Oregon FACE Report: Construction worker died after falling 20-25 feet from a pump-jack scaffold

-

Fatality Assessment and Control Evaluation (FACE) Program Reports

The National Institute for Occupational Safety and Health’s (NIOSH) Fatality Assessment and Control Evaluation (FACE) Program and State FACE Programs study fatal workplace injuries and prepare reports with recommendations to prevent similar injuries. The following are links to all of the items in this collection:

Documents

- Kentucky FACE Report: Commercial Roofer Falls 30 Feet Through a Skylight While Installing Roof Insulation

- Fatal Occupational Injuries in Massachusetts 2008-2013

- Fatality Assessment & Control Evaluation (FACE) Program

- Washington FACE Report: Glazier Foreman Falls From Stepladder

- Preventing Construction Falls Toolkit

- Hazard Alert: Pedestrian Workers Killed by Forklifts

- Keep Employees in Motor Vehicles Safe

- New York FACE Brochure

- Washington FACE Report: Construction Laborer Falls When Ladder Breaks

- Washington FACE Report: Pipelayer Dies when Trench Wall Collapses

- Washington FACE Report: Carpenter Falls 60 Feet from Bridge Concrete Form

- Washington FACE Report: Foreman and Laborer Fall when Aerial Lift Struck by Vehicle

- Washington FACE Report: Framer Falls 18 Feet while Sheathing Roof

- New York FACE Report: Mechanic Electrocuted when a Mobile Light Tower Contacted Powerline

- New York FACE Report: Two Construction Workers Fatally Crushed when Cement Formwork Collapsed

- Kentucky FACE Report: Construction Laborer Killed in Trench Collapse while Taking Grade Measurements

- California FACE Report: A Heating, Ventilaton and Air Conditioning (HVAC) Contractor Dies when He Falls through a Skylight

- Massachusetts FACE Report: Carpenter Fatally Injured after Falling from an Extension Ladder

- Massachusetts FACE Report: Laborer Fatally Injured after Falling from a Home under Construction

- Oregon FACE Report: Worker Falls When Ladder Slips

- Michigan FACE Information Sheet: Look for Mobile Equipment Blind Spots

- Oregon FACE Report: Collapsed roof trusses kill carpenter foreman

- Washington FACE Report: Roofer Falls 19 Feet from Roof

- Hazard Alert: Plan. Provide. Train. Prevent Fall Injuries & Deaths

- Kentucky FACE Report: 19-Year-Old Construction Laborer Crushed in Trench Collapse While Laying Sewage Pipe

- Kentucky FACE Report: Construction Flagger Struck and Killed in Two-Lane Highway Work Zone

- Kentucky FACE Report:Temporary Electrician Helper Steps into Unguarded Elevator Shaft and Dies

- Fatality Narrative: Roofing Contractor Falls 25 Feet From Church Roof

- Kentucky FACE Report: Construction Siding Subcontractor Installer Killed when Oversized Scaffolding Platform Destabilized and Telescopic Forklift Overturned

- NIOSH FACE Report - Maintenance Worker Struck by Forklift Carriage—Tennessee

- Kentucky Hazard Alert: Roofing and Construction Workers Killed Due to High Winds

- Poster: Secure it to move it!

- Oregon FACE Report: Crane Operator Killed By Falling Steel Beam

- New Jersey FACE Report: Mechanic Dies After Being Crushed Under Electrical Cabinet

- New Jersey FACE Report: Plant Manager Crushed to Death Under Fallen Pile of Steel Beams

- NIOSH FACE Report: Hispanic worker falls from residential roof

- Oregon FACE Report: Construction worker died after falling 20-25 feet from a pump-jack scaffold

- FACE Fact Sheet: Prevent Construction Falls from Roofs, Ladders, and Scaffolds

- Construction Fatality Narrative: Roofer Falls 18 Feet from Wet House Roof

- Construction Worker Killed when Trench Collapsed, Oregon

- A Tree Trimmer is Electrocuted While Trimming a Palm Tree

- A Tree Feller Dies When Struck By a Tree Limb While Felling a Fire-Damaged Tree

- Warehouse Worker Crushed by Forks of Laser Guided Vehicle

Summary Statement

A 46-year-old owner of a small residential siding company died from injuries sustained when he fell approximately 20-25 feet from a pump-jack scaffold platform. The company was a subcontractor hired to install siding on a newly constructed apartment building. The work was being performed using pump-jack scaffolding.

December 2017

SPECIAL ALERT – Falls in construction are a recurring contributing factor to occupational fatalities in Oregon.

