Concrete Finisher Electrocuted When Bull Float Contacted an Energized Power Line

-

Fatality Assessment and Control Evaluation (FACE) Program Reports

The National Institute for Occupational Safety and Health’s (NIOSH) Fatality Assessment and Control Evaluation (FACE) Program and State FACE Programs study fatal workplace injuries and prepare reports with recommendations to prevent similar injuries. The following are links to all of the items in this collection:

Documents

- Kentucky FACE Report: Commercial Roofer Falls 30 Feet Through a Skylight While Installing Roof Insulation

- Fatal Occupational Injuries in Massachusetts 2008-2013

- Fatality Assessment & Control Evaluation (FACE) Program

- Washington FACE Report: Glazier Foreman Falls From Stepladder

- Preventing Construction Falls Toolkit

- Hazard Alert: Pedestrian Workers Killed by Forklifts

- Keep Employees in Motor Vehicles Safe

- New York FACE Brochure

- Washington FACE Report: Construction Laborer Falls When Ladder Breaks

- Washington FACE Report: Pipelayer Dies when Trench Wall Collapses

- Washington FACE Report: Carpenter Falls 60 Feet from Bridge Concrete Form

- Washington FACE Report: Foreman and Laborer Fall when Aerial Lift Struck by Vehicle

- Washington FACE Report: Framer Falls 18 Feet while Sheathing Roof

- New York FACE Report: Mechanic Electrocuted when a Mobile Light Tower Contacted Powerline

- New York FACE Report: Two Construction Workers Fatally Crushed when Cement Formwork Collapsed

- Kentucky FACE Report: Construction Laborer Killed in Trench Collapse while Taking Grade Measurements

- California FACE Report: A Heating, Ventilaton and Air Conditioning (HVAC) Contractor Dies when He Falls through a Skylight

- Massachusetts FACE Report: Carpenter Fatally Injured after Falling from an Extension Ladder

- Massachusetts FACE Report: Laborer Fatally Injured after Falling from a Home under Construction

- Oregon FACE Report: Worker Falls When Ladder Slips

- Michigan FACE Information Sheet: Look for Mobile Equipment Blind Spots

- Oregon FACE Report: Collapsed roof trusses kill carpenter foreman

- Washington FACE Report: Roofer Falls 19 Feet from Roof

- Hazard Alert: Plan. Provide. Train. Prevent Fall Injuries & Deaths

- Kentucky FACE Report: 19-Year-Old Construction Laborer Crushed in Trench Collapse While Laying Sewage Pipe

- Kentucky FACE Report: Construction Flagger Struck and Killed in Two-Lane Highway Work Zone

- Kentucky FACE Report:Temporary Electrician Helper Steps into Unguarded Elevator Shaft and Dies

- Fatality Narrative: Roofing Contractor Falls 25 Feet From Church Roof

- Kentucky FACE Report: Construction Siding Subcontractor Installer Killed when Oversized Scaffolding Platform Destabilized and Telescopic Forklift Overturned

- NIOSH FACE Report - Maintenance Worker Struck by Forklift Carriage—Tennessee

- Kentucky Hazard Alert: Roofing and Construction Workers Killed Due to High Winds

- Poster: Secure it to move it!

- Oregon FACE Report: Crane Operator Killed By Falling Steel Beam

- New Jersey FACE Report: Mechanic Dies After Being Crushed Under Electrical Cabinet

- New Jersey FACE Report: Plant Manager Crushed to Death Under Fallen Pile of Steel Beams

- NIOSH FACE Report: Hispanic worker falls from residential roof

- Oregon FACE Report: Construction worker died after falling 20-25 feet from a pump-jack scaffold

- FACE Fact Sheet: Prevent Construction Falls from Roofs, Ladders, and Scaffolds

- Construction Fatality Narrative: Roofer Falls 18 Feet from Wet House Roof

- Construction Worker Killed when Trench Collapsed, Oregon

- A Tree Trimmer is Electrocuted While Trimming a Palm Tree

- A Tree Feller Dies When Struck By a Tree Limb While Felling a Fire-Damaged Tree

- Concrete Finisher Electrocuted When Bull Float Contacted an Energized Power Line

