Roadway Safety: Instructor Manual

Laborers' Health and Safety Fund of North America

-

Roadway Safety

The following are links to all of the items in this collection:

Documents

- Roadway Safety: Run Overs & Back Overs

- Roadway Safety: Operator Safety

- Roadway Safety: Struck or Crushed

- Roadway Safety: Flagger Safety

- Roadway Safety: Night Work

- Roadway Safety: Excavation

- Roadway Safety: Electrical hazards

- Roadway Safety: Strains and Sprains

- Roadway Safety: Fall Hazards

- Roadway Safety Awareness Program: Trainee Booklet

- Roadway Safety: Instructor Manual

- Roadway Safety: Working outdoors

- Roadway Safety: Noise Hazards

- Roadway Safety: Health Hazards

- Roadway Safety: Emergencies

Summary Statement

A manual that helps a trainer provide information on a variety of roadway hazards, such as electrical, falls, slips and trips and ergonomics. Part of a collection. Click on the 'collection' button to access the other items.

2002

| This document is one in a program produced under an OSHA grant by a consortium of the Laborers' Health and Safety Fund N.A, the International Union of Operating Engineers, the American Road and Transportation Builders Assn, and the National Asphalt Pavement Assn. All of the documents from this set that are on eLCOSH can be found by clicking on Job Site, Heavy construction, and scrolling to the Street & highway heading. Or to download a complete version of the computerized program, go to https://www.workzonesafety.org/. |

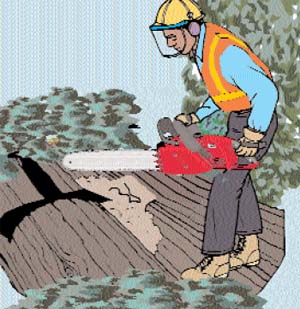

Tools and materials are two major hazards:

- Use point of operation guarding on portable hand tools.

- Use chain saw safety program.

- Assess and use PPE. To avoid being struck or crushed by materials:

- Keep workers out of lifting areas, from beneath loads.

- Use safe hoisting and rigging practices.

- Use safe methods for rigging, hoisting, and setting steel plates, jersey barriers, manhole frames, and manhole covers.

- Use PPE — hard hats, footwear, eye protection.

|

| Fig. SC-1B. Keep workers from beneath loads. |

|

| Fig. SC-1A. Tools and materials are two major hazards that can strike or crush workers. |

Notes:

Ask trainees: What percentage of the injuries are struck/crushed? (About 17% of all serious injuries in highway work involve workers being struck by things other than equipment. Another 3% are workers being crushed between objects. Together, these account for more than one-fifth of all serious injuries in highway work.)

What type of injuries do they get (fractures)?

Ask trainees: What kinds of things could you get hit by on our site? (Take examples from trainees.) How can we avoid this problem?

Operators should never swing loads over workers, traffic, or pedestrians.

Trees and equipment maintenance are hazards. To avoid being struck by trees:

- Restrict worker access during felling, trimming, loading.

- Falling Object Protective Structures (FOPS) on equipment.

- Use safe hoisting, rigging for logs and limbs.

- Lockout/tagout/hazardous energy control during maintenance, repair, cleaning, and inspection.

|

| Fig. SC-2B. Lock out and tag out during maintenance. |

|

| Fig. SC-2A. Trees and equipment maintenance are hazards that can crush or strike workers. |

Notes:

Ask trainees: What are some other items that we haven't discussed that can strike or crush workers in road work? (Answers include falling objects on bridge work, flying materials like plywood caught in the wind, rocks flying out from tires.)

Back to Contents