New Jersey FACE Report: Mechanic Dies After Being Crushed Under Electrical Cabinet

-

Fatality Assessment and Control Evaluation (FACE) Program Reports

The National Institute for Occupational Safety and Health’s (NIOSH) Fatality Assessment and Control Evaluation (FACE) Program and State FACE Programs study fatal workplace injuries and prepare reports with recommendations to prevent similar injuries. The following are links to all of the items in this collection:

Documents

- Kentucky FACE Report: Commercial Roofer Falls 30 Feet Through a Skylight While Installing Roof Insulation

- Fatal Occupational Injuries in Massachusetts 2008-2013

- Fatality Assessment & Control Evaluation (FACE) Program

- Washington FACE Report: Glazier Foreman Falls From Stepladder

- Preventing Construction Falls Toolkit

- Hazard Alert: Pedestrian Workers Killed by Forklifts

- Keep Employees in Motor Vehicles Safe

- New York FACE Brochure

- Washington FACE Report: Construction Laborer Falls When Ladder Breaks

- Washington FACE Report: Pipelayer Dies when Trench Wall Collapses

- Washington FACE Report: Carpenter Falls 60 Feet from Bridge Concrete Form

- Washington FACE Report: Foreman and Laborer Fall when Aerial Lift Struck by Vehicle

- Washington FACE Report: Framer Falls 18 Feet while Sheathing Roof

- New York FACE Report: Mechanic Electrocuted when a Mobile Light Tower Contacted Powerline

- New York FACE Report: Two Construction Workers Fatally Crushed when Cement Formwork Collapsed

- Kentucky FACE Report: Construction Laborer Killed in Trench Collapse while Taking Grade Measurements

- California FACE Report: A Heating, Ventilaton and Air Conditioning (HVAC) Contractor Dies when He Falls through a Skylight

- Massachusetts FACE Report: Carpenter Fatally Injured after Falling from an Extension Ladder

- Massachusetts FACE Report: Laborer Fatally Injured after Falling from a Home under Construction

- Oregon FACE Report: Worker Falls When Ladder Slips

- Michigan FACE Information Sheet: Look for Mobile Equipment Blind Spots

- Oregon FACE Report: Collapsed roof trusses kill carpenter foreman

- Washington FACE Report: Roofer Falls 19 Feet from Roof

- Hazard Alert: Plan. Provide. Train. Prevent Fall Injuries & Deaths

- Kentucky FACE Report: 19-Year-Old Construction Laborer Crushed in Trench Collapse While Laying Sewage Pipe

- Kentucky FACE Report: Construction Flagger Struck and Killed in Two-Lane Highway Work Zone

- Kentucky FACE Report:Temporary Electrician Helper Steps into Unguarded Elevator Shaft and Dies

- Fatality Narrative: Roofing Contractor Falls 25 Feet From Church Roof

- Kentucky FACE Report: Construction Siding Subcontractor Installer Killed when Oversized Scaffolding Platform Destabilized and Telescopic Forklift Overturned

- NIOSH FACE Report - Maintenance Worker Struck by Forklift Carriage—Tennessee

- Kentucky Hazard Alert: Roofing and Construction Workers Killed Due to High Winds

- Poster: Secure it to move it!

- Oregon FACE Report: Crane Operator Killed By Falling Steel Beam

- New Jersey FACE Report: Mechanic Dies After Being Crushed Under Electrical Cabinet

- New Jersey FACE Report: Plant Manager Crushed to Death Under Fallen Pile of Steel Beams

- NIOSH FACE Report: Hispanic worker falls from residential roof

- Oregon FACE Report: Construction worker died after falling 20-25 feet from a pump-jack scaffold

- FACE Fact Sheet: Prevent Construction Falls from Roofs, Ladders, and Scaffolds

- Construction Fatality Narrative: Roofer Falls 18 Feet from Wet House Roof

- Construction Worker Killed when Trench Collapsed, Oregon

- A Tree Trimmer is Electrocuted While Trimming a Palm Tree

- A Tree Feller Dies When Struck By a Tree Limb While Felling a Fire-Damaged Tree

- Warehouse Worker Crushed by Forks of Laser Guided Vehicle

Summary Statement

A 62-year-old male mechanic died after being crushed by a 993.5-pound electrical cabinet he was working on tipped over. The incident occurred in a decommissioned equipment storage area of a frozen food manufacturing facility. On the day of the incident, the victim was removing salvageable equipment from a nonworking electrical cabinet, when it tipped over and crushed him between the floor and the cabinet. The victim died less than an hour later from compressional asphyxia combined with chest and cervical spine injuries.

April 25, 2016

Figure 1. Front view of electrical

cabinet upright.

SUMMARY

A 62-year-old male mechanic died after being crushed by a 993.5-pound electrical cabinet he was working on tipped over. The incident occurred in a decommissioned equipment storage area of a frozen food manufacturing facility. On the day of the incident, the victim was removing salvageable equipment from a nonworking electrical cabinet, when it tipped over and crushed him between the floor and the cabinet. The victim died less than an hour later from compressional asphyxia combined with chest and cervical spine injuries.