- Warehouse Worker Crushed by Forks of Laser Guided Vehicle

Summary Statement

In the summer of 2016, a male concrete finisher in his 30s was electrocuted when the handle of the 29-foot-long metal bull float he was using contacted an energized 7,200 volt power line. The decedent and his coworkers were performing concrete finishing work for a residential driveway. The decedent was facing south, finishing the concrete driveway and the power lines were at his back (north) when the incident occurred. A line of brush was approximately 8 feet away from him under the power lines, which may have required him to elevate the bull float handle rather than pull it in a more horizontal position. The decedent was wearing non-electrical rated rubber boots over his leather work boots, vinyl work gloves, hard hat and safety glasses. When the bull float handle contacted the overhead line, the decedent fell forward, letting go of the pole. The utility company measured the height of the two overhead lines after the incident. The bottom neutral line was 17 feet high and the 7,200-volt primary line was 23-feet high vertically and 24 feet from the edge of the concrete forms. There were two visible impact burn points on the wire. One was a 1.5-2-inch width of the bull float pole and the second contact was approximately 2.3-3.0 feet long where the pole may have slid along the wire. Emergency response was called and the decedent was transported to a local hospital where he died.

MIFACE identified the following key and possibly contributing factors:

- Unfamiliarity with residential jobsites and associated hazards relating to nearby, above- round power lines.

- Failure to identify and assess power lines as hazards and make appropriate recommendations to employees regarding work practices and equipment.

- Use of conductive bull float handles.

April 2019

Recommendations

- Conduct a jobsite survey and hazard assessment to identify all potential hazards, including those associated with overhead power lines.

- Institute a hazard awareness program in which employees are educated about potential hazards as well as any specific hazards noted during the jobsite survey.

- When working near overhead power lines, ensure that a minimum of 10 feet of space is maintained between the equipment and the power line.

- Contact the power company to alert them about the work being performed near power lines.

- Use bull float handles that are non-conductive and/or insulated.

Background

In the fall of 2016, a male concrete finisher in his 30s was electrocuted when the metal handle of his 29-foot-long metal bull float he was using to smooth concrete contacted an energized 7,200 volt power line overhead. MIFACE researchers became aware of the fatality via the MIOSHA 24-hour ASAP reporting system. The owner, who was the father of the decedent, agreed to participate in the research after being contacted by MIFACE. The MIFACE researcher visited the work site and, with the permission of the family member, the MIFACE researcher took photographs of the incident site. During the writing of this report, the death certificate, medical examiner and police reports, and the MIOSHA compliance file were reviewed. The pictures used in this report are courtesy of MIOSHA compliance file.

The decedent was a foreman and concrete finisher for a concrete contractor. He was one of 20 employees at the time of the incident. The company had been operating for 40 years, and the decedent had worked full-time for this company for 15 years total, and the past 5 years consecutively following a 5-year hiatus working for another contractor. The company normally performed work such as pouring foundations for larger commercial or industrial projects, but was pouring concrete for a driveway in a residential lot neighboring the company’s location during the incident. The decedent normally worked 10-12 hour shifts.

The company had in place a written accident prevention plan aiming to address site-specific hazards. Additionally, although the company regularly held toolbox talks regarding safety issues, the owner didn’t believe the topic of overhead power lines had ever been covered, since their normal work involved foundation-pouring projects, where the sites were in wide-open areas and power lines had either not been installed or were located underground. The decedent had received formal safety training during his 5 years at another company, although it is unknown if this training included overhead power line safety.

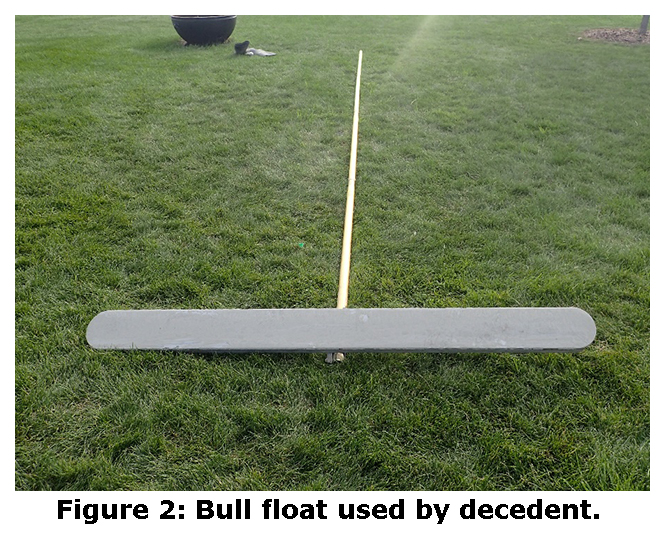

The company had been using bull floats with aluminum handles for many years to smooth the concrete after leveling. These handles were preferred for their light weight, low cost, and durability. The business owner indicated during the interview that he has since switched to using fiberglass handles, which are slightly heavier and approximately the same cost but are markedly less conductive.

