard ID Tool: A 360-Degree Approach

No matter where you work, from offshore platforms to onshore refineries, and in offices around the world, hazards are present. Inadequate identification of those hazards can lead to incidents and injuries across our industry.

Chevron has developed a tool that every employee and contractor can use to identify hazards.

A hazard identification tool should:

- Be simple and intuitive to use.

- Provide a platform for continuous and sustained improvement.

- Be culturally neutral (easily understood in as many different cultures and languages as possible).

- Improve the individual worker’s ability to identify hazards.

- Integrate easily with other hazard identification processes (Loss Prevention System [LPS], JSEA, Behavior-Based Safety [BBS] and Permit to Work [PTW]).

A hazard identification tool should NOT be another process to implement.

Hazard ID Tool Purpose:

- Increase awareness of energy sources that present hazards in the workplace.

- For dropped objects, identify and eliminate gravity hazards through a focused Hazard Hunt.

Gravity Hazard Examples:

- Crane loads being lifted

- Falling objects, like tools overhead

- Body trips or falls

Are there any gravity energy conditions at your location that could pose a hazard?

- Areas routinely occupied under potential falling objects, such as overhead loads or tools? Are they identified?

- Areas requiring fall protection PPE?

- Surfaces slippery or wet from weather conditions, water or oil spills?

- Stairs and ramps with loose or missing handrails or damaged tread?

- Surface protrusions or loose surfaces, such as thresholds, cover plates or grating or unsecured floor mats?

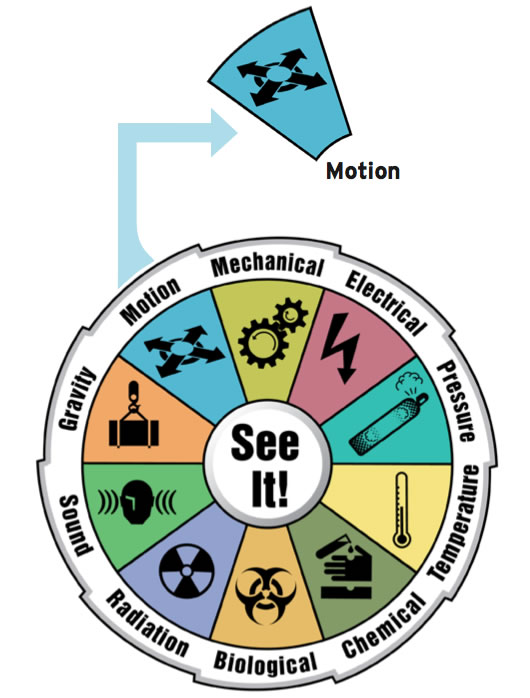

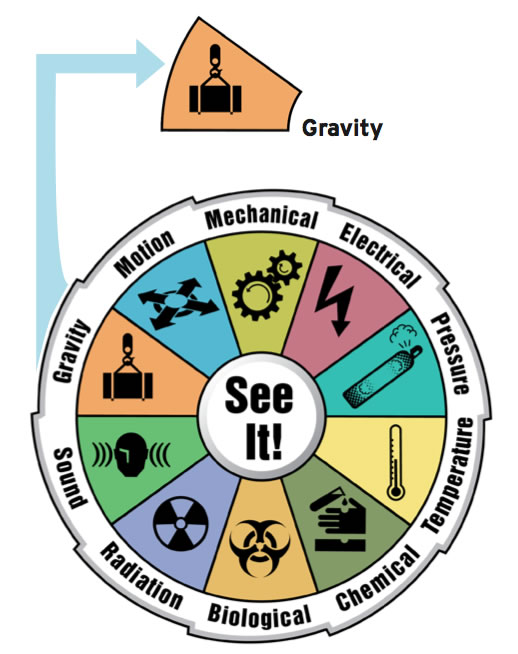

This simple tool is a wheel featuring graphic icons illustrating specific sources of energy that, if not properly handled, could lead to injury or damage to property or the environment.

Energy sources are always present in the environment. Every aspect of our daily life requires the use of energy in one form or another. However, some energy sources can contribute to the dropped object hazard.

