Roadway Safety: Instructor Manual

Laborers' Health and Safety Fund of North America

-

Roadway Safety

The following are links to all of the items in this collection:

Documents

- Roadway Safety: Run Overs & Back Overs

- Roadway Safety: Operator Safety

- Roadway Safety: Struck or Crushed

- Roadway Safety: Flagger Safety

- Roadway Safety: Night Work

- Roadway Safety: Excavation

- Roadway Safety: Electrical hazards

- Roadway Safety: Strains and Sprains

- Roadway Safety: Fall Hazards

- Roadway Safety Awareness Program: Trainee Booklet

- Roadway Safety: Instructor Manual

- Roadway Safety: Working outdoors

- Roadway Safety: Noise Hazards

- Roadway Safety: Health Hazards

- Roadway Safety: Emergencies

Summary Statement

A manual that helps a trainer provide information on a variety of roadway hazards, such as electrical, falls, slips and trips and ergonomics. Part of a collection. Click on the 'collection' button to access the other items.

2002

| This document is one in a program produced under an OSHA grant by a consortium of the Laborers' Health and Safety Fund N.A, the International Union of Operating Engineers, the American Road and Transportation Builders Assn, and the National Asphalt Pavement Assn. All of the documents from this set that are on eLCOSH can be found by clicking on Job Site, Heavy construction, and scrolling to the Street & highway heading. Or to download a complete version of the computerized program, go to https://www.workzonesafety.org/. |

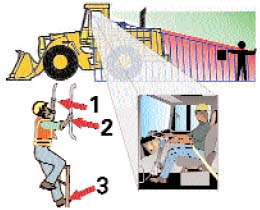

The first rule of operator safety is to unload and operate equipment only if you are qualified. Equipment operation basics include:

- Before starting the equipment, do a complete walkaround inspection.

- Test the back-up alarm and other safety devices.

- Locate and test all controls.

- Know the equipment blind spots and swing radius.

- Use equipment seatbelts. When entering and exiting equipment:

- Use 3 points of contact to prevent falls.

- Look for other moving equipment and vehicles.

- Wipe up all grease and fluids on equipment walking and working surfaces.

|

| Fig. OS-1. Operate equipment only if you are qualified. |

What Are Other Safety Measures?

Stay alert and aware of the hazards. When doing equipment maintenance and repair:

- Report all repair needs to your supervisor.

- Always lock out and tag out equipment that cannot be safely operated.

|

| Fig. OS-2A. Lock out/tag out. |

Notes:

Equipment should receive regular maintenance and repair. Maintenance inspections include hydraulics, brakes, parking brakes, lights, safety belts, etc.

Equipment Inspection Checklist

-Check fluid levels.

-Check tires for air pressure and excessive wear.

-Check for fluid leaks.

-Check safety devices: lights, back up alarms, safety belts.

-Check operator controls: brakes, steering, hydraulic controls, parking brake.

-Have operator manual available for operator.

Checklist should be modified for specific equipment and/or site conditions.

What about job stress? What kind of pressures is the operator under?

General safety tips:

- Use personal protective equipment (PPE) supplied and required by your employer.

- Never use cell phones, AM/FM radios, CD players, or other distractions while operating equipment.

- Safely secure equipment before using employer-provided hand-held cell phones or walkie-talkies.

- Secure unattended equipment.

- Lock-out and tag-out before repair or maintenance. Set the parking brake and chock the wheels. Block dump truck bed.

|

| Fig. OS-2B. Never use cell phones, AM/FM radios, or CD players while operating equipment. Chock the wheels on locked out equipment. |

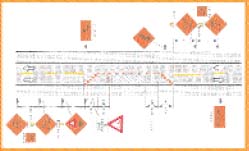

How Can We Be Safe in the Work Zone?

The operator has special responsibilities in the work zone. You must know the job:

- Know the work zone and your position in it.

- Know the internal traffic control plan.

- Know designated routes for public and workers.

- Use designated equipment routes and areas.

- Identify rollover hazards such as unleveled areas, embankments, and unstable soil.

- If cones or barricades must be moved to perform a task, return them to their original positions as soon as the task is completed.

|

| Fig. OS-3. The operator has special responsibilities in the work zone. |

Notes:

AM/FM radios and CD players would just add to a worker's daily noise dose.

When possible, avoid parking equipment on grades. Use level areas.

To secure equipment, lower attachments such as buckets to the ground. Never leave equipment with suspended loads unattended.

How much is visibility a problem for operators? How can it be improved? What about backup video system? Has anyone experienced them?

What is an internal traffic control plan?

What about using spotters?

Always keep other workers in mind. On the work site:

- Know the locations of other workers around you at all times.

- Set up a means of communication with workers around you such as flaggers, grade checkers, and others.

- Never allow other workers to ride on equipment.

- Where possible, provide barriers between workers and equipment.

- Avoid excessive speeds and dangers caused by hills, obstacles, and curves.

|

| Fig. OS-4. Operators have a duty to watch out for other workers. |

Notes:

Ask trainees: How do operators stay in better communication with workers on foot?

Use barriers around concrete breakers attached to heavy equipment to prevent injury or damage from flying concrete.

Suggest adding barricades around bike paths near the work zone.

Rope off or barricade cranes and backhoes to prevent injury from swinging machinery.

Back to Contents