Company Remediation

Since the incident, the company has conducted employee training specifically regarding hazard assessment and identification for overhead power lines. Additionally, following the incident and subsequent MIOSHA investigation, the owner in conjunction with MIOSHA and the power company held a training seminar for other contractors to raise awareness about the hazards presented by overhead power lines and ways to prevent similar incidents from happening. A representative of a manufacturer of fiberglass handles was also present at the event, in an effort to encourage and facilitate the use of non-conductive handles by other contractors.

MIOSHA Citations

MIOSHA Construction Safety and Health Division issued the following Serious citations to the company at the conclusion of its investigation:

SERIOUS: GENERAL RULES, CS PART 1, RULE 408.40115(5): Employees not specifically covered by Construction Safety Standard Part 16 Power Transmission and Distribution, Construction Safety Standard Part 17 Electrical Installations, or Construction Safety Standard Part 30 Telecommunications, as referenced in R 408.40105, shall not be allowed by the employer to work or be closer to energized electrical line, gear, or equipment exposed to contact than the minimum clearance.

- Employee using equipment closer than allowable distance to 7200-volt overhead power line.

SERIOUS: CONCRETE CONSTRUCTION, CS PART 25, RULE 408.42520(3): The handle on a bull float that is used where it may contact an energized electrical conductor shall be constructed of non-conductive material or shall be insulated with a non-conductive sheath that has electrical and mechanical characteristics which provide the equivalent protection of a handle constructed of non-conductive material.

- An employee was engaged in concrete finishing work, when the 29-foot aluminum handle of his bull float came in contact with a 7200-volt overhead power line.

Investigation

The company was pouring an approximately 30-35 cubic yard concrete slab for a residential driveway, with the garage of the house facing north and the driveway extending from the front of the garage east down a hill to the street. On the north edge of the driveway was a line of trees, and then a small gulley that deepened as the hill rose to the west, separating the property from the neighboring lot to the north (where the concrete company was located, on a hill across the gully). The power line extended east-west along this property line, with the poles extending into the gulley. At the bottom of the hill, along the street, the neutral and 7,200 V energized power lines ran on opposite sides of the pole, but switched to being paired vertically (with the neutral line on the bottom, and the energized line on top) by the time they reached the pole near the northwest corner of the driveway. The company had backed a cement truck up near the garage, and they had begun pouring at the face of the garage that morning from south to north.

The decedent arrived at the site as one of 10-12 workers present that day at 7:00 AM. The area to be poured was delineated with pieces of lumber, which were in turn held in place with metal pins driven into the ground. Concrete pouring commenced around 8:00 AM. The decedent was reported to have used a bull float attached to four or five 6-ft aluminum handles connected in sequence, which gave him approximately 24-30 feet of reach. This was corroborated by the MIOSHA investigation that stated that the bull float had 29 total feet of reach. The handles were connected to the float via a mechanism that altered the angle of the handle-float joint via the axial rotation of the handles, which allowed for the float to maintain level contact with the concrete along the length of its use without progressively elevating the handle as the float was drawn nearer (Figure 2).

As the slab being poured was approximately 33 feet wide, the decedent had to walk around the edge of the slab in order to reach the entirety of the concrete being poured. The decedent began the process of smoothing the poured concrete on a patch of lawn directly adjacent to the garage, in the southwest corner of the driveway. From there, he moved north along the western edge of the driveway repeating the process, before he relocated along the northern edge of the driveway around 9:30 AM (Figure 1, photo facing north).

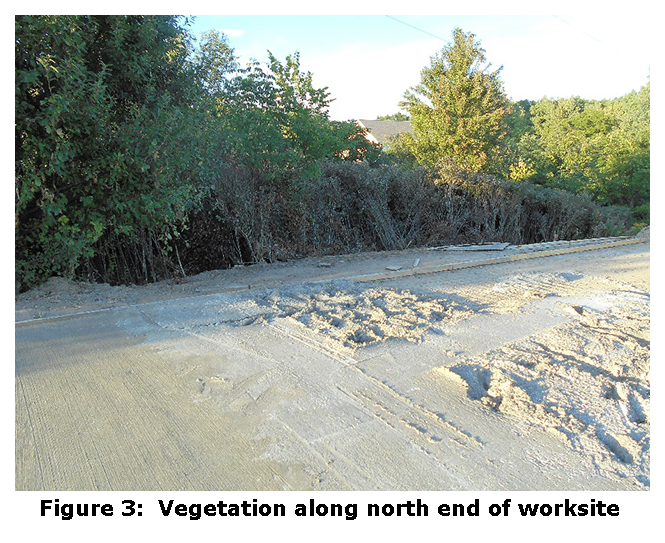

Once along the northern edge of the driveway, the decedent was unable to hold or use the entirety of the bull float handles horizontally, as the vegetation along the top of the gully began approximately 8 feet behind him (Figure 3). This may have required him to elevate the 29-foot handle more than usual. Once elevated, the handle made contact with the energized power line.

Witnesses say they heard a popping noise and saw the decedent’s body give way, and that he began to lower the float handle. At this point the metal float head contacted steel pins holding the wooden form around the pouring site, grounding the circuit and further electrocuting the decedent and causing the fuse for the power line to blow.

The power lines had been noted during an initial site assessment the previous week he had noted the power lines. Similarly, the MIOSHA investigation found that in the days leading up to the incident some work had been done to prepare the area underneath and around the overhead line, and that workers had made note of the pole and lines. However, the owner stated that the lines and their hazards were not discussed with the work crew in the planning of the project. During the MIOSHA investigation, one member of the work crew noted that previous power line hazards had been discussed informally when they were noticed. It is unknown whether the decedent or other present during the incident were aware of the power lines or the hazard they represented.

While the owner was aware of the availability of non-conductive handles and had used them in the past, he stated that they did not use them regularly because of their increased weight compared to the aluminum handles, that non-conductive handles were less durable, and the holes through which the non-conductive handles screwed into the mechanism on the float that enables the angle of the float to be changed via the rotation of the handle would widen with use, requiring a greater rotation for a given change in angle and decreasing the mechanism’s efficiency. Consequently, each of the handles connected to the float used by the decedent were composed of aluminum.

According to the police report, the energy company took measurements of the power lines after the incident, and found the bottom neutral line to be 17 feet above grade, while the top energized line was 23 feet above grade and 24 feet from the edge of the work site at an angle (at about 8 feet away horizontally). There were two burn points on the energized line, one was 1.5-2 inches wide (approximately the width of the handle), and the other was 2.3-3 feet long, suggesting the handle slid along the power line. The owner suggested that the fact that the pole supporting the power lines was situated in the gulley further contributed to the death since the vertical distance to the power lines from the driveway was not the full height of the pole.

The decedent was reported to not be wearing any personal protective equipment (PPE) at the time of the incident, although the police report noted that he had been wearing work boots and black rubber concrete boots. The MIOHSA report stated that the decedent was wearing eye protection and a hard hat. None of this PPE would have provided protection from an electrocution.

Once the decedent had been electrocuted, one coworker began administering CPR, while another ran to get the owner from the company’s property to the north. Emergency response was called, and the decedent died later at a local hospital.

Cause of Death

The cause of death as listed by the medical examiner on the death certificate was electrocution. The victim was found to have ibuprofen, nicotine, and caffeine in his blood; all other toxicological tests were negative.

Recommendations/Discussion

Conduct a jobsite survey and hazard assessment to identify all potential hazards, including those associated with overhead power lines.

Both the MIFACE interviews as well as the MIOSHA investigation found that the power lines were noted during job planning and preparation, with space below the lines being cleared ahead of the day of the incident, although it did not appear that the hazards associated with the power lines were communicated to the workers present on the day of the death. Prior to the start of a project, employers should conduct a worksite inspection, note any potential hazards to employees and take steps to plan and implement appropriate controls to minimize the risks posed by the project. The use of a hazard assessment checklist or other standardized form can help remind those conducting the survey of potential hazards to look for, even if they are rare or unusual for the typical work performed by the contractors. Furthermore, the presence of any noted hazards should be communicated to the contractors working at the site. In this case, such an assessment could have noted both the presence of the power lines themselves, their height in relation to the bull float handles to be used, and the nearby tree line that would’ve complicated ideal use of the float and the maintenance of a safe distance from the lines.

Institute a hazard awareness program to educate employees about the potential and specific hazards noted during the jobsite survey and how to minimize exposure to these hazards.