Those energy sources are:

Gravity – Enables objects to fall, roofs to collapse and people to trip and fall

Motion – The movement of vehicles, vessels, water, wind or even body movement

Mechanical – Rotating equipment, drive belts, conveyers, motors or compressed springs

Electrical – Including power lines, transformers, static charges, lightning, wiring and batteries

Pressure – Piping, compressed cylinders, tanks, hoses, pneumatic and hydraulic equipment

Temperature – Including ignition sources, hot or cold surfaces, steam, friction and weather

Chemical – Vapors, toxic compounds, combustibles, corrosives, welding fumes and dusts

Biological – Bacteria, viruses, animals, insects, and contaminated food or water

Radiation – Including solar rays, microwaves, X-rays and welding arcs

Sound – Equipment noise, vibration, high-pressure release and even voice communication

16.0 Part of a Complete Safety Package

The Hazard Identification Tool has been designed as either a stand-alone resource or to augment existing processes such as safe work practices, JSEA and PTW.

It is important to understand that this is not a new process to implement. It’s a new tool that can enhance our existing processes by strengthening our ability to recognize hazards.

16.1 Hazard Hunt Using the Hazard ID Tool

Purpose

- Increase awareness of energy sources that present hazards in the workplace.

- Identify and eliminate motion hazards through focused Hazard Hunts.

16.2 What is a Hazard?

A hazard is a condition or action with the potential for an unplanned release of, or unwanted contact with, an energy source that may result in harm or injury to people, property or the environment.

16.3 What to Do Following a Hazard Hunt

- Use SWA to immediately address the imminent hazards.

- Prioritize hazards and identify actions required to eliminate or mitigate.

- Enter maintenance items into database.

- Leaders communicate a summary of the Hazard Hunt by email to their immediate manager.

16.4 Inspections

One of the most important aspects of a good dropped objects program is the ability to inspect all equipment aloft.

- Periodic inspections identify potential hazards.

- Report all non-conformities found in these inspections for correction immediately.

16.5 Temporary Equipment

- Any temporary equipment brought into the site is subjected to the same guidelines as fixed equipment.

- Site management ensures inspection of any third-party equipment before installation.

- To ensure all temporary items are accounted for and have been removed, document the temporary equipment.

- Review all temporary equipment to ensure hazards from dropped or falling objects are identified and monitored.

17.0 Area Ownership

Site management should clearly identify all risk areas and assign risk area ownership.

- Divide the location into areas.

- Assign the areas to an individual or group to check the area as often as the level of risk demands.

- Use checklists for consistency.

- Identify actions for each area of concern.

- Deal with all actions.

- Include any transportable or temporary equipment.

- To make the area safe, use SWA if a dropped object is found.

18.0 Pre-Job Risk Assessment

Complete a pre-job risk assessment such as a JSEA before beginning any job/task, with the following goals in mind:

- Identify any dropped object hazards before starting a job or task and communicate these at a toolbox talk.

- Include discussions on tools and equipment in the JSEA.

- Ensure all personnel are involved in the discussion, understand the associated hazards and implement the mitigation.

- Include the use of a dropped objects checklist.

19.0 References

Here are some examples of some dropped objects posters. Others are available by contacting:

I Chose to Look the Other Way

I could have saved a life that day,

but I chose to look the other way.

It wasn’t that I didn’t care.

I had the time, and I was there.

But I didn’t want to seem a fool,

or argue over a safety rule.

I knew he’d done the job before.

If I called it wrong, he might get sore.

The chances didn’t seem that bad,

I’ve done the same, he knew I had.

So I shook my head and walked on by,

He knew the risks as well as I.

He took a chance, I closed an eye,

and with that act I let him die.

I could have saved a life that day,

but I chose to look the other way.

Now every time I see his wife,

I’ll know I should have saved his life.

That guilt is something I must bear,

but it isn’t something you need to share.

If you see a risk that others take,

That puts their health or life at stake,

The question asked, or the thing you say,

Could help them live another day.

If you see a risk and walk away,

then hope you never have to say,

I could have saved a life that day,

but I chose to look the other way.

Download "Dropped Objects Observations" PDF

Download "Dropped Objects Work Group" PDF

Deepwater Exploration/Projects SBU

1500 Louisiana

Houston, TX