SUMMARY

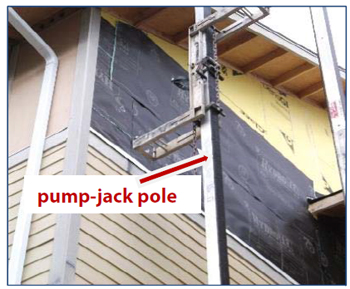

Figure 1. Breezeway, pump jack pole.

A 46-year-old owner of a small residential siding company died from injuries sustained when he fell approximately 20-25 feet from a pump-jack scaffold platform onto a concrete slab. The company was a subcontractor hired to install siding on a newly constructed apartment building. The work was being performed using pump-jack scaffolding. On the day of the incident, the siding subcontractor was installing siding in a breezeway. He and his crew erected the scaffold. However, to work around the concrete stairs and related structures in the breezeway, they used only one pump-jack pole and used the stair landing to support the other end of the scaffold platform. To raise the platform above landing height they placed a stepladder on the landing, and would raise the pumpjack pole on the other side. The siding company owner was working alone at the time of the incident. He apparently was attempting to use a second stepladder placed on top of the scaffold platform to access a high peak above a 3rd floor landing, when he fell to the concrete slab at the bottom of the breezeway. A nearby worker called 911. Emergency responders arrived minutes later and transported the injured siding company owner to a hospital trauma center, where he died the following day.

RECOMMENDATIONS

-

For any project requiring access to a height, employers should evaluate site-specific conditions to determine the most appropriate means of safely accessing the work area.

- General contractors and sub-contractors should require and ensure the use of fall protection appropriate for task and site conditions.

- If obstacles are encountered that may prevent safe or effective use of a conventional method for accessing a height, determine an appropriate alternative method that will enable safe completion of the work. Do not take shortcuts.

- Employers should establish a program that includes provisions for qualified persons to conduct regular and frequent inspections.

- Employers should develop a site-specific safety plan that addresses any particular site conditions that may affect safety or affect use of conventional safety equipment.

- Employers should develop and maintain a safety culture where employees are encouraged to voice concerns about unsafe work conditions.

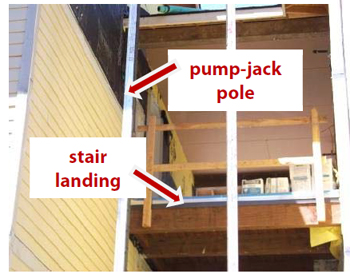

Figure 2. Breezeway, 3rd floor stair landing with

temporary railing.

INTRODUCTION

On July 1, 2015, a 46-year-old construction worker died the day after he sustained injuries from falling approximately 20-25 feet while installing siding on a newly constructed apartment building. OR-FACE received notification of the incident from OR-OSHA; OR-FACE accompanied the investigator during investigation interviews. This report is based on review of investigation documents from OR-OSHA, information obtained during interviews, and follow-up discussions with the OR-OSHA investigator.

The worker who died was the owner of a small siding company. He had three workers assisting him on this project, two of whom had been working for him on various projects for about a year.

The site was a multi-employer construction worksite consisting of four, three-story apartment buildings. The general contractor had hired various sub-contractors, including a siding contractor who in turn hired several siding companies (including the company owned by the deceased) to perform the work over the course of the project. Construction work at the site had begun about nine months prior to the incident. The worker who was fatally injured had been working daily at this site for approximately two months at the time of the incident. Building and roofing construction was complete. Interior work was still underway in various stages of completion, and several specialty trades were working inside the buildings at the time of the incident.

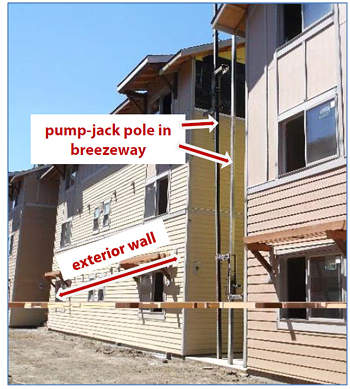

Figure 3. Exterior wall and breezeway.

The incident occurred at the last of the four buildings to be sided and painted. The siding work included applying and attaching building wrap and then installing siding boards. The victim and his crew of three workers had completed siding work on the exterior walls, then began work in the breezeway. Information obtained during interviews indicated that for work on the exterior walls the crew had set up a standard pump-jack scaffolding system. This included a minimum of three pump-jack poles to support scaffold platforms, and personal fall arrest. Specifically, the workers reported tying off to manufactured anchors that they installed on the roof. Given that fall protection equipment was available on site, it is not known why they were not used for the work in the breezeway where the incident occurred. The siding crew indicated there had been some discussion of using a beam under a sub-roof for a tie-off point in a previous breezeway. However, it is not known whether any fall protection system had been used in the previously sided breezeways.

