Michigan FACE Information Sheet: Look for Mobile Equipment Blind Spots

-

Fatality Assessment and Control Evaluation (FACE) Program Reports

The National Institute for Occupational Safety and Health’s (NIOSH) Fatality Assessment and Control Evaluation (FACE) Program and State FACE Programs study fatal workplace injuries and prepare reports with recommendations to prevent similar injuries. The following are links to all of the items in this collection:

Documents

- Kentucky FACE Report: Commercial Roofer Falls 30 Feet Through a Skylight While Installing Roof Insulation

- Fatal Occupational Injuries in Massachusetts 2008-2013

- Fatality Assessment & Control Evaluation (FACE) Program

- Washington FACE Report: Glazier Foreman Falls From Stepladder

- Preventing Construction Falls Toolkit

- Hazard Alert: Pedestrian Workers Killed by Forklifts

- Keep Employees in Motor Vehicles Safe

- New York FACE Brochure

- Washington FACE Report: Construction Laborer Falls When Ladder Breaks

- Washington FACE Report: Pipelayer Dies when Trench Wall Collapses

- Washington FACE Report: Carpenter Falls 60 Feet from Bridge Concrete Form

- Washington FACE Report: Foreman and Laborer Fall when Aerial Lift Struck by Vehicle

- Washington FACE Report: Framer Falls 18 Feet while Sheathing Roof

- New York FACE Report: Mechanic Electrocuted when a Mobile Light Tower Contacted Powerline

- New York FACE Report: Two Construction Workers Fatally Crushed when Cement Formwork Collapsed

- Kentucky FACE Report: Construction Laborer Killed in Trench Collapse while Taking Grade Measurements

- California FACE Report: A Heating, Ventilaton and Air Conditioning (HVAC) Contractor Dies when He Falls through a Skylight

- Massachusetts FACE Report: Carpenter Fatally Injured after Falling from an Extension Ladder

- Massachusetts FACE Report: Laborer Fatally Injured after Falling from a Home under Construction

- Oregon FACE Report: Worker Falls When Ladder Slips

- Michigan FACE Information Sheet: Look for Mobile Equipment Blind Spots

- Oregon FACE Report: Collapsed roof trusses kill carpenter foreman

- Washington FACE Report: Roofer Falls 19 Feet from Roof

- Hazard Alert: Plan. Provide. Train. Prevent Fall Injuries & Deaths

- Kentucky FACE Report: 19-Year-Old Construction Laborer Crushed in Trench Collapse While Laying Sewage Pipe

- Kentucky FACE Report: Construction Flagger Struck and Killed in Two-Lane Highway Work Zone

- Kentucky FACE Report:Temporary Electrician Helper Steps into Unguarded Elevator Shaft and Dies

- Fatality Narrative: Roofing Contractor Falls 25 Feet From Church Roof

- Kentucky FACE Report: Construction Siding Subcontractor Installer Killed when Oversized Scaffolding Platform Destabilized and Telescopic Forklift Overturned

- NIOSH FACE Report - Maintenance Worker Struck by Forklift Carriage—Tennessee

- Kentucky Hazard Alert: Roofing and Construction Workers Killed Due to High Winds

- Poster: Secure it to move it!

- Oregon FACE Report: Crane Operator Killed By Falling Steel Beam

- New Jersey FACE Report: Mechanic Dies After Being Crushed Under Electrical Cabinet

- New Jersey FACE Report: Plant Manager Crushed to Death Under Fallen Pile of Steel Beams

- NIOSH FACE Report: Hispanic worker falls from residential roof

- Oregon FACE Report: Construction worker died after falling 20-25 feet from a pump-jack scaffold

- FACE Fact Sheet: Prevent Construction Falls from Roofs, Ladders, and Scaffolds

- Construction Fatality Narrative: Roofer Falls 18 Feet from Wet House Roof

- Construction Worker Killed when Trench Collapsed, Oregon

- A Tree Trimmer is Electrocuted While Trimming a Palm Tree

- A Tree Feller Dies When Struck By a Tree Limb While Felling a Fire-Damaged Tree

- Concrete Finisher Electrocuted When Bull Float Contacted an Energized Power Line

- Warehouse Worker Crushed by Forks of Laser Guided Vehicle

Summary Statement

This Michigan Fatality Assessment and Control Report reviews fatal back-up injuries caused by vehicle blind spots and presents measures for prevention.