Contributing Factors:

- Rusted/deteriorated leg supports

- Unit not anchored to wall

NJ FACE investigators recommend that these safety guidelines be followed to prevent similar incidents:

- A safety and health plan based on a job hazard analysis should be developed by the employer and followed where workers are assigned tasks.

- Prior to working on any object with a potential tipping hazard, proper support and structural integrity should be ensured.

- Any object with a potential tipping hazard should be adequately anchored to a permanently fixed point, such as wall or column.

Introduction

In winter 2015, NJ FACE staff was notified of the death of a 62-year-old male mechanic who was killed after a 993.5-pound nonworking electrical cabinet he was working on tipped over. The incident occurred in a frozen food manufacturing plant in northern NJ. The victim had worked for the company for approximately 25 years.

An NJ FACE investigator contacted the OSHA Area Office and conducted a concurrent investigation. Additional information was obtained from the medical examiner’s report, death certificate, and police report.

INVESTIGATION

The incident site was the decommissioned equipment storage area of a frozen food manufacturing plant located in northern NJ. The employer was a large food manufacturer with multiple locations; this specific plant’s distribution was mostly the northeastern United States. Seventy-five permanent workers were employed at this location (10,000 employees world-wide). Food was prepared on site, frozen, boxed, and then shipped.

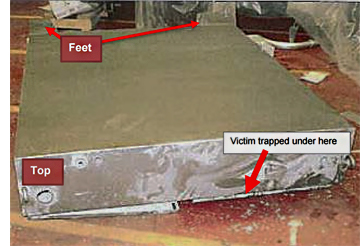

Figure 2. Incident scene; cabinet fell forward

crushing the victim underneath.

On the day of the incident, the victim arrived at 3:00 am for his shift. In addition to his normal duties as a mechanic, he was tasked with removing any salvageable parts from a large electrical cabinet. The cabinet measured 61-inches-wide, by 87-inches- high, by 12.5-inches-deep, and weighed 993.5 pounds (see Figure 1). The cabinet was located in a section of the plant reserved for storage of decommissioned equipment. The company had been recently sold, and the new owner decided to scrap all the equipment in this area. Employees were assigned to remove working parts to be used as possible replacement/spare parts for equipment still in service.

Near the end of his shift, the victim was working alone removing electrical circuit boards and other components from the cabinet. To reach some of the higher components inside the cabinet, he had to stand on the bottom shelf. Although there were no witnesses, it is believed (based on his position underneath the cabinet) that while he was standing on the bottom shelf and removing components, the cabinet tipped over and trapped him underneath as it crashed to the ground (Figure 2). The plant safety manager heard the noise of the crash and immediately ran over and, unsuccessfully, tried lifting the cabinet off the victim. He then radioed for help and five employees rushed to the scene. One employee called 9-1-1 while another drove a forklift over to help free the victim. The forks were placed under the electrical cabinet, two workers and the safety manger stabilized the cabinet on the forks while the other 2 worker pulled the victim free. Two of the workers immediately began to administer CPR. Police and EMS arrived and the victim was transported to the hospital, where he was pronounced dead on arrival due to compressional asphyxia along with severe chest and spine injuries

RECOMMENDATIONS/DISCUSSION

Recommendation #1: A safety and health plan based on a job hazard analysis should be developed by the employer and followed where workers are assigned tasks.

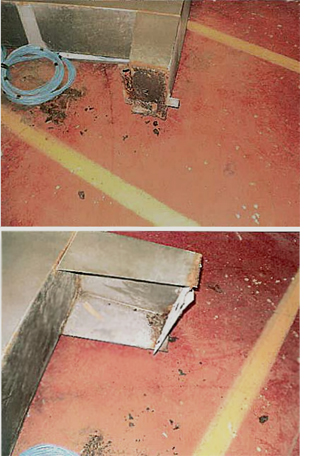

Figure 3. Views of cabinet foot at incident scene.

Recommendation # 2: Prior to working on any object with a potential tipping hazard, proper support and structural integrity should be ensured.

Discussion: As per 29 CFR 1910.176(b) (Materials Handling and Storage), storage of material should not create a hazard, and should be stable against sliding or collapse.2 As noted in Recommendation #1 above, the metal feet that supported the cabinet were in poor condition. It is believed that when the victim was standing on the cabinet, the feet collapsed causing the unit to tip over. NJ FACE recommends that all structural components be inspected prior to starting work, especially if there is a potential tipping hazard.

Recommendation # 3: Any object with a potential tipping hazard should be adequately anchored to a permanently fixed point, such as wall or column.