The deceased was an experienced construction worker, although the specific number of years he had worked in the industry is not known. The site general contractor described him as experienced, efficient, and reliable. The siding subcontractor who contracted with him reported that they had a long-term working relationship and had worked together many times.

INVESTIGATION

On the day of the incident, a four-person crew consisting of the siding company owner and three employees set up scaffolding in the breezeway of one of the buildings to install siding on the wall within the breezeway of the last of the four buildings to be sided and painted. They arrived on site around 8:30 or 9:00 AM, their normal start time, and began their work. Reportedly, the concrete stairs, stair landings, and related structures in the breezeway had hindered the abillity to set up a standard scaffold system. This resulted in an incomplete scaffold system set-up around the stairs, with not all of the standard scaffold system components used. Instead they used only one pump-jack pole, supporting one end of the scaffold platform, and used the stair landing to support the other end of the platform. To raise the platform above stair landing height, an 8-foot step ladder was placed on the landing to support that end of the platform and the pump-jack pole was raised on the other side. No fall protection was used during siding work in this breezeway.

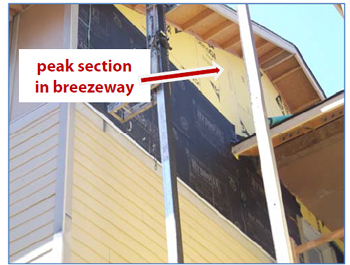

Figure 4. Peak section of breezeway wall.

According to OR-OSHA observations and information obtained through interviews, building wrap and siding had been installed on two lower levels. The crew recalled seeing that the platform was level as the work progressed to the third level. To complete the top section siding required gaining additional height to reach the triangle shaped roof peak area above the third level landing (see Figure 4). It was assumed that to do this, the victim had placed a 6-foot step ladder on top of the scaffold platform. The victim was working alone at the time of the incident, and was not using fall protection. The three siding crew members who been assisting earlier in the day had been asked by a jobsite superintendent to perform a task on another building. Thus, they were not in the immediate vicinity at the time of the incident, nor were any other workers in the immediate vicinity. Therefore, no witnesses directly observed the specific configuration of the scaffold platform or the inferred use of the second step ladder on the platform, nor did anyone see what the victim was doing just prior to falling, or what may have triggered the fall.

Scaffolds and ladders that are not properly installed or secured can tilt or sway and become unstable. In this case, two contributing factors may have affected the stability of the work platform and its ability to withstand side forces. The scaffold platform was not secured on the stair landing and was supported by a step ladder. It is possible that as a result the platform tilted or swayed, causing the victim to lose his balance, or he may have fallen because he lost his footing using the second step ladder while attempting to reach the peak section.

Another contractor, who was working around the corner from the breezeway, said he heard a loud noise, looked up, and saw the siding company owner and a step ladder falling. It was presumed that the falling ladder was the one the victim had attempted to use to reach the peak section, as the other step ladder that had been used to support the scaffold platform remained on the stair landing. This nearby contractor also recalled seeing the scaffold platform tilted up and angled out from the wall, which would be consistent with a fall from the platform.

The victim fell approximately 20-25 feet to the concrete slab. The ladder fell on top of him when he landed on the ground. The nearby contractor instructed another nearby worker to call 911. Emergency responders arrived minutes later and transported the injured siding company owner to a hospital trauma center. He did not regain consciousness and he died at the hospital the following day.

Results of the OR-OSHA investigation found that the site safety plan did not include any specifics pertaining to the work in the breezeways. Weekly safety meetings were conducted, although meeting minutes did not specifically address work in the breezeway.

CAUSE OF DEATH: Blunt force head and neck injuries.

RECOMMENDATIONS/DISCUSSION

- For any project requiring access to a height, employers should evaluate site-specific conditions to determine the most appropriate means of safely accessing the work area.

- When scaffolds are identified as the best method for accessing a height, conduct a preerection assessment to determine all equipment and materials necessary for safe installation and use of the scaffold.

- Alternate methods should be considered when site conditions warrant. For example, for the breezeways on this site, an aerial lift could have been used to access heights that could not be reached using standard pump-jack scaffolding.

- Ensure that all necessary equipment, materials, and supplies are readily available on site.

- Ensure that all employees are adequately trained in erecting all of the types of scaffold systems they may use on a given job site.

- When working at heights, ensure that appropriate fall protection methods are identified, planned for, and properly used.

- General contractors and sub-contractors should require and ensure the use of fall protection appropriate for task and site conditions.

- Personal fall arrest systems, including installing roof anchors for tying off when working at height, were available on site and were used during siding work on performed on the exterior walls.

- Use of a properly installed fall arrest system in the breezeway where the incident occurred likely would have prevented the fatal injury. The employees reported discussing possible tie-off locations for breezeways sided earlier at the project site, but a system was not selected or implemented.