August 2011

Investigation/Research

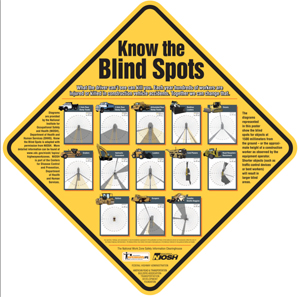

LOOK FOR MOBILE EQUIPMENT BLIND SPOTS

Fifteen (15) work-related fatalities have occurred since 2001 while a vehicle was backing up. Construction activities accounted for 9 of these fatalities; dump trucks were involved in 5 fatalities. Other vehicle types include an airport tug, a farm tractor, a cement mixer, a forklift, a fuel truck, a utility bucket truck, a road grader, a window delivery truck, and a semi-truck. A blind spot is the area around a vehicle or piece of contruction equipment that is not visisble to operators, either by direct line-of sight or indirectly by use of internal and external mirrors. Use Spotters wearing reflective vests when the driver has an obstructed view; the truck contains extended components (such as a crane); or when someone or something could enter the driver's backing path.

IN ORDER TO PREVENT SIMILAR INCIDENTS IN THE FUTURE

-

Install after-market presence detectors on vehicles. Systems include cameras, additional mirrors, ultrasonic sensing and radar.

- Develop Standard Operating Procedure (SOP) for backing vehicles.

- Develope Driver backing vehicle training. Training should include: driver stopping vehicle if he'she cannot see the Spotter, performing a walk-around to determine obstacles/hazards and site/vehicle clearances, sounding horn prior to backing, and demonstrating backing competency.

- Develop Spotter backing vehicle training. Training should include: signals to be used and agreed upon with driver, maintaining eye contact and a safe distance from backing behicle on the driver's side, and demonstrating spotter competency.

- Learn vehicle's blind spots. Consult NIOSH Highway Work Zone Safety, Construction Vehicle List (See NIOSH web reference). If vehicle not listed, estimate vehicle blind zone: Sit in driver's seat, have another person walk away from vehicle until driver can see his/her feet, measure distance. For side and rear, repeat process using side/rear view mirrors. Area within measured distance is blind zone.

- Develop an Internal Traffic Control Plan (ITCP) to reduce vehicle backing in work zones and to establish truck lanes and pedestrian walk paths.

- Ensure Worker Visibility. Specify appropriate class of high-visibility vests/clothing. (See ANSI/ISEA 107-2010 web reference)

DID YOU KNOW?

- On average, each year there are 292 fatalities and 18,000 injuries each year as a result of a vehicle backing up. (NHTSA)

- You can minimize blind spots as you travel on-the-road. (From National Safety Council)

- Driver's side mirror: Sit in driver's seat

- Roll up window and lean head against it

- Adjust driver's side mirror to point just past where you can see your car.

- Passenger side mirror: Sit in driver's seat

- Lean toward center of vehicle

- Adjust passenger side mirror to point just past where you can see your car.

- Consumer Reports.org measured the best and worst of passenger vehicle blind spots: http://www.consumerreports.org/cro/2012/03 /the-danger-of-blind-zones/index.htm

MSU Occupational and Environmental Medicine:

www.oem.msu.edu/

NIOSH Highway Work Zone Safety:

www.cdc.gov/niosh/topics/highwayworkzones/

MIOSHA Standards

www.michigan.gov/mioshastandards

High Visibility Clothing - ANSI/ISEA 107-2010:

https://safetyequipment.org/ansiisea-107-2015/

TO REPORT A NEW WORKPLACE FATALITY TO MIOSHA

1-800-858-0397

Information: 1-517-353-1846

E-mail: debra.chester@ht.msu.edu