Regular training for employees in hazard awareness and identification encourages employees to remain vigilant regarding worksite hazards to themselves and their coworkers. Additionally, specific discussions before the start of a project, such as toolbox talks, regarding any hazards identified for the particular worksite and their pertinent controls, in conjunction with warning signage, ensures that employees are aware of these hazards and equipped to control and mitigate them. No such communication regarding the power lines, or the vegetation that would require elevating the float handle near the lines, was given prior to the start of the project on the day of the incident. MIFACE recommends site-specific reminders of electrocution hazards during toolbox talks preceding any project when energized overhead power lines have been identified in the site survey, as well as the controls (including work practices and equipment) to be used to eliminate the hazards at the worksite. Additionally, it is recommended to either place warning signs at the worksite in the vicinity of the power lines to continually remind workers of the hazards, or to restrict entry to the vicinity.

When working near overhead power lines, ensure that a minimum of 10 feet of space is maintained between the equipment and the power line.

MIOSHA Construction Safety Standards, Part 1 Rule 40115 dictates that workers may not be within 10 feet of any energized electrical lines, gear, or equipment for voltages up to 50 kV. The absence of training focusing on power lines likely meant that the employees at the worksite were not aware of this standard and did not organize the work site to ensure its implementation throughout the project. The bull float with a 29 foot handle that was used on the north side of the worksite underneath the lines against a line of vegetation required the elevation of the handle thus and likely necessitated violating the 10 feet of clearance. Other work practices, such as the use of a longer handle from other sides of the driveway might have been implemented if this standard was being observed. As discussed above, signage or an area restriction can be used to keep workers aware of the extent of the 10-foot clearance area.

Contact the power company to alert them about the work being performed near power lines.

Contacting the power company before beginning a project can provide information regarding whether lines are energized, the heights of the lines, and instructions for safe work practices. A representative from the power company may be able to come to the work site to perform a project-specific assessment and make further safety recommendations. If appropriate clearance around the energized line cannot be guaranteed due to constraints of the work site and project, contact the power company to request that they be de-energized for the duration of the project.

Use bull float handles that are non-conductive and/or insulated.

MIOSHA Construction Safety Standard, Part 25 Rule 2520 states that the handle of a bull float being used near an energized electrical conductor must be either constructed of nonconductive material or insulated in a nonconductive sheath. These requirements aside, according to the employer he and many other contractors are aware of the availability of such nonconductive handles, but have frequently chosen to continue using aluminum handles because of weight and durability concerns. However, these concerns can be mitigated at least partially by restricting the use of non-aluminum handles to only those work sites where electrical hazards have been identified during the worksite hazard assessment, prolonging the lifespan of the non-aluminum handles. Worker rotation can also be used if the increased weight of non-conductive handles leads to more frequent exhaustion on the part of the worker using the float. Since the incident, the employer has purchased multiple fiberglass handles and has instructed employees to use them when working near overhead power lines.

Resources

MIOSHA standards cited in this report may be found at and downloaded from the MIOSHA, Michigan Department of Licensing and Regulatory Affairs (LARA) website at: http://www.michigan.gov/lara/0,4601,7-154-11407_15368---,00.html. MIOSHA standards are available by writing to: Michigan Department of Licensing and Regulatory Affairs (LARA), MIOSHA Regulatory Services Section, Stevens T. Mason Building, 530 W. Allegan Street, Lansing, Michigan 48933, calling (517) 284-7740, or by FAX (517) 284-7735.

- MIOSHA Construction Safety Standard, Part 1. General Rules: http://www.michigan.gov/documents/lara/lara_miosha_cs_part_1_426600_7.pdf

- MIOSHA Construction Safety Standard, Part 25. Concrete Construction: http://www.michigan.gov/documents/CIS_WSH_part25_35542_7.pdf

MIFACE Investigation Report #16MI104

KEY WORDS: Electrocution, Power Lines, Bull Float, Concrete, Construction

MIFACE (Michigan Fatality Assessment and Control Evaluation), Michigan State University (MSU) Occupational & Environmental Medicine, 909 Fee Road, 117 West Fee Hall, East Lansing, Michigan 48824-1315; http://www.oem.msu.edu. This information is for educational purposes only. This MIFACE report becomes public property upon publication and may be printed verbatim with credit to MSU. Reprinting cannot be used to endorse or advertise a commercial product or company. All rights reserved. MSU is an affirmative-action, equal opportunity employer.