- If obstacles are encountered that may prevent safe or effective use of a conventional method for accessing a height, determine an appropriate alternative method that will enable safe completion of the work. Do not take shortcuts.

- In this case, given that the stairs impeded the ability to install a complete pump-jack scaffold system, an alternative method for more safely accessing the height should have been determined. For example, an aerial lift could have been used to access heights in the breezeway that could not be reached using standard pump-jack scaffolding.

- Do not begin the work unless all applicable scaffold system components are secured in place. For a pump-jack scaffold system, this includes at a minimum:

- Securing poles to the structure with rigid triangular bracing (see example in Figure 5);

- Safe access to scaffolds and scaffold platforms; and

- Use of fall protection, such as personal fall arrest systems or guardrails, when working at heights more than 10 feet above a lower level.

- Do not use ladders to support a scaffold platform, nor should ladders ever be used on top of a scaffold platform.

- Employers should establish a program that includes provisions for qualified persons to conduct regular and frequent inspections.

- Routine construction site inspections should be conducted, and results documented.

- Action items identified during inspections should be discussed among all affected parties, and corrective action should be taken promptly and documented. For multiemployer worksites such as this one, this should be a shared responsibility.

- In this case, installed scaffolds should have been inspected prior to use by a qualified person, and all appropriate safety provisions should have been in place. Siding work should not have continued in the breezeway with the scaffolding configured as it was, and with no fall protection in place.

- Employers should develop a site-specific safety plan that addresses any particular site conditions that may affect safety or affect use of conventional safety equipment.

- In this case, the written safety plan available on site did not address any specific conditions of this job site, for example, siding work in the breezeways.

- Safety meetings also provide an opportunity to discuss site-specific conditions and concerns. In this case, although weekly safety meetings were held, records did not indicate that breezeway work was addressed.

- On multi-employer worksites such as this one, all employers on site share the responsibility for protecting workers from known hazards. Effective inter-employer safety communication practices should be established involving all employers at a given site.

- Employers should develop and maintain a safety culture where employees are encouraged to voice concerns about unsafe work conditions.

- If unsafe conditions, equipment, or actions are observed, this should be communicated to appropriate parties and work should be stopped until corrections are made.

REFERENCES

Oregon Occupational Safety and Health Division (OR-OSHA). 2015. Supported scaffolds: Requirements and best practices for the construction industry. Available online: http://osha.oregon.gov/OSHAPubs/4904.pdf

Occupational Safety and Health Administration. Scaffolding eTool/Supported Scaffolds/Pump Jack. Available online: https://www.osha.gov/SLTC/etools/scaffolding/supported/pumpjack.html

OR-OSHA. Fall protection for construction activities. 2017. Available online: http://osha.oregon.gov/OSHAPubs/2824.pdf

Oregon OSHA. 2016. Fact Sheet: Fall protection trigger heights for the construction industry. Available online: http://osha.oregon.gov/OSHAPubs/factsheets/fs64.pdf

Oregon Occupational Safety and Health Division. 2003. Oregon Administrative Rules Chapter 437, Division 3, Subdivision C, 437-003-0920, 1926.20, General safety and health provisions. Available online: http://osha.oregon.gov/OSHARules/div3/div3C.pdf

FOR MORE INFORMATION

OR-FACE/Oregon Institute of Occupational Health Sciences

Oregon Health & Science University (OHSU)

3181 SW Sam Jackson Park Rd, L606

Portland OR 97239-3098

Phone: (503) 494-2281

Email: orface@ohsu.edu

Website: http://www.ohsu.edu/or-face

OR 2015-12-1

Oregon Fatality Assessment and Control Evaluation (OR-FACE) is a project of the Oregon Institute of Occupational Health Sciences at Oregon Health & Science University (OHSU). OR-FACE is supported by a cooperative agreement with the National Institute for Occupational Safety and Health (NIOSH) (grant #U60OH008472) through the Occupational Public Health Program (OPHP) of the Public Health Division of the Oregon Health Authority. OR–FACE reports are for information, research, or occupational injury control only. Safety and health practices may have changed since the investigation was conducted and the report was completed. Persons needing regulatory compliance information should consult the appropriate regulatory agency.

The following report is the product of our Cooperative State partner and is presented here in its original unedited form from the state. The findings and conclusions in each report are those of the individual Cooperative State partner and do not necessarily reflect the views or policy of the National Institute for Occupational Safety and Health.

OR-FACE supports the prioritization of safety interventions using a hierarchy of safety controls, where top priorities are hazard elimination or substitution, followed by engineering controls, administrative controls (including training and work practices), and personal protective equipment.