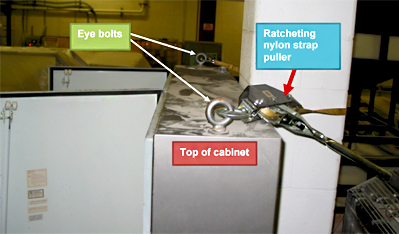

Discussion: 29 CFR 1910.176(b) also notes that items should be secured against collapse. Any free standing object with the potential for tipping over should be anchored or attached to a wall or structural column. In this case, after the incident the employer secured the cabinet to a concrete column using a nylon strap attached to eye bolts affixed to the top of the cabinet (Figure 4). An in-line ratcheting nylon strap puller was used to tighten and maintain the tension on strap.

Figure 4. Electrical cabinet anchored to concrete column using nylon strap.

APPENDIX

RECOMMENDED RESOURCES

It is essential that employers obtain accurate information on health, safety, and applicable OSHA standards. NJ FACE recommends the following sources of information which can help both employers and employees:

U.S. Department of Labor, Occupational Safety & Health Administration (OSHA)

Federal OSHA can provide information on safety and health standards on request. OSHA has several offices in New Jersey that cover the following counties:

- Hunterdon, Middlesex, Somerset, Union, and Warren counties….................732-750-3270

- Essex, Hudson, Morris, and Sussex counties…..............................................973-263-1003

- Bergen and Passaic counties…........................................................................201-288-1700

- Atlantic, Burlington, Cape May, Camden, Cumberland, Gloucester, Mercer, Monmouth, Ocean, and Salem counties…........................................856-596-5200

- Web site: www.osha.gov

New Jersey Public Employees Occupational Safety and Health (PEOSH) Program

The PEOSH Act covers all NJ state, county, and municipal employees. Two state departments administer the Act: the NJ Department of Labor and Workforce Development (NJDLWD), which investigates safety hazards, and the NJ Department of Health (NJDOH), which investigates health hazards. PEOSH has information that may also benefit private employers.

NJDLWD, Office of Public Employees Safety

- Telephone: 609-633-3896

- Web site: https://www.state.nj.us/labor/lsse/employer/Occupational_Safety_and_Health_Onsite_Consultation_Program.html

NJDOH, Public Employees Occupational Safety & Health Program

- Telephone: 609-984-1863

- Web site: www.nj.gov/health/peosh

On-site Consultation for Public Employers

- Telephone: 609-984-1863 (health) or 609-633-2587 (safety)

- Web site: www.state.nj.us/health/eoh/peoshweb/peoshcon.html

New Jersey Department of Labor and Workforce Development, Occupational Safety and Health On-Site Consultation Program

This program provides free advice to private businesses on improving safety and health in the workplace and complying with OSHA standards.

- Telephone: 609-984-0785

- Web site: http://lwd.dol.state.nj.us/labor/lsse/employer/ Occupational_Safety_and_Health_Onsite_Consultation_Program.html

New Jersey State Safety Council

The New Jersey State Safety Council provides a variety of courses on work-related safety. There is a charge for the seminars.

- Telephone: 908-272-7712.

- Web site: www.njsafety.org

Internet Resources

Other useful Internet sites for occupational safety and health information:

- CDC/NIOSH – www.cdc.gov/niosh

- USDOL Employment Laws Assistance for Workers and Small Businesses – www.dol.gov/elaws

- National Safety Council – www.nsc.org

- NJDOH FACE reports – www.nj.gov/health/surv/face/index.shtml

- CDC/NIOSH FACE – https://www.cdc.gov/niosh/face/

- OSHA – www.osha.gov

- ANSI – www.ansi.org

REFERENCES

1. Job Hazard Analysis. US Department of Labor Publication # OSHA-3071, 1998 (revised). USDOL, OSHA Publications, PO Box 37535, Washington DC 20013-7535

2. 29 CFR 1910.176(b); Handling materials—general; Secure Storage.

Fatality Assessment and Control Evaluation (FACE) Project

Investigation # 15-NJ-07

This report was prepared by staff members of the New Jersey Department of Health’s Occupational Health Surveillance Unit. The goal of FACE is to prevent fatal work-related injuries by studying the work environment, the worker, the task, the tools the worker was using, the energy exchange resulting in the fatal injury, and the role of management in controlling how these factors interact. FACE gathers information from multiple sources that may include interviews of employers, workers, and other investigators; examination of the fatality site and related equipment; and reviewing OSHA, police, and medical examiner reports, employer safety procedures, and training plans. The FACE program does not determine fault or place blame on employers or individual workers. Findings are summarized in narrative investigation reports that include recommendations for preventing similar events. All names and other identifiers are removed from FACE reports and other data to protect the confidentiality of those who participate in the program.

NIOSH-funded state-based FACE Programs include: California, Iowa, Kentucky, Massachusetts, Michigan, New Jersey, New York, Oregon, and Washington. Please visit the NJ FACE Web site at www.nj.gov/health/surv/face/index.shtml or the CDC/NIOSH FACE Web site at https://www.cdc.gov/niosh/face/ for more information.

The NJ FACE Project is supported by the Centers for Disease Control and Prevention (CDC). The contents of this report are solely the responsibility of the authors and do not necessarily represent the official views of